Method and device for de-oiling oil-based mud rock debris through rotation by rotary flow

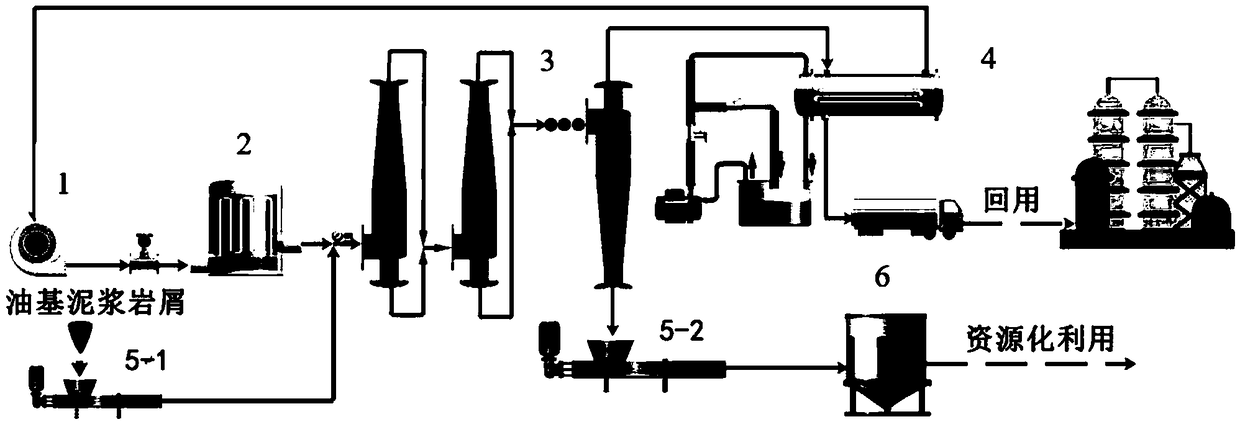

An oil-based mud and cuttings technology, which is applied in the field of environmental protection treatment of oily solid waste in shale gas drilling, can solve problems such as difficult oil separation, secondary pollution, complex process, etc., to reduce energy consumption and improve oil removal efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] For oil-based mud drilling in a shale gas block, oil-removal treatment of waste oil-based mud is carried out according to the method and device of the present invention. The specific operation process and effects are described as follows:

[0061] 1. Physical and chemical properties test of oil-based mud cuttings samples

[0062] 1) Oil, water and solid three-phase content test

[0063] Using a Soxhlet extractor and CCl 4 The waste oil-based mud cuttings were extracted with solvent, and the oil content of the sample was measured by an infrared spectrophotometer to be 19.4%. After drying, the solid content of the sample was 63.1%, and the water content was 17.5%.

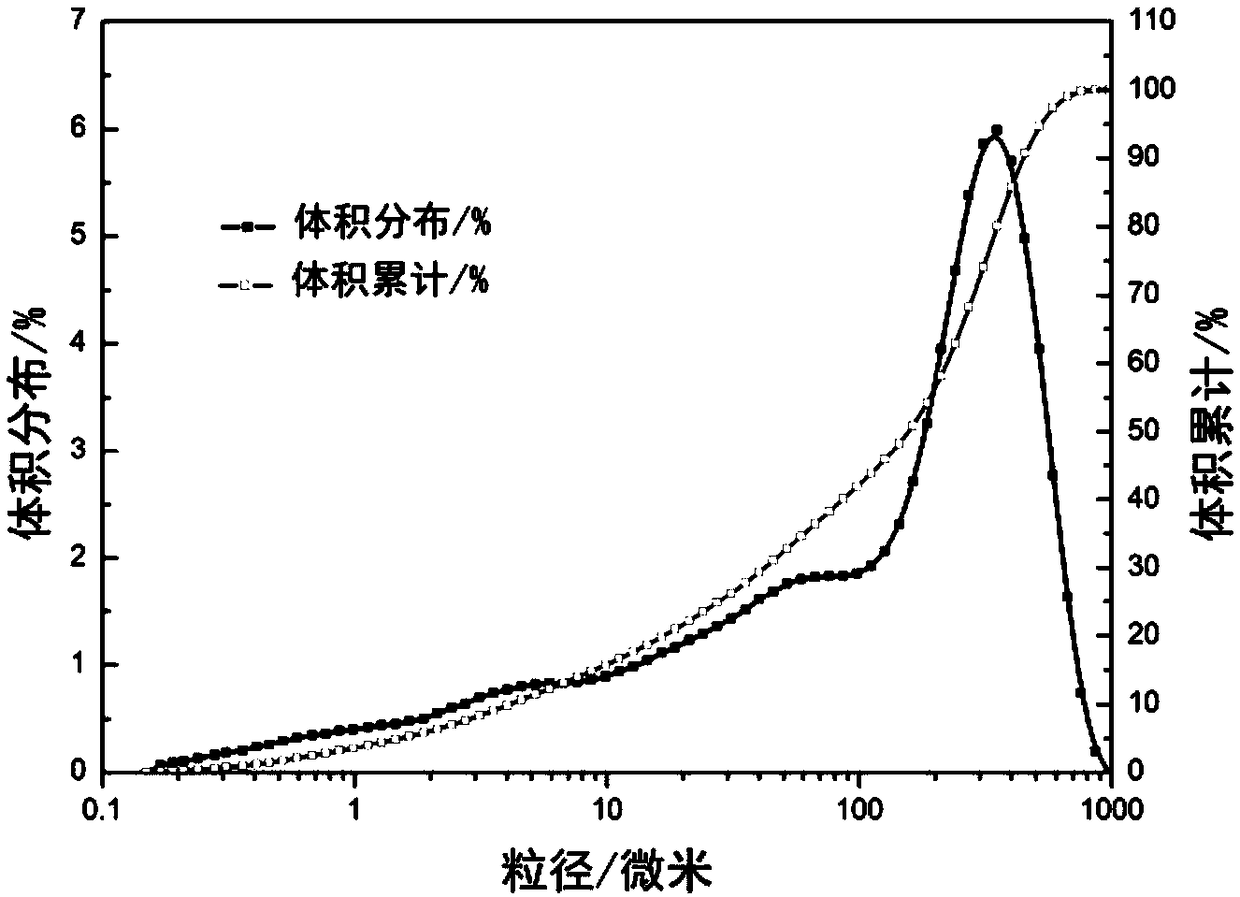

[0064] 2) Particle size test of cuttings

[0065] The particle size of cuttings particles directly affects the size of the centrifugal force it receives in the cyclone. The particle size distribution of cuttings particles after extraction is measured by laser particle size analyzer as follows: figure 2 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com