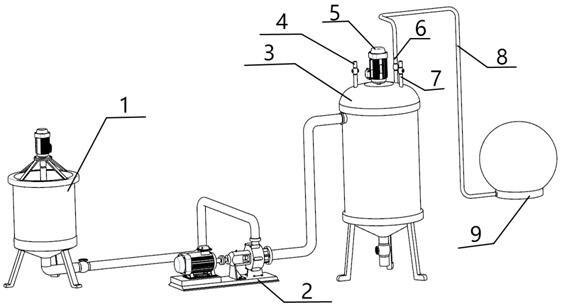

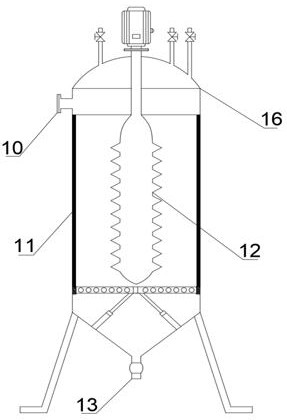

A method and device for stabilizing heavy metals in anaerobic fermentation sludge by electrocatalysis

An anaerobic fermentation and heavy metal technology, applied in electrochemical sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc., can solve the long time period of anaerobic digestion and composting, and the low efficiency of sludge recycling , failure to achieve the purpose of capacity reduction, etc., to achieve the effect of improving the stabilization effect, high sludge fertilizer efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

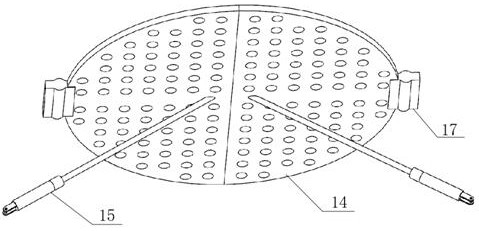

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: The processing object of this embodiment is A of a certain sewage treatment plant 2 Dewatered sludge treated by / O process, the main mud index: pH is 6.2, moisture content is 80%, VS is 50%; the heavy metal content of activated sludge in this plant is Cu 220mg / kg, Zn1100mg / kg, Ni 30mg / kg, Pb 150mg / kg; see Table 1 for the weight percentages of the five forms of the four heavy metals in the original activated sludge in their respective total amounts.

[0042] Table 1 Percentage of various forms of heavy metals in raw activated sludge

[0043]

[0044] 1. Sludge pretreatment

[0045] Add humus, nanometer zero-valent iron, and domesticated microbial bacterial liquid into the regulating tank and stir and mix with the above-mentioned dewatered sludge; wherein the domesticated microbial bacterial liquid is obtained by using A 2 The solid-liquid mixture in the anaerobic tank of the O process sewage treatment plant is domesticated at a voltage of 1.5V for 2 w...

Embodiment 2

[0055] Embodiment 2: The processing object of this embodiment is A of a certain sewage treatment plant 2 / O process dewatered sludge, the main mud index: pH 6.5, moisture content 85%, VS 55%; heavy metal content of activated sludge in this plant is Cu: 250, Zn: 1200, Ni: 35, Pb: 140 (mg / kg). See Table 3 for the weight percentages of the five forms of the four heavy metals in the original activated sludge in their respective total amounts.

[0056] Table 3 Percentage of various forms of heavy metals in raw activated sludge

[0057]

[0058] 1. Sludge pretreatment

[0059] Humus, nano-Fe 3 o 41. Add the domesticated microbial liquid into the regulating tank and mix it evenly with the above-mentioned dewatered sludge; wherein the domesticated microbial liquid is obtained by using A 2 The solid-liquid mixture in the anaerobic tank of the O process sewage treatment plant is domesticated for 3 weeks at a voltage of 2.5V. The amount of the domesticated microbial bacterial sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com