Preparation method capable of improving efficiency of thin film solar cell

A solar cell and efficiency technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of module efficiency and light decay rate, differences in film characteristics in corner areas, and low efficiency of "sub-cells", achieving The effect of considerable economic benefits, wide application range, and stable efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is described further below:

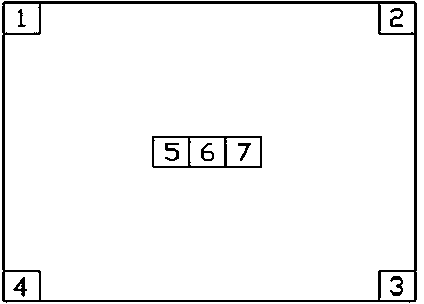

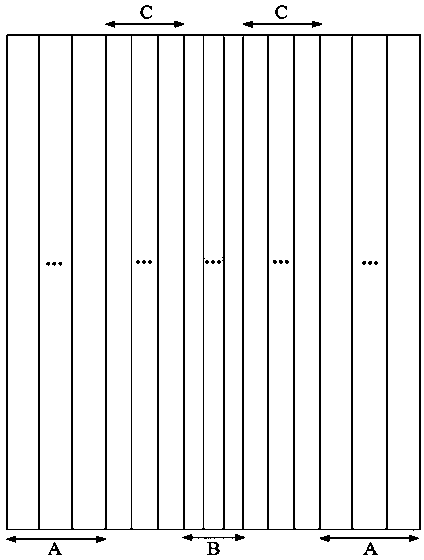

[0026] For a 1.1m×1.3m battery panel, the current usual marking method is: marking the entire battery into 99 "sub-batteries" with a width of 1.0768 cm. The present invention changes the marking method of the entire battery from a uniform method to It is divided into three regions to modulate the width of the sub-cells respectively. like figure 2 and image 3 As shown, the manufacturing process of the present invention is divided into the following steps:

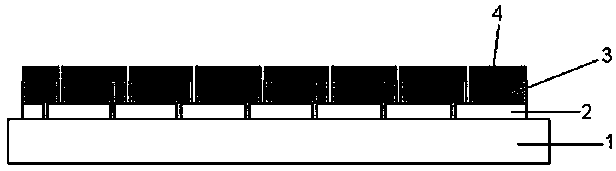

[0027] (1) Provide a substrate 1 coated with a light-transmitting conductive oxide layer 2 with a thickness of 1-2 μm on the surface;

[0028] (2) passing the laser beam through the substrate 1 to the conductive oxide layer 2, and scribing to penetrate the conductive oxide layer 2 to form a first groove;

[0029] (3) Plating a semiconductor photoelectric conversion layer 3 with a thickness of 0.5-2 μm on the surface of the conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com