Method for soiling metal tailings and stabilizing heavy metals

A technology of metal tailings and soilization, applied in the field of environmental governance and restoration, can solve the problems of less collaborative research on tailings heavy metal stabilization and tailings soilization, incomplete processing, and many procedures, achieving low cost and convenient processing , the effect of protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

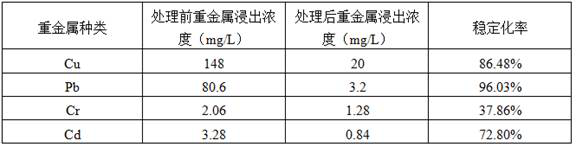

Embodiment 1

[0026] Coal gangue is dried, crushed, and then sieved to obtain coal gangue powder, and the urban sludge is air-dried to obtain air-dried urban sludge; the tailings to be treated are turned over, and 5% of the tailings mass is added to the gangue powder and 5% The air-dried urban sludge is mixed evenly, and then 3% tailing mass stabilizer and water are added, and the mixture is continued to be evenly mixed to obtain a mixture with a solid-liquid ratio of 1:0.2, which is then left to stand for 1 month.

Embodiment 2

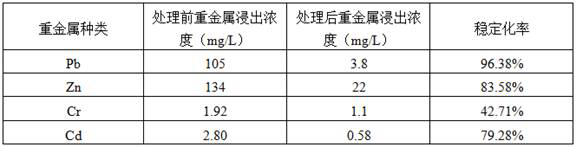

[0028] Coal gangue is dried, crushed, and then sieved to obtain coal gangue powder, and the urban sludge is air-dried to obtain air-dried urban sludge; the tailings to be treated are turned over, and 10% of the tailings mass is added to the gangue powder and 10% The air-dried urban sludge is mixed evenly, and then the stabilizing agent with 13% tailings mass and water are added, and the mixture is continued to be evenly mixed to obtain a mixture with a solid-liquid ratio of 1:0.3, which can be left to stand for 2 months.

Embodiment 3

[0030] Coal gangue is dried, pulverized, and then sieved to obtain coal gangue powder, and the urban sludge is air-dried to obtain air-dried urban sludge; the tailings to be treated are turned over, and coal gangue powder with 7.5% of the tailings mass and 7.5% The air-dried urban sludge is mixed evenly, and then 8% of the tailing mass stabilizer and water are added, and the mixture is continued to be evenly mixed to obtain a mixture with a solid-liquid ratio of 1:0.25, which is then left to stand for 1.5 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com