Stabilizing agent for repairing arsenic slag and application method of stabilizing agent

An application method and stabilization technology, applied in the field of stabilization agents for repairing arsenic slag, can solve the problems of unsuitability for large-scale production, unsatisfactory repair effect, cumbersome repair process, etc., so as to reduce the number of mechanical shifts and reduce the risk of leaching. , The effect of the treatment process is feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

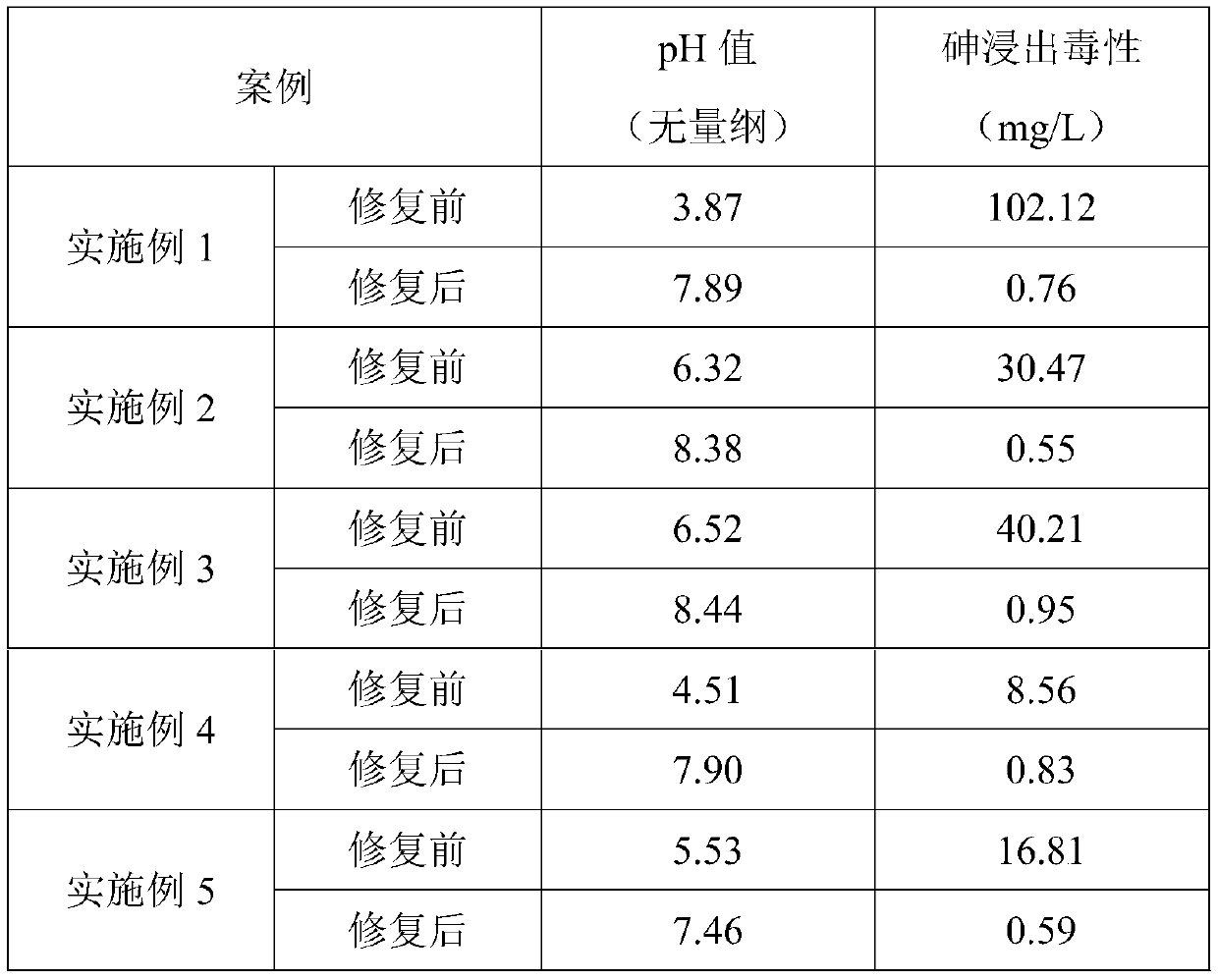

Examples

Embodiment 1

[0040] The test samples were taken from the arsenic slag left over from an abandoned arsenic factory in Wenshan Prefecture, Yunnan. The restoration steps are as follows:

[0041] 1) Preparation method of stabilizing agent

[0042] Calcium oxide and polyferric sulfate are mixed and then ground and pulverized by a ball mill. The mass ratio of calcium oxide and polyferric sulfate is 1:1, and the specific surface area of the finished product is 17.2m 2 / g, the mesh number is 800 mesh, and the moisture content is ≤0.3%;

[0043] 2) Application method of stabilizing agent for repairing arsenic slag

[0044]First air-dry the arsenic slag / arsenic-contaminated soil until the moisture content is ≤15%, and then use mobile crushing and screening equipment to crush to a particle size of ≤10mm to obtain a slag pile; then add 12% (based on slag heap dry basis mass), and use a crushing and screening bucket to mix the agent and the slag heap evenly; then add clear water to the slag heap wi...

Embodiment 2

[0046] The test samples were taken from the arsenic slag left over from an abandoned arsenic factory in Wenshan Prefecture, Yunnan. The restoration steps are as follows:

[0047] 1) Preparation method of stabilizing agent

[0048] Calcium oxide, polyferric sulfate, and polyferric aluminum sulfate are mixed and then ground and pulverized by a ball mill. The mass ratio of calcium oxide, polyferric sulfate and polyferric aluminum sulfate is 1:0.6:0.6, and the specific surface area of the finished product is 14.6m 2 / g, the mesh number is 700 mesh, and the moisture content is ≤0.3%;

[0049] 2) Application method of stabilizing agent for repairing arsenic slag

[0050] First air-dry the arsenic slag / arsenic-contaminated soil to a moisture content of ≤15%, and then use mobile crushing and screening equipment to crush to a particle size of ≤10mm to obtain a slag heap; then add 8% (based on slag heap dry basis mass), and use a crushing and screening bucket to mix the agent and th...

Embodiment 3

[0052] The test samples were taken from the arsenic slag left over from an abandoned arsenic factory in Wenshan Prefecture, Yunnan. The restoration steps are as follows:

[0053] 1) Preparation method of stabilizing agent

[0054] Calcium oxide and polyferric sulfate are mixed and then ground and pulverized by a ball mill. The mass ratio of calcium oxide to polyferric sulfate is 0.7:1, and the specific surface area of the finished product is 17.4m 2 / g, the mesh number is 650 mesh, and the moisture content is ≤0.3%;

[0055] 2) Application method of stabilizing agent for repairing arsenic slag

[0056] Air-dry the arsenic slag / arsenic-contaminated soil to a moisture content of ≤15%, and then crush it to a particle size of ≤10mm with mobile crushing and screening equipment to obtain a slag heap; then add 9% (based on slag heap dry basis mass), use the crushing and screening bucket to mix the agent and the slag heap evenly; then add clear water to the slag heap with the agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com