Electric arc molten processing system and method for processing rubbish combustion ash

A technology of waste incineration ash and treatment system, which is applied in the field of electric arc melting treatment system and its treatment of waste incineration ash, can solve the problems of no melting device and melting treatment method, inability to eliminate dioxin organic poison, poor volume reduction effect, etc. Achieve good curing effect, significant environmental protection and economic benefits, and relieve landfill land tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

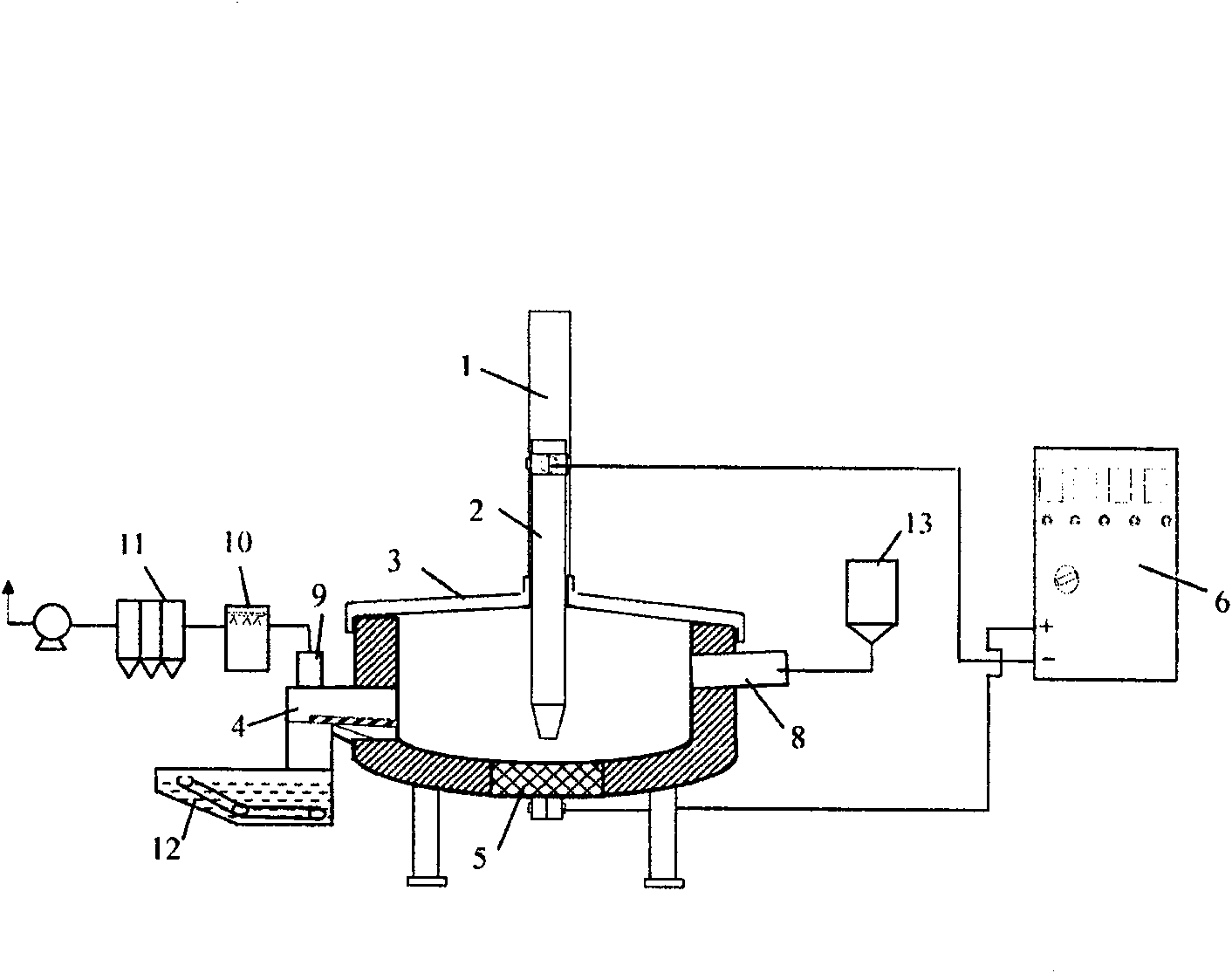

[0041] In the figure: 1-support; 2-top electrode; 3-water-cooled furnace cover; 4-slag outlet; 5-bottom electrode; 6-DC power supply; 7-furnace body; ; 10-quick cooling device; 11-bag filter; 12-water cooling tank; 13-feeding system.

[0042] as attached figure 1 As shown, the present invention is an arc melting processing system, which includes: a feeding system 13, which uses a conveyor belt to transport materials; Discharge after treatment; the slag cooling system is to cool and solidify the melted solids; the arc melting treatment system also includes an electric arc furnace, which is the core of the entire system, and is used to melt waste incineration ash; the furnace body of the electric arc furnace 7 It is a circular container structure with an upper opening, and its inner cavity is used as a melting pool for processing waste incineration ash; the opening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com