Lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer and preparation method and application thereof

A technology of triaminotriethylamine salt and triaminotriethylamine potassium salt, which is applied in the field of environmental protection technology and municipal solid waste incineration fly ash disposal, can solve the application and promotion of difficult industrialized scale, the effect of heavy metal disposal is not obvious, and the stabilizer The problem of high synthesis cost can achieve the effect of good volume reduction effect, lower synthesis cost and good flocculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer has the following steps:

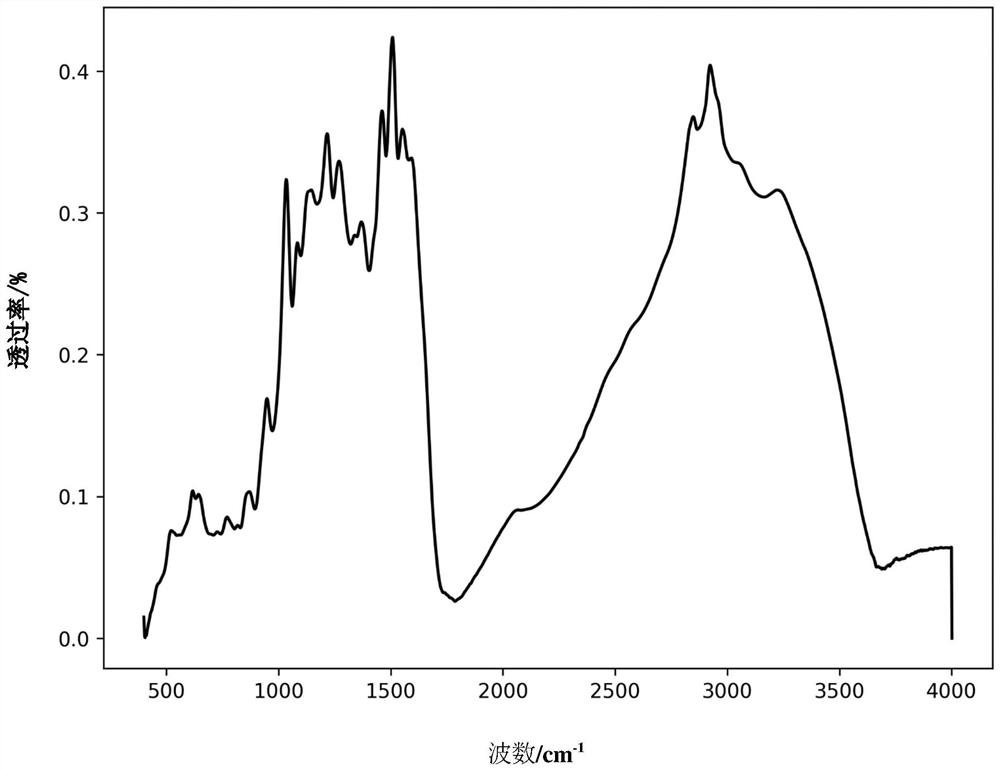

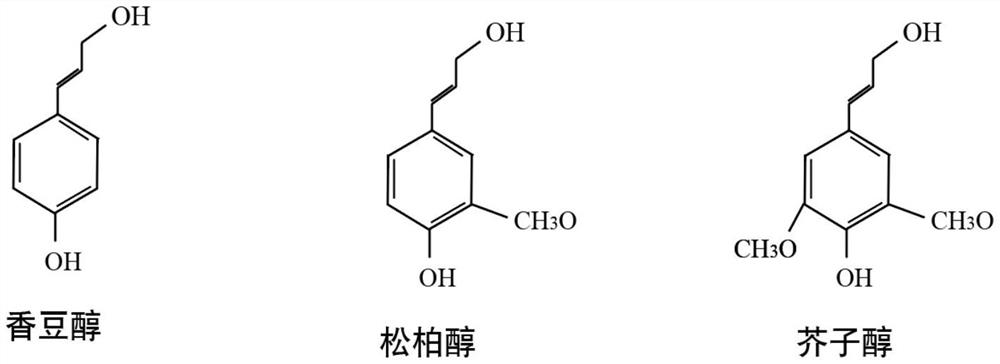

[0048] Under normal pressure and temperature, weigh 50g of anhydrous alkaline lignin, add deionized water to configure a mixed solution with a mass fraction of 30%, put it into a three-necked flask, add 1mol / L NaOH dropwise to adjust the pH to 10, Add 6.94g of 30% hydrogen peroxide under magnetic stirring state, oxidize at a stable temperature of 90°C, and react for 1 hour to obtain a mixed liquid of oxidized lignin;

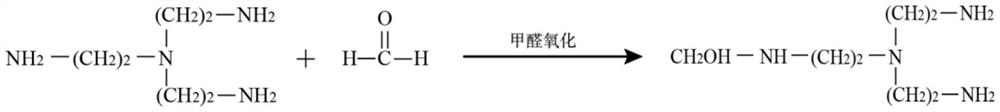

[0049] Take 22.82g of 2,2',2"-triaminotriethylamine and place it in a beaker, slowly add 9.375g of formaldehyde dropwise through an automatic titrator (drip in half an hour), stabilize the reaction temperature at 90°C, 2,2',2 "-Triaminotriethylamine replaces the hydrogen in formaldehyde and reacts for 1 hour; put the obtained oxidized triaminotriethylamine into a three-necked flask, mix it with the oxidized lignin ...

Embodiment 2

[0054] The preparation method of lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer has the following steps:

[0055] Under normal pressure and temperature, weigh 30g of anhydrous alkaline lignin, add deionized water to configure a mixed solution with a mass fraction of 30%, put it into a three-necked flask, add 1mol / L NaOH dropwise to adjust the pH to 11, Add 4.23g of 30% hydrogen peroxide under magnetic stirring state, carry out oxidation at a stable temperature of 80°C, and react for 2 hours to obtain a mixed liquid of oxidized lignin;

[0056] Take 14.28g of 2,2',2"-triaminotriethylamine and place it in a beaker, slowly add 6.325g of formaldehyde dropwise through an automatic titrator (drip in half an hour), stabilize the reaction temperature at 80°C, 2,2',2 "-Triaminotriethylamine replaces the hydrogen in formaldehyde and reacts for 2 hours; put the obtained oxidized triaminotriethylamine into a three-necked flask, mix it with the ox...

Embodiment 3

[0060] The preparation method of lignin-based triaminotriethylamine salt waste incineration fly ash heavy metal stabilizer has the following steps:

[0061] Under normal pressure and temperature, weigh 80g of anhydrous alkaline lignin, add deionized water to configure a mixed solution with a mass fraction of 30%, put it into a three-necked flask, add 1mol / L NaOH dropwise to adjust the pH to 9, Add 11.12g of 30% hydrogen peroxide under magnetic stirring state, and carry out oxidation at a stable temperature of 90° C., and react for 2 hours to obtain a mixed liquid of oxidized lignin;

[0062] Take 36.53g of 2,2',2"-triaminotriethylamine and place it in a beaker, slowly add 15.28g of formaldehyde dropwise through an automatic titrator (drip in half an hour), stabilize the reaction temperature at 90°C, 2,2',2 "-Triaminotriethylamine replaces the hydrogen in formaldehyde and reacts for 2 hours; put the obtained oxidized triaminotriethylamine into a three-necked flask, mix it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com