Radioactive waste curing method

A technology of radioactive waste and solidification method, which is applied in the fields of radioactive purification and nuclear engineering, which can solve the problems of increased waste volume and disposal costs, and achieve the effects of avoiding the reduction of waste body stability, good physics, and large containment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

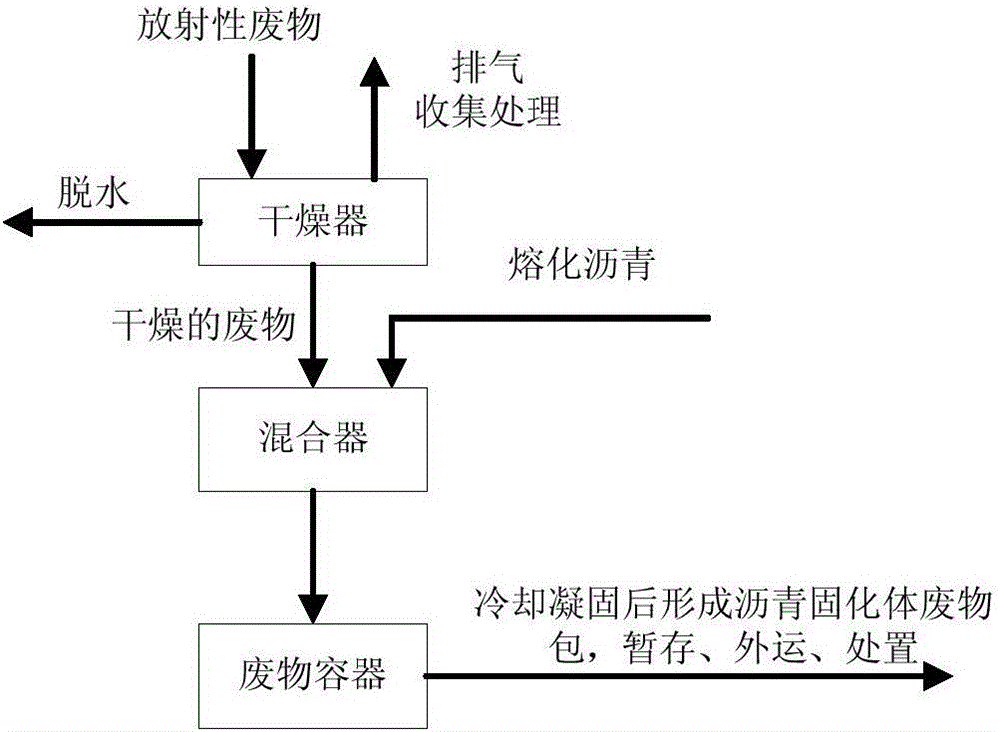

[0054] figure 1 A set of apparatus for carrying out the method of the invention is shown, said apparatus comprising a dryer, a mixer and a waste container. Concrete curing method comprises the following steps:

[0055] 1) The radioactive waste resin is first sent to the drier, and dehydrated through the filter set at the lower part of the drier until the water content is less than the predetermined value.

[0056] 2) After dehydration, the radioactive waste resin is dried at a temperature of 100-250°C.

[0057] Generally, the higher the drying temperature and the longer the drying time, the greater the volume and weight reduction of radioactive waste resin. The volume and weight of radioactive waste resin can usually be reduced to less than half after drying.

[0058] The drying temperature of other radioactive waste can be controlled according to actual needs.

[0059] The gas produced by the drying of radioactive waste resin is mainly water vapor and a part of the active c...

Embodiment 2

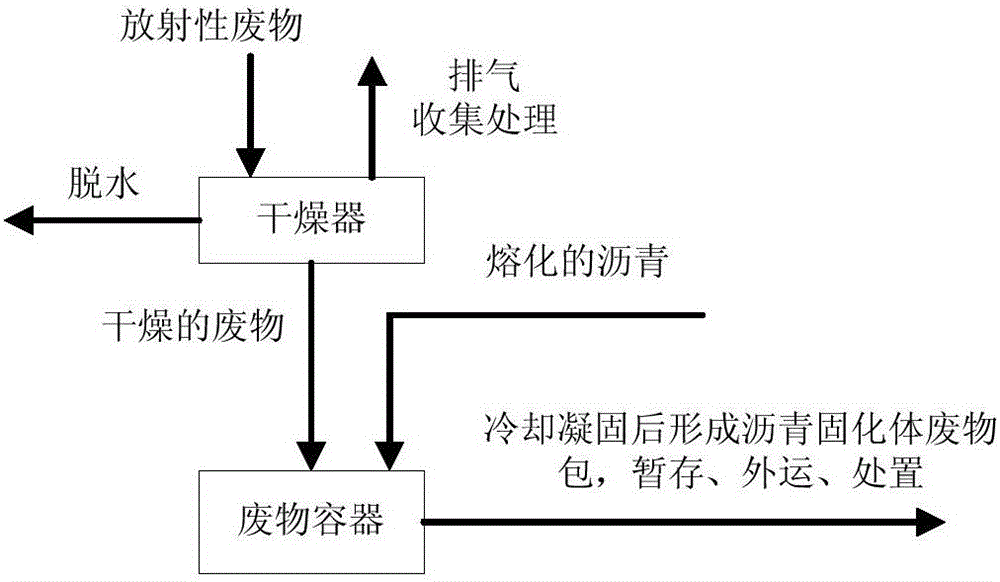

[0064] figure 2 A set of apparatus for carrying out the method of the invention is shown, said apparatus comprising a dryer and a waste container.

[0065] The specific solidification method can refer to Example 1, the difference is that the mixing step and the cooling and solidification step are all carried out in a waste container.

[0066] The present invention uses bitumen solidification to treat radioactive waste resin or other wastes. Because the operation temperature of controlling bitumen melting and mixing is low (100-130° C.), the mixture does not contain or contains very little strong oxidants such as sodium nitrate, and is used Good ventilation is maintained during the drying and asphalt curing process, so fire accidents are less likely. Even so, if necessary, a corresponding fire extinguishing system should be set up to prevent fire accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com