Cyanobacteria dehydrated algal mud waste treatment process

A technology for waste treatment and algal mud, which is applied in radiation treatment, biological organic part treatment, heating/cooling of fertilizer treatment, etc., can solve the problems of long treatment time, large odor, ecological environment damage, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

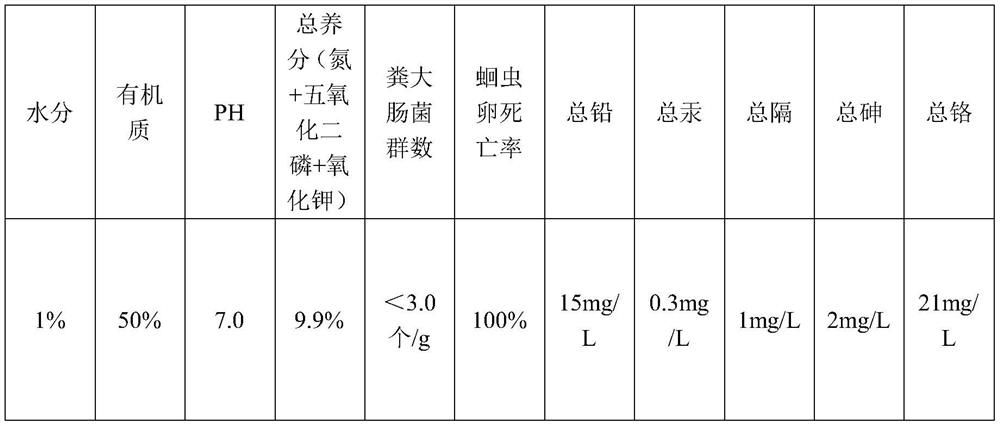

Examples

Embodiment Construction

[0022] The specific implementation of this embodiment will be described below in conjunction with the accompanying drawings.

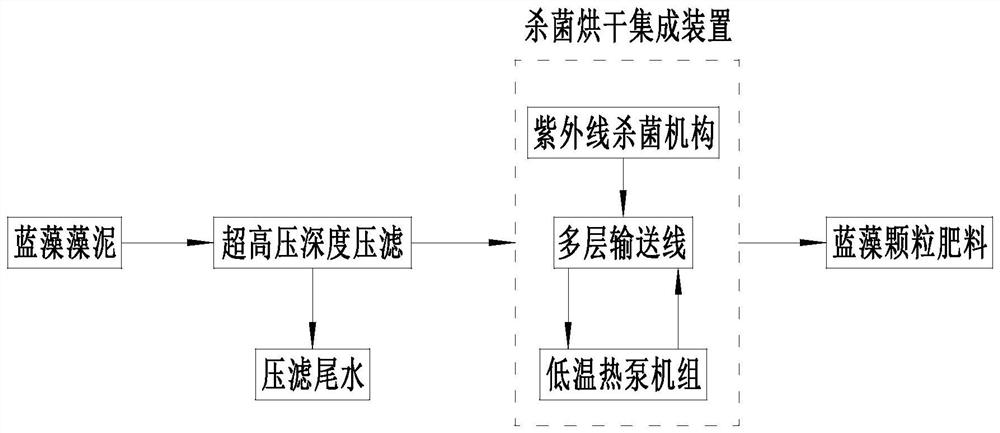

[0023] Such as figure 1 As shown, the cyanobacteria dehydrated algae mud waste treatment process of the present embodiment comprises the following steps:

[0024] 1) Ultra-high pressure deep pressure filtration: no conditioning agent is added to the algae mud, and it is directly sent to the vertical filter press for pressure filtration operation. The pressure range of the vertical filter press is 5MPa ~ 10MPa to reduce the content of The amount of water is to remove 50% to 60% of the water in the algae mud, so that the water content of the algae mud cake after pressure filtration can be in the range of 70% to 75%, which can reduce the weight of the algae mud cake to the original 40% to 50%. The tail water produced by the filtration is sent to the water treatment equipment to be treated and discharged after reaching the standard;

[0025] 2) Steriliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com