Garbage cracking purification device and garbage cracking purification treatment process

A technology for purifying equipment and garbage, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. It can solve the problems of ineffective disinfection, high operating cost, and large energy consumption, and achieve good effect of volume reduction , avoiding secondary pollution and garbage destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

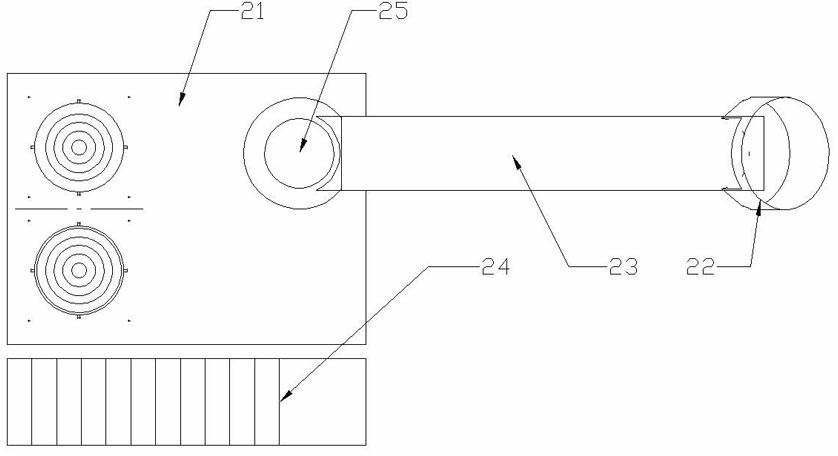

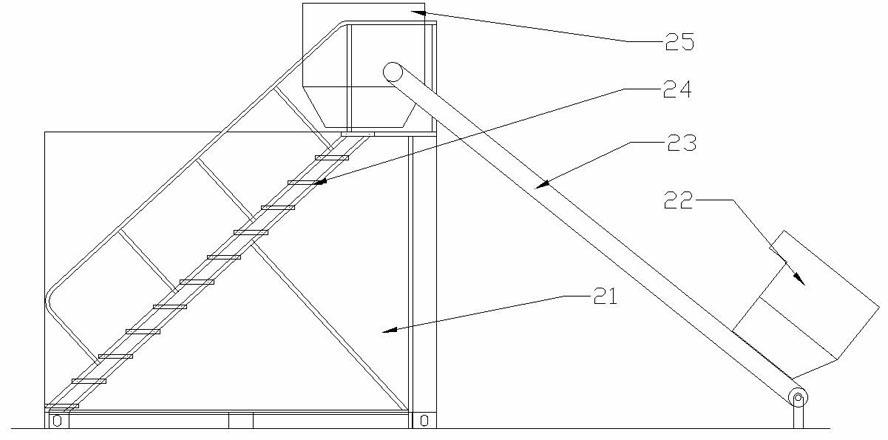

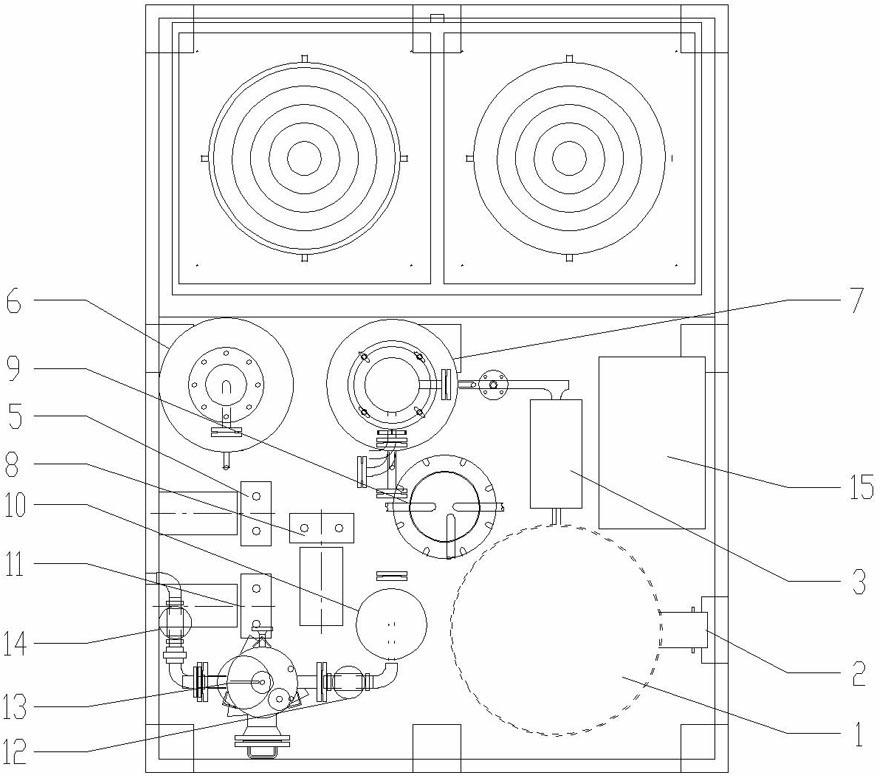

[0027] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the garbage cracking and purification equipment of the present invention includes a housing 21 and a feeding and conveying device. A cracking furnace body 1, a gas absorption tank 7, an ultra-high frequency power supply host 15, and a lye container 18 are installed in the housing 21. , gas purification adsorption tower 13, described pyrolysis furnace body of furnace 1 is used for high temperature pyrolysis dry, wet medical treatment, household etc. rubbish, makes rubbish component decompose completely, and its outward appearance can be divided into vertical, side type or horizontal; So The upper and lower parts of the cracking furnace body 1 are respectively provided with a feed inlet and a solid slag discharge port 2, and the feeding conveying device is connected with the feed inlet of the cracking furnace body 1, and the cracking furnace body 1 is connected with the gas absorption A gas cracking part 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com