Method for preparing high-strength lightweight aggregate from municipal sludge

A municipal sludge, high-strength technology, applied in the field of municipal environmental engineering, can solve the problems of waste discharge, loose ceramsite structure, poor compressive effect, etc., to eliminate environmental hazards, improve compressive strength, and improve dehydration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

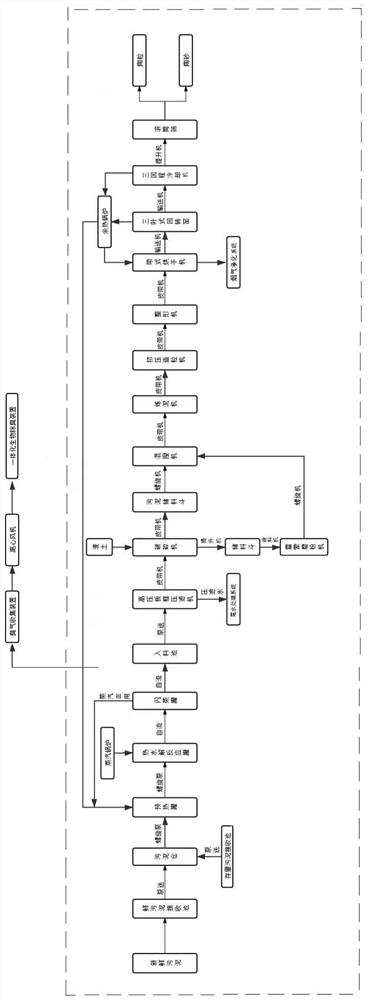

[0027] The method of utilizing municipal sludge to prepare high-strength lightweight aggregate provided in this embodiment, its technological process is as follows figure 1 As shown, the specific steps are as follows:

[0028] (1) Sludge pretreatment:

[0029] a. Municipal sludge: The sludge from the sewage treatment plant is transported by vehicle to the fresh sludge receiving pool of the sludge centralized disposal plant.

[0030] b. Stock sludge: the slurry is excavated by hydraulic force and pumped to the stock sludge receiving tank

[0031] The sludge in the fresh sludge receiving tank is pumped to the sludge bin, and mixed with the stock sludge to form a slurry with an initial moisture content of 94%.

[0032] (2) Thermal hydrolysis: send the mud in the sludge silo to the preheating tank for preheating, use the flash steam recovered after the reaction of the waste heat boiler and the flash tank for preheating, and the preheated mud is pumped Send it to the thermal hyd...

Embodiment 2

[0044] The method for preparing high-strength lightweight aggregate from municipal sludge provided in this example, the specific steps are as follows:

[0045] (1) Sludge pretreatment:

[0046] b. Municipal sludge: The sludge from the sewage treatment plant is transported by vehicle to the fresh sludge receiving pool of the centralized sludge disposal plant.

[0047] b. Stock sludge: the slurry is excavated by hydraulic force and pumped to the stock sludge receiving tank

[0048] The sludge in the fresh sludge receiving tank is pumped to the sludge bin, and mixed with the stock sludge to form a slurry with an initial moisture content of 90%.

[0049] (2) Thermal hydrolysis: send the mud in the sludge silo to the preheating tank for preheating, use the flash steam recovered after the reaction of the waste heat boiler and the flash tank for preheating, and the preheated mud is pumped Send it to the thermal hydrolysis reaction tank, inject superheated steam through the steam bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com