A mold for ultra-high pressure hydraulically pressing hazardous waste into high-density modules

A technology for hazardous materials and wastes, which is applied in the field of equipment for processing solid hazardous materials and waste, can solve problems such as inappropriate pressing operations, and achieve the effects of reducing dust hazards, reducing landfill volume, and reducing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the scope expressed by the examples.

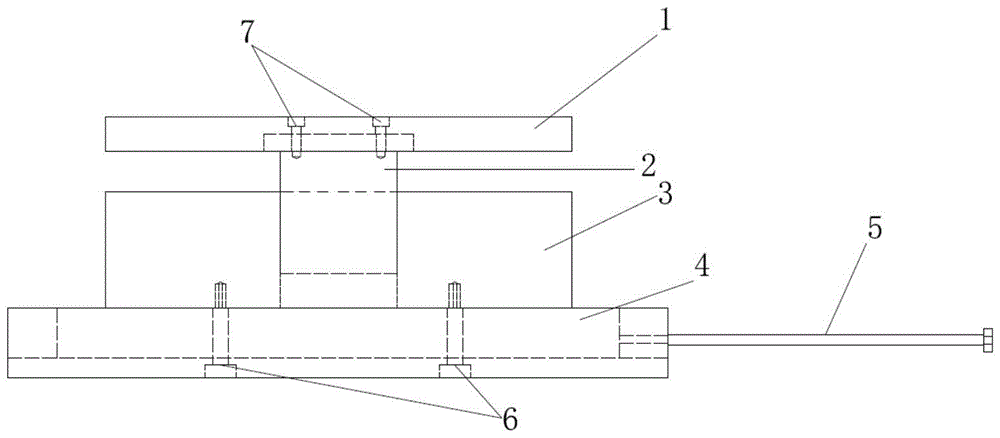

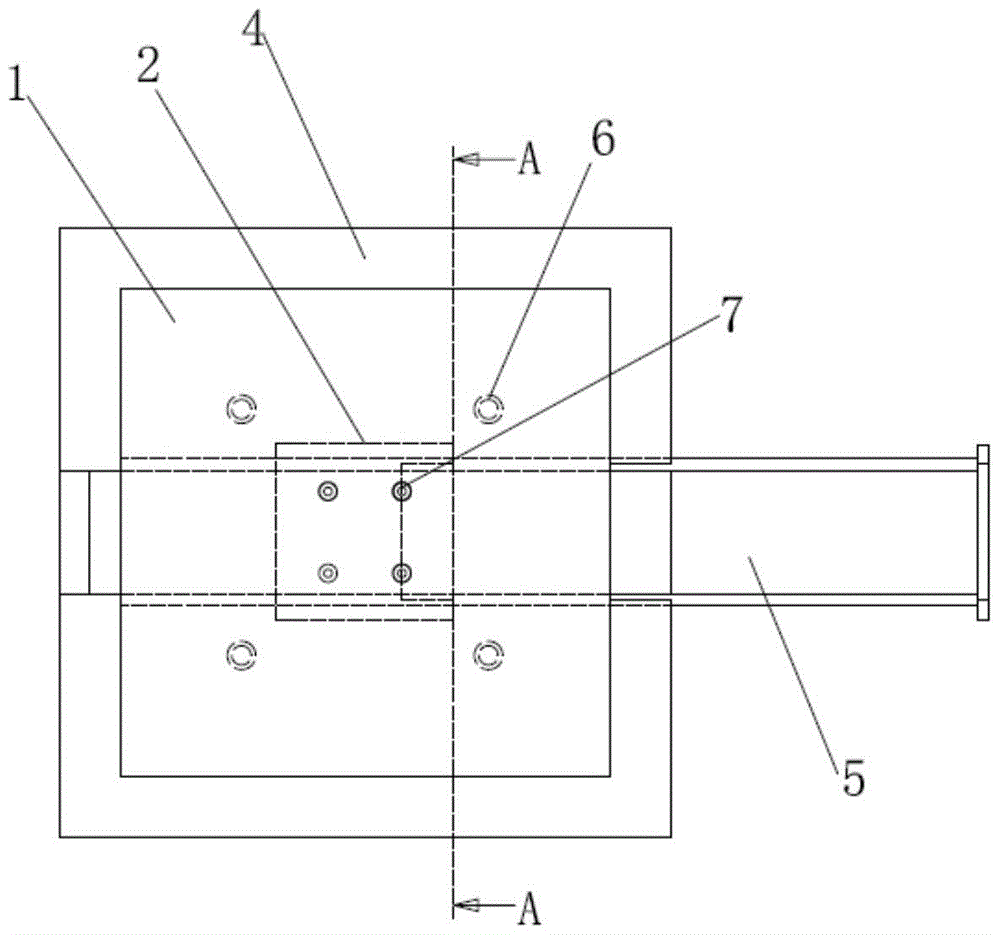

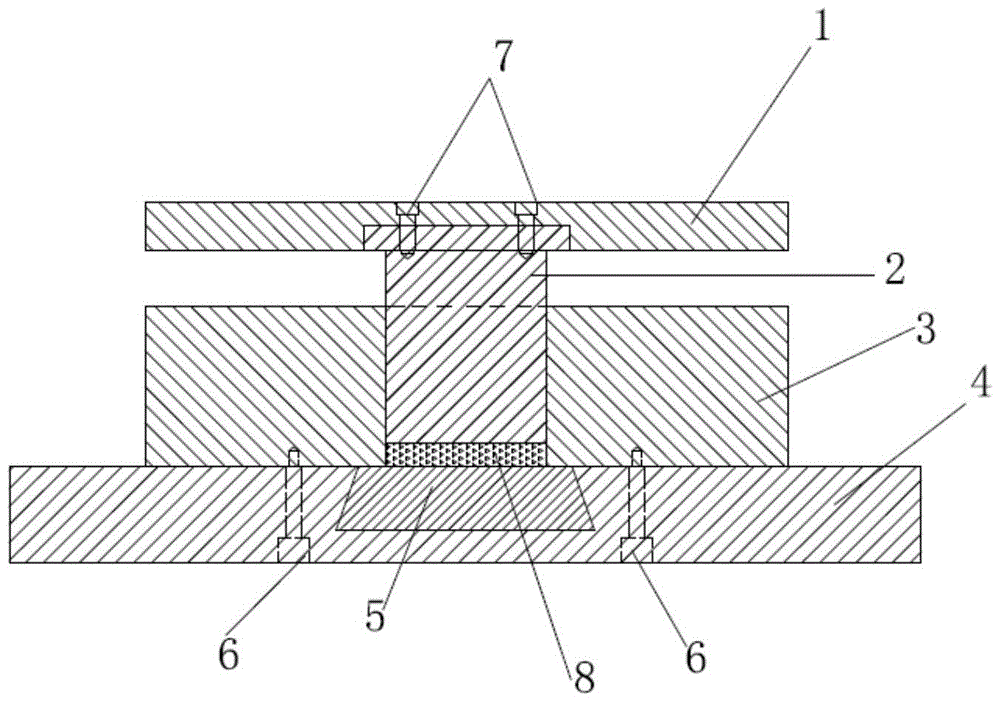

[0024] according to figure 1 , figure 2 , image 3 As shown, the mold of the ultra-high pressure hydraulic pressure high-density fly ash, slag and spent catalyst module of this embodiment consists of an upper pressure module 1, an upper mold punch 2, an intermediate module 3, a lower pressure base 4, and a slider 5. Big hexagonal screw 6, small hexagonal screw 7 forms. The upper pressure-bearing module 1 and the upper die punch 2 can be fixedly connected directly by the small hexagonal screw 7, or the upper pressure-bearing module 1 that is in contact with the upper die punch 2 can be opened to match the top shape of the upper die punch 2 and the shape of the upper die punch 2. The size matches the groove, and then press the upper die punch 2 into the groove, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com