Microwave-based drying device and drying method for treating reactor core waste water

A drying device and wastewater treatment technology, applied in nuclear engineering, radioactive purification, etc., can solve the problems of minimization of non-compliant radioactive waste, increase of disposal cost, and increase of disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

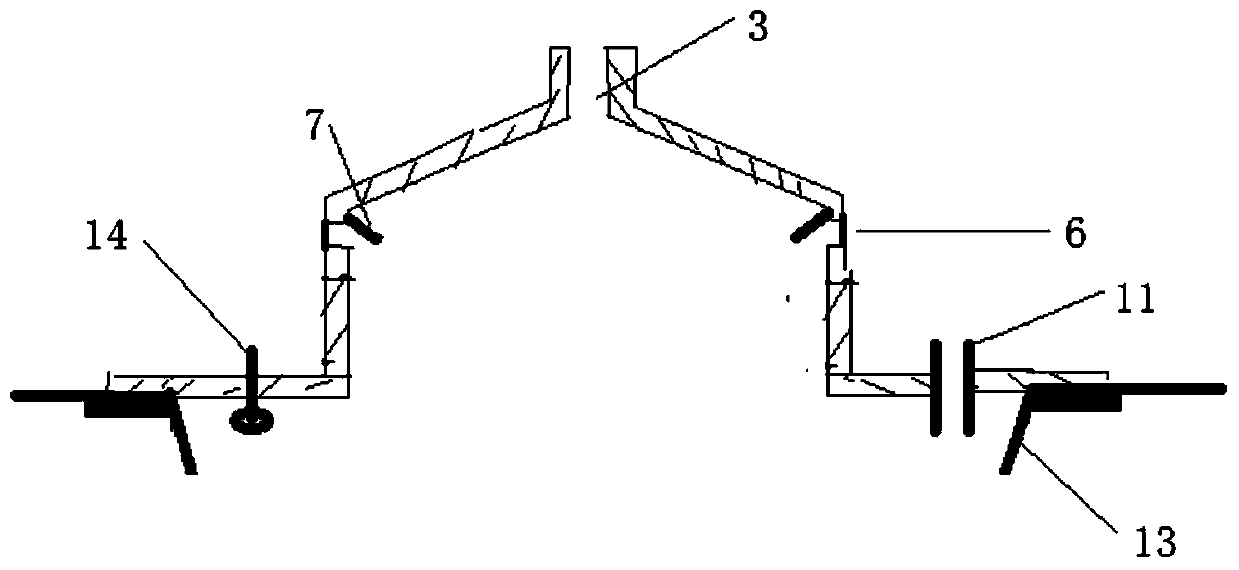

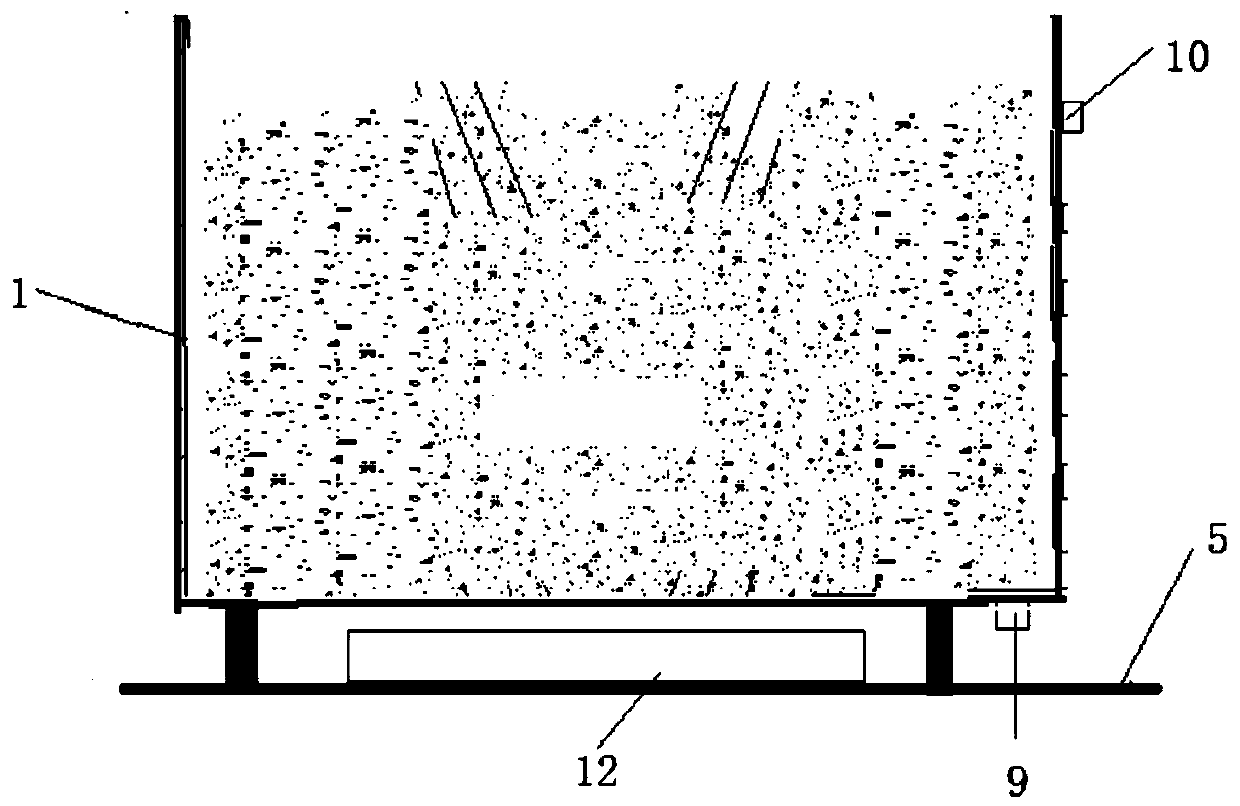

[0035] like Figure 1 to Figure 3 As shown, a microwave-based drying device for core wastewater treatment includes a drying area and a microwave feeding area, wherein the drying area is used to hold the core wastewater to be treated, and the drying area can treat the core wastewater For heating, the microwave feeding area is located above the drying area, and microwaves are fed from the side of the microwave feeding area and irradiate the liquid surface of the core wastewater to heat the core wastewater in a non-contact manner. At the same time, the microwave feeding area above A steam outlet 3 is provided, and the water vapor evaporated from the core wastewater is discharged through the steam outlet 3.

[0036] Specifically, the drying area is a drying barrel 1 , an electromagnetic induction heater 12 is provided under the drying barrel 1 for heating, and a thermal insulation shell 4 is arranged around the drying barrel 1 . At the same time, the drying barrel 1 is set as an ...

Embodiment 2

[0042] The same part of this embodiment and Embodiment 1 will not be described again, the difference is:

[0043] Place the drying barrel 1 on the base 5 at one station, transport the drying barrel 1 to the bottom of the microwave feeding barrel 2 (there is a sealing gasket 13 under the microwave feeding barrel 2) through a suitable transmission structure, and the base 5 rises, The drying barrel 1 is combined with the microwave feeding barrel 2, and the sealing gasket 13 is embedded in the drying barrel 1 to realize sealing.

[0044] Turn on the microwave, high-power exhaust fan and electromagnetic induction heater 12 according to the work flow. During the work process, the solution liquid level measured by the non-contact microwave liquid level gauge 14 maintains the liquid in the drying barrel 1 during the work process through the liquid replenishment port 11. The level is maintained at the set value liquid level, and the electromagnetic induction heater 12 is controlled acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com