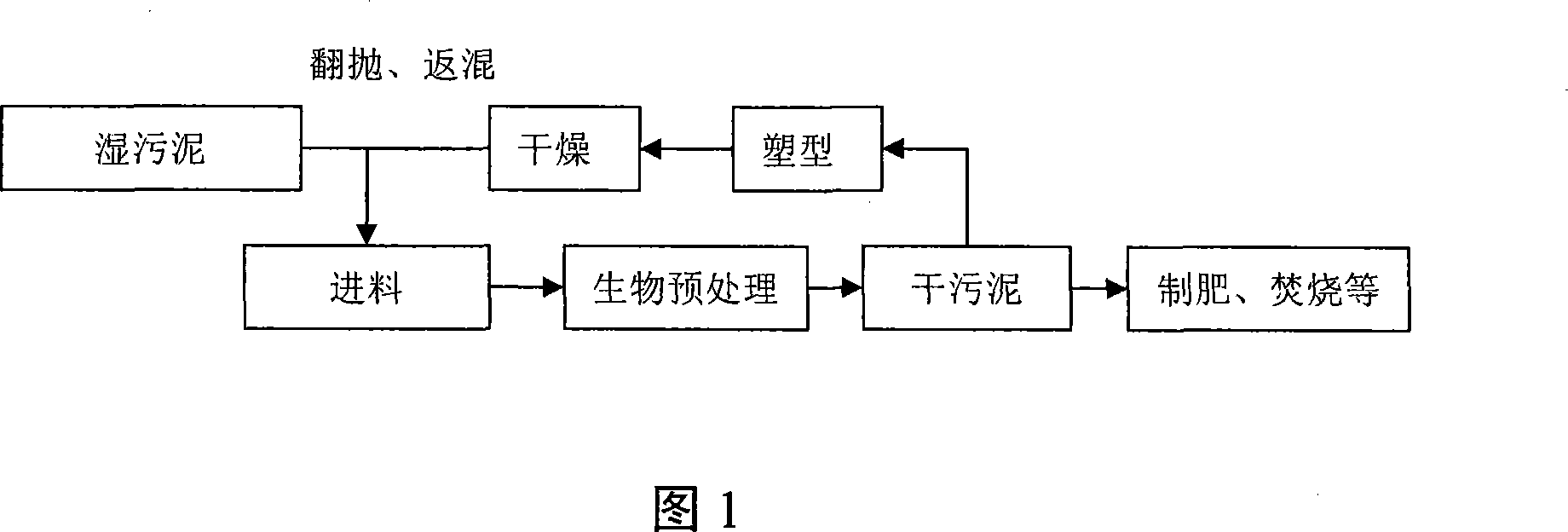

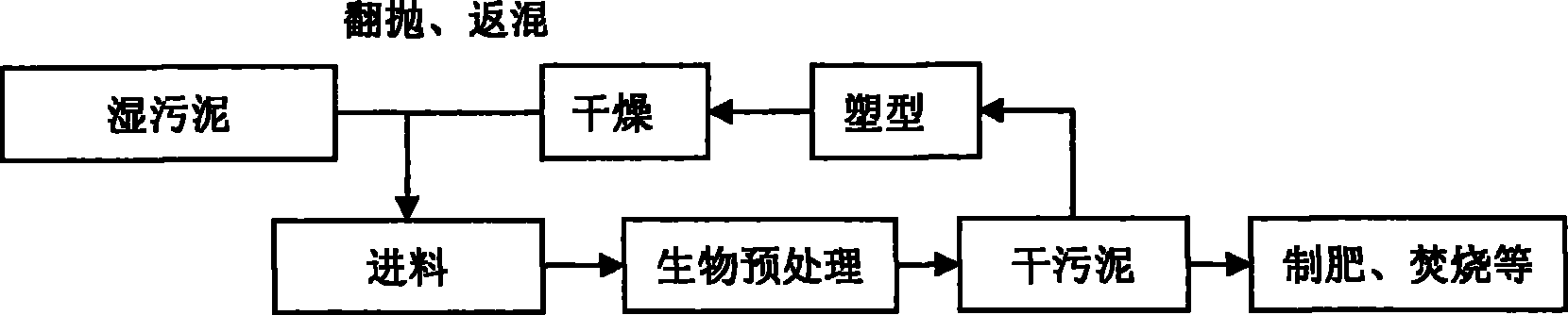

Back mixing method for pretreatment of sludge

A biological pretreatment and sludge technology, applied in the fields of biological sludge pretreatment, backmixing and sludge treatment, can solve the problems of increasing treatment cost, prolonging treatment period, inconvenient production, etc. The effect of processing cycle time and processing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Take 200.0kg of wet sludge from a sewage treatment plant, with a moisture content of 70% and an organic matter content of 50%, for the dry sludge back-mixing biological pretreatment test. Prepare 56.0 kg of back-mixed dry sludge of A and B, with a water content of 20%, and the mass ratio of A and B is 9:1, wherein A is 50.4 kg and B is 5.6 kg. After the dry and wet materials are turned over and mixed, they are stacked in strips in the test site, the moisture content is adjusted to 60%, and the total weight is 256.0kg. During the biological pretreatment process, forced ventilation is used to supply oxygen, and the wind pressure is 1.0kPa / m 2 , Turn over and throw once every 3 days, the temperature of the sludge heap will reach above 60°C after 35 hours, keep it for 89 hours, then start to cool down, and end after 14 days. The final product of sludge is in aggregate structure, with a moisture content of 35.5%, organic matter degradation of 40%, and sludge weight reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com