Distributed low-temperature plasma tubular accelerator straw fertilizer manufacturing machine

A technology of plasma tube and high-temperature plasma, which is applied in the field of ion tube accelerator straw fertilizer making machine, can solve the problems of flue gas emission failing to form resource utilization, lack of straw, and small processing capacity, etc., and achieve soluble nitrogen and other soluble The fertilizer and water dissolve and react quickly and fully, eliminating the effect of continuous cropping and reducing the amount of garbage ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to illustrate the embodiments of the present invention more clearly, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other accompanying drawings based on these drawings and obtain other implementations.

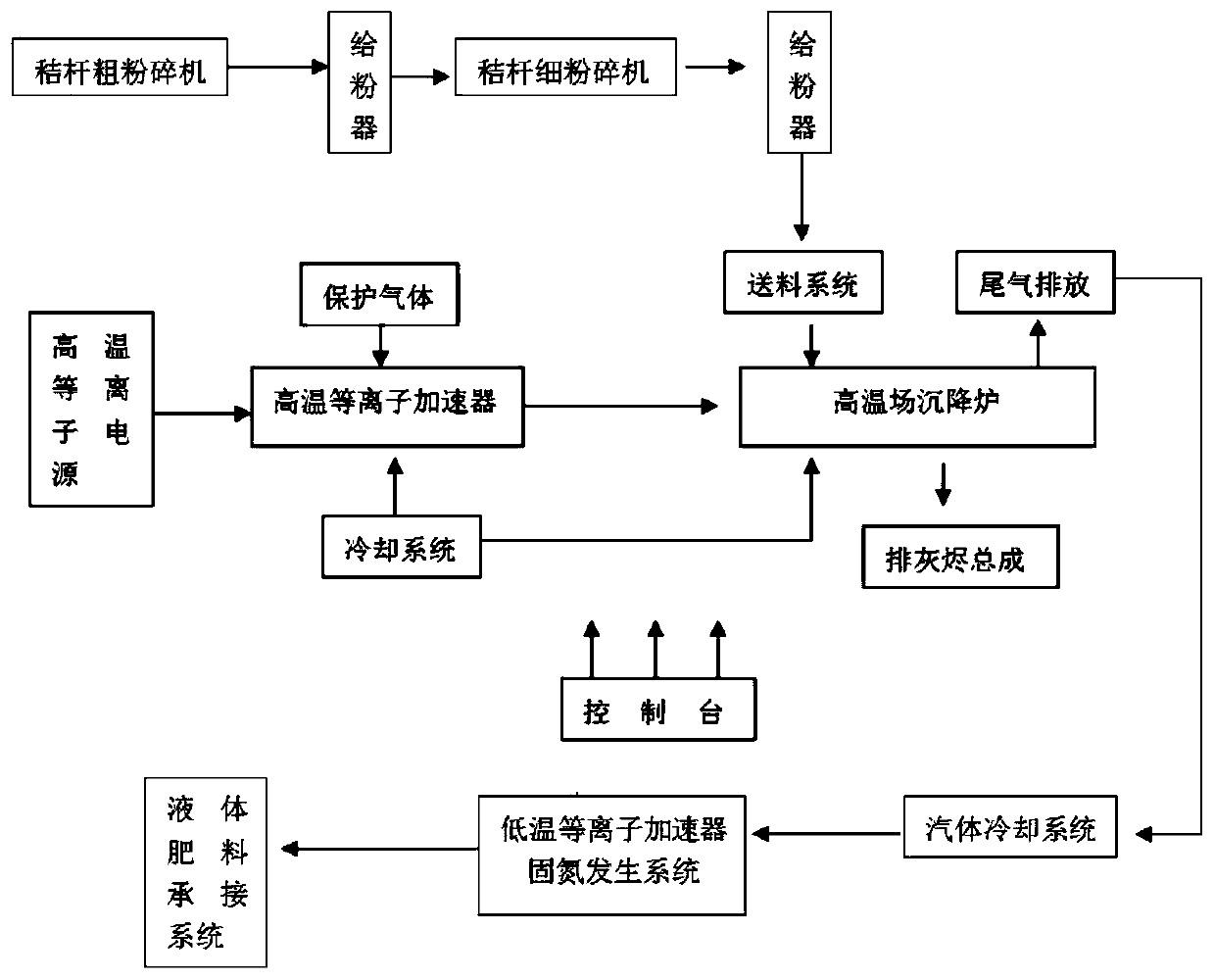

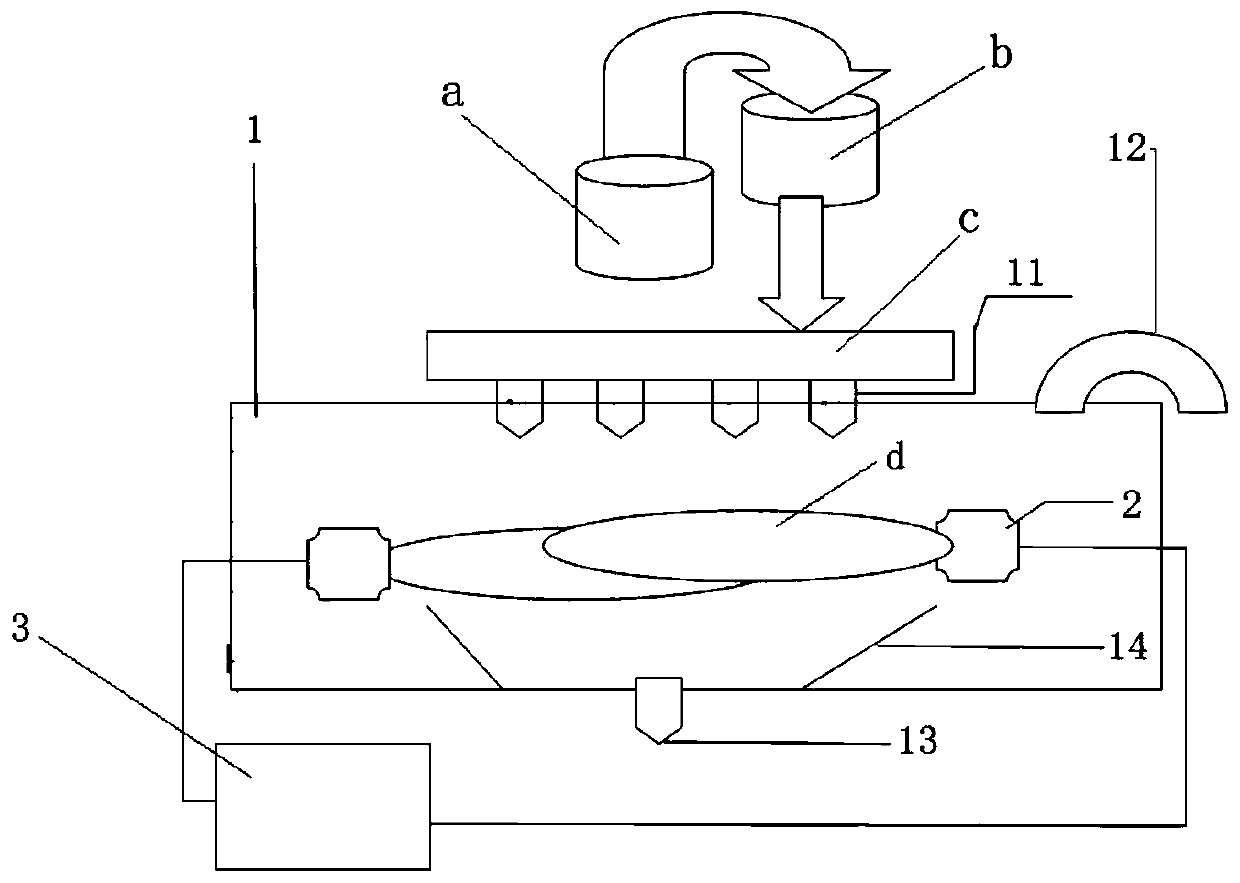

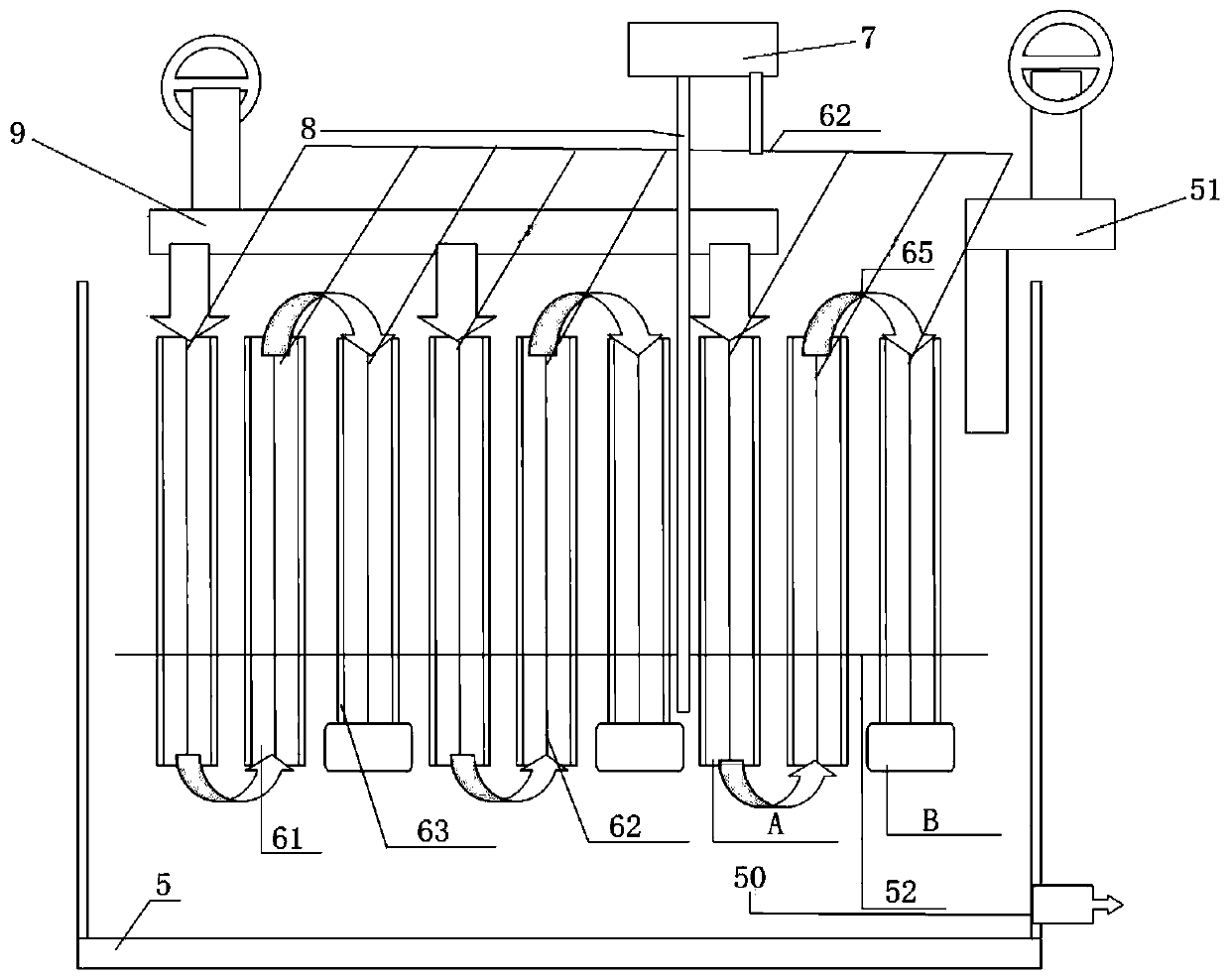

[0042] Such as Figure 1-3 As shown, the distributed low-temperature plasma tube accelerator straw fertilizer machine of the embodiment of the present invention includes a straw coarse pulverizer, a straw fine pulverizer, a high-temperature field sedimentation furnace, a high-temperature plasma accelerator, a high-temperature plasma arc power supply, a closed water tank, and a distributed Type low temperature plasma tube accelerator, plasma power supply.

[0043] Specifically, the straw coarse grinder performs basic prelim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com