Air intake method for furnace of waste incineration boiler and waste incineration boiler equipment

A technology of waste incineration and boiler furnace, which is applied in combustion methods, combustion equipment, fluidized bed combustion equipment, etc., can solve the problems of not reaching the decomposition temperature of dioxin, wear of boiler parts, shortening of service life, etc. Effects of pollution, low production efficiency, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

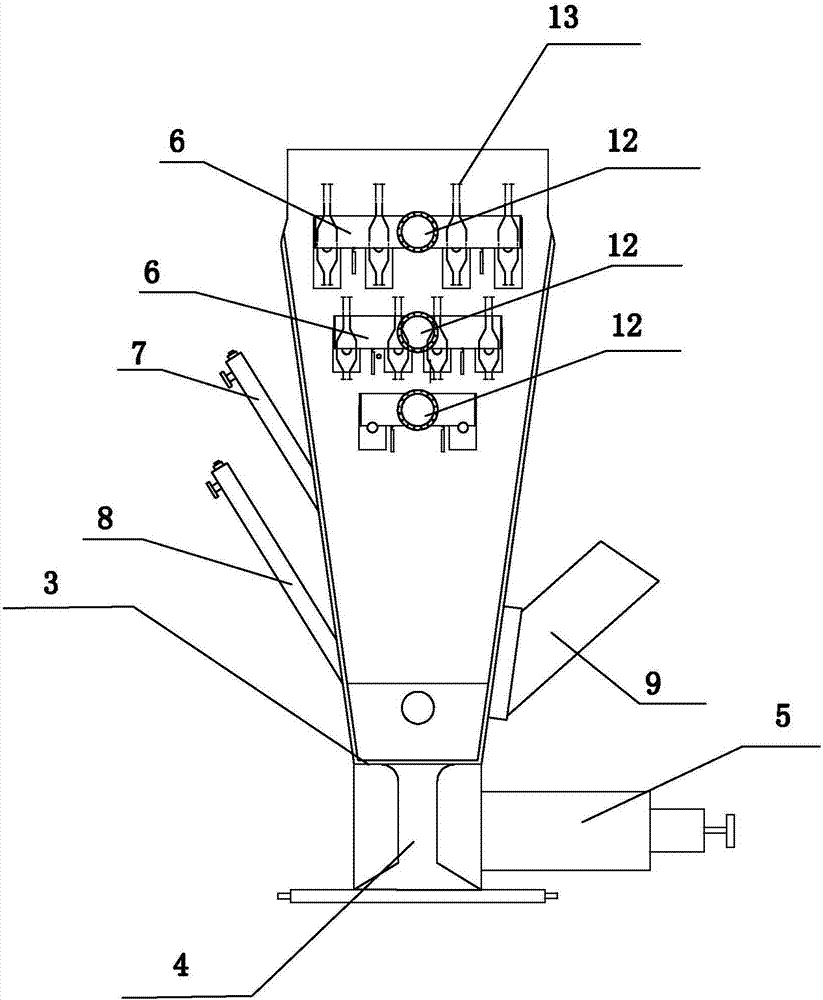

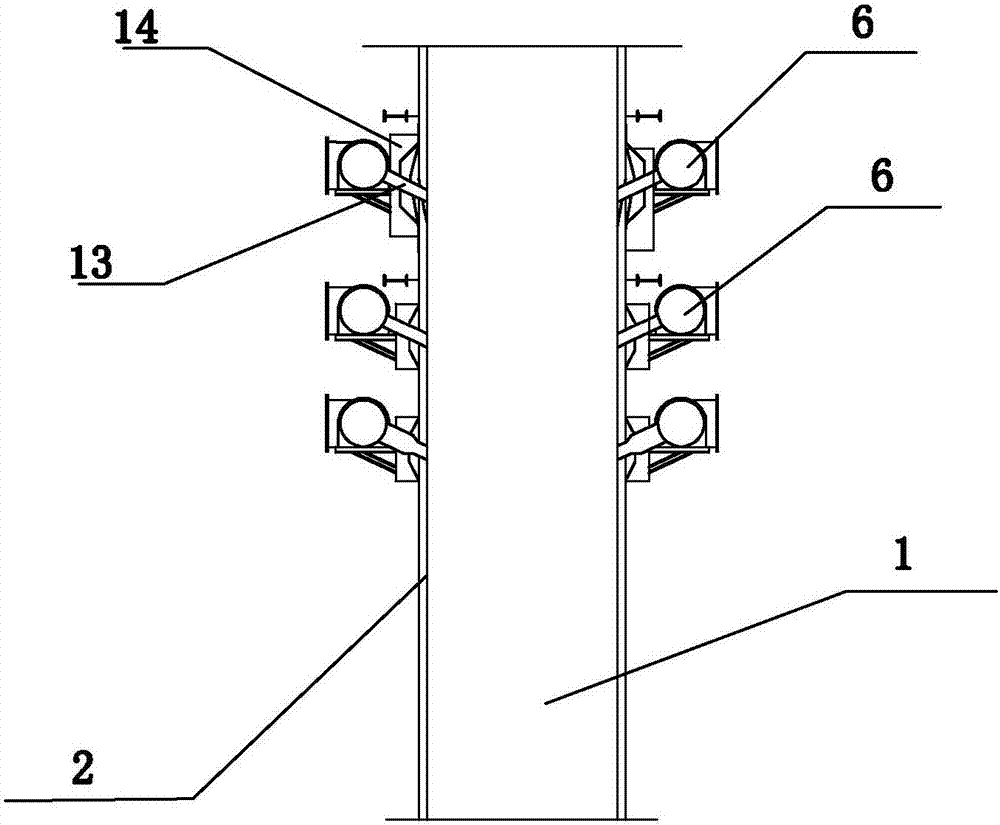

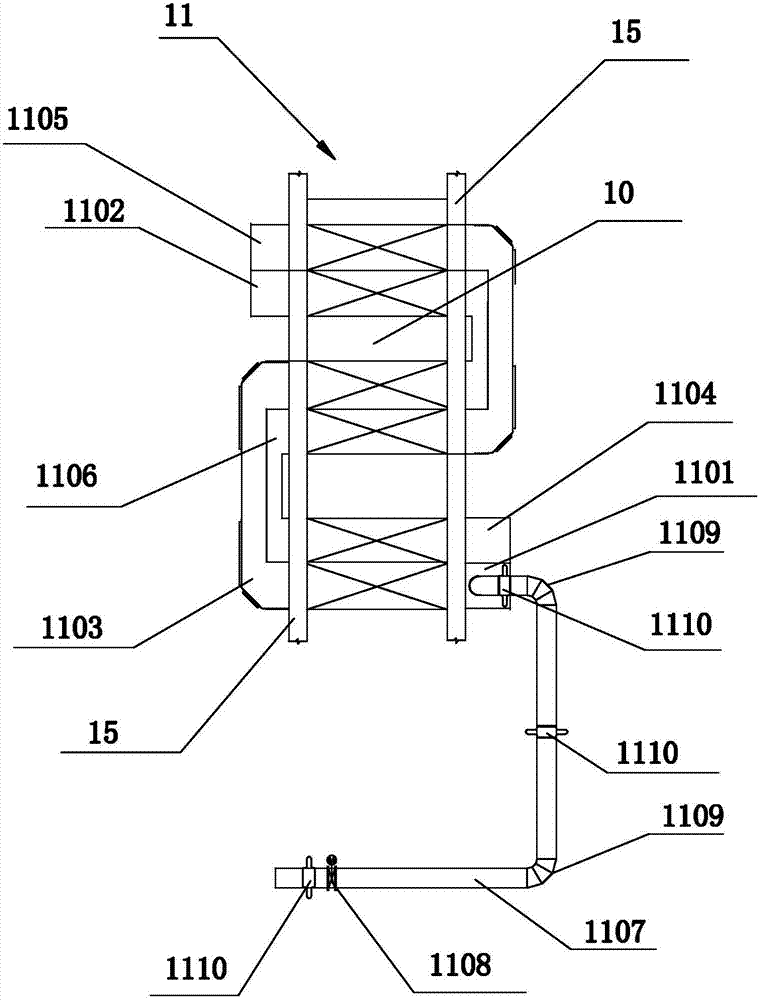

[0036] Such as Figure 1 to Figure 4 As shown, the intake method of furnace 1 of 500t / d different gravity circulating fluidized bed waste incineration boiler, said waste incineration boiler includes furnace wall 2, furnace 1, furnace wall air inlet pipe 6, air distribution plate 3, and air chamber 4 , the air inlet 5 of the air chamber, the flue 10 and the air preheating device 11; side, the air chamber 4 is below the air distribution plate 3; the air preheating device 11 is arranged at the lower part of the flue 10, and the air preheating device 11 includes a preheating pipe, an air inlet and an air outlet; the air intake method includes The air enters the primary air intake at the lower part of the furnace 1 from the air outlet of the preheating pipe to the air inlet 5 of the air chamber, the air chamber 4 and the air distribution plate 3, and the air enters the furnace 1 from the air outlet of the preheating pipe through the air inlet pipe 6 of the furnace wall The seconda...

Embodiment 2

[0051] The DCS distributed control system is disconnected from the electric circular damper 1108, and the temperature of the air chamber 4 can be manually controlled through the electric circular damper 1108.

[0052] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com