Sludge drying device

A sludge drying and feeding hopper technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc., can solve the problem of effectively reducing the moisture content of sludge, Sludge cannot be further utilized, and it is difficult to remove sludge moisture, etc., to improve heat transfer and drying effects, facilitate storage and transportation, and avoid sludge stagnation areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

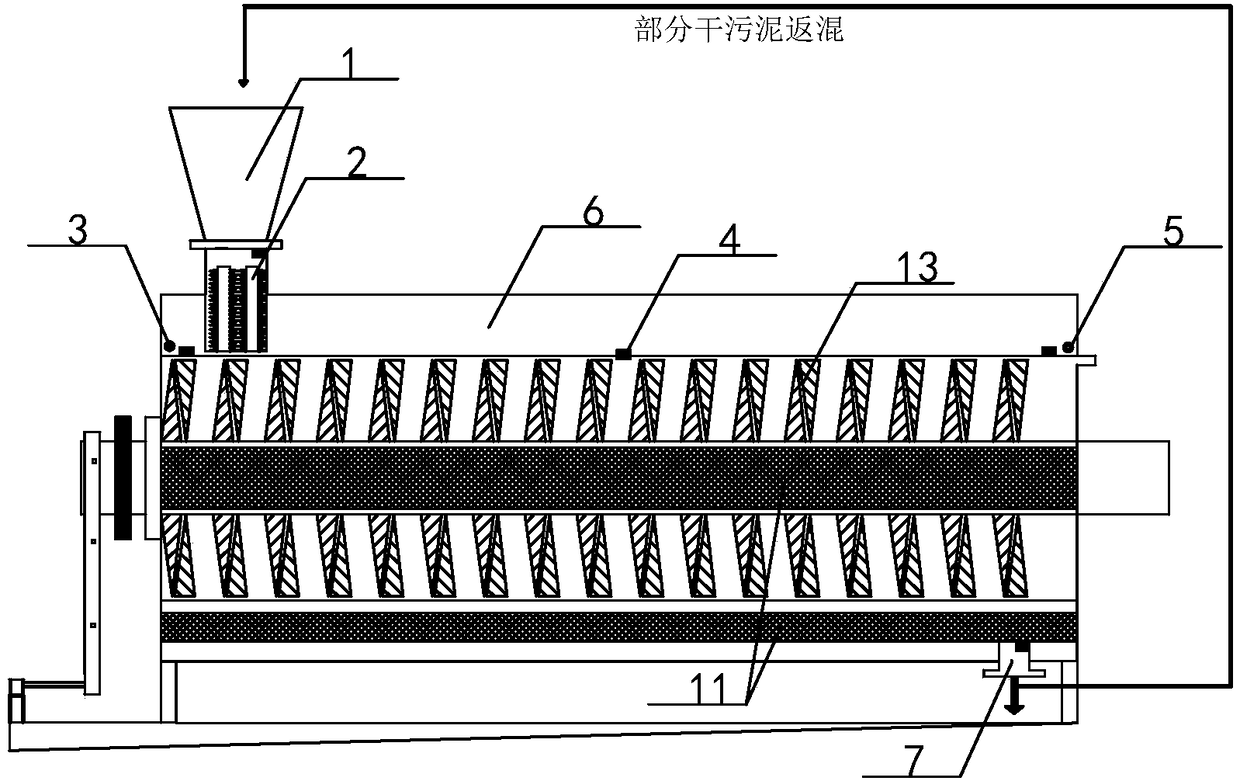

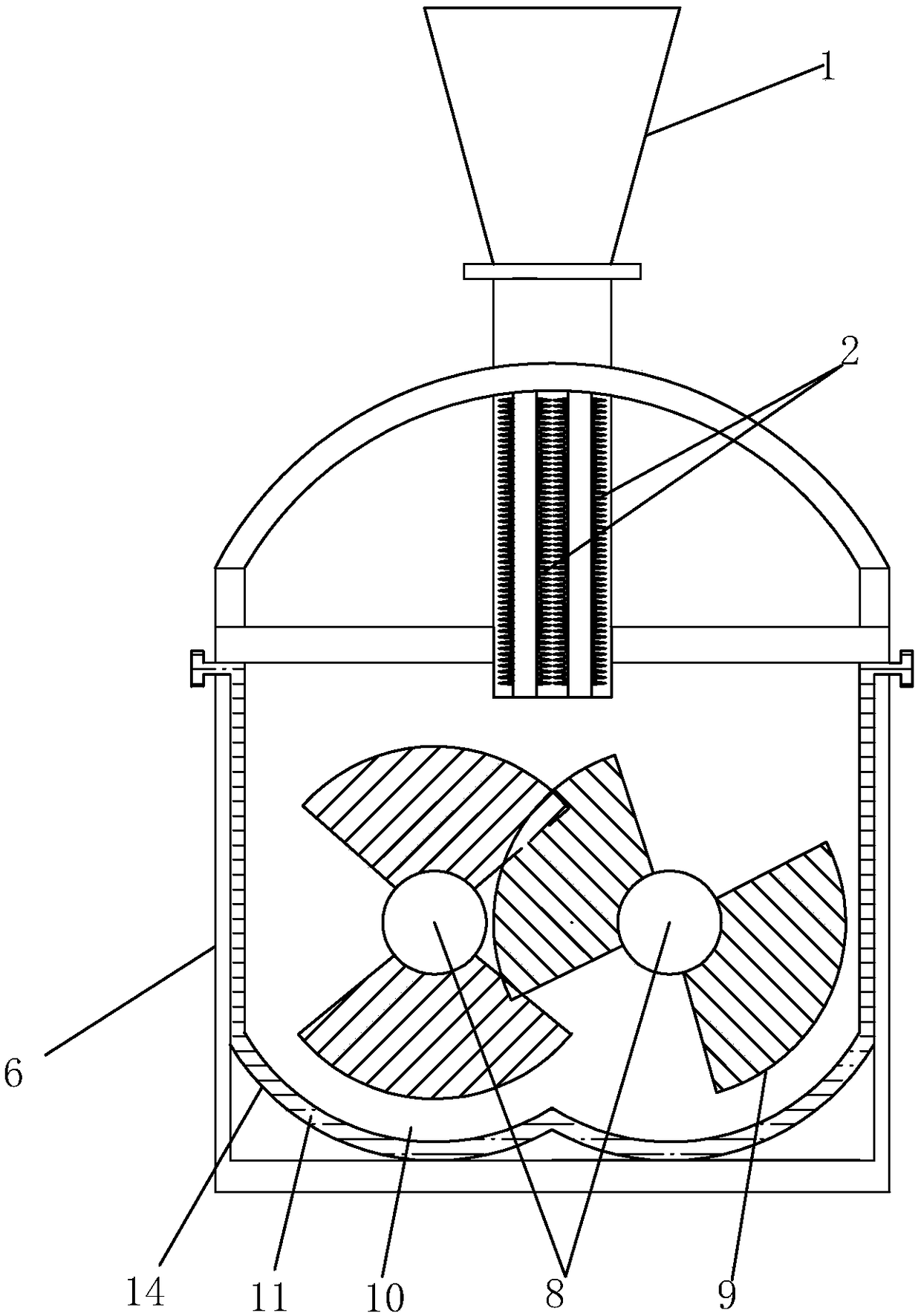

[0030] refer to figure 1 , figure 2 , a sludge drying device, including a box body 6, a feed hopper 1, a feed screw group 2, a discharge port 7, and a push screw group 13, etc. The feed hopper 1 is fixed on the box body 6, and is located at the top of one side of the box body 6, and the discharge port 7 is located at the bottom of the other side of the box body.

[0031] The feeding screw group 2 is installed at the bottom of the feeding hopper 1 to assist feeding, and it includes two feeding screws, and the number of feeding screws is not unique, and can also be one. Each feeding screw is provided with a rotating shaft 8 and several helical sheets 9 , and the several helical sheets 9 are fixed on the rotating shaft 8 . Two feeding screws are arranged in parallel at the bottom of the feeding hopper 1, and the rotation of the rotating shaft 8 is controlled to drive the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com