An integrated method for the pretreatment of high-concentration printing and dyeing wastewater based on tubular membranes

A printing and dyeing wastewater and integrated method technology, applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low COD removal rate, difficult removal of polymer refractory organic matter, etc. Achieve the effects of enhanced biodegradability, high permeate flux, and large flow channel in the inner cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments.

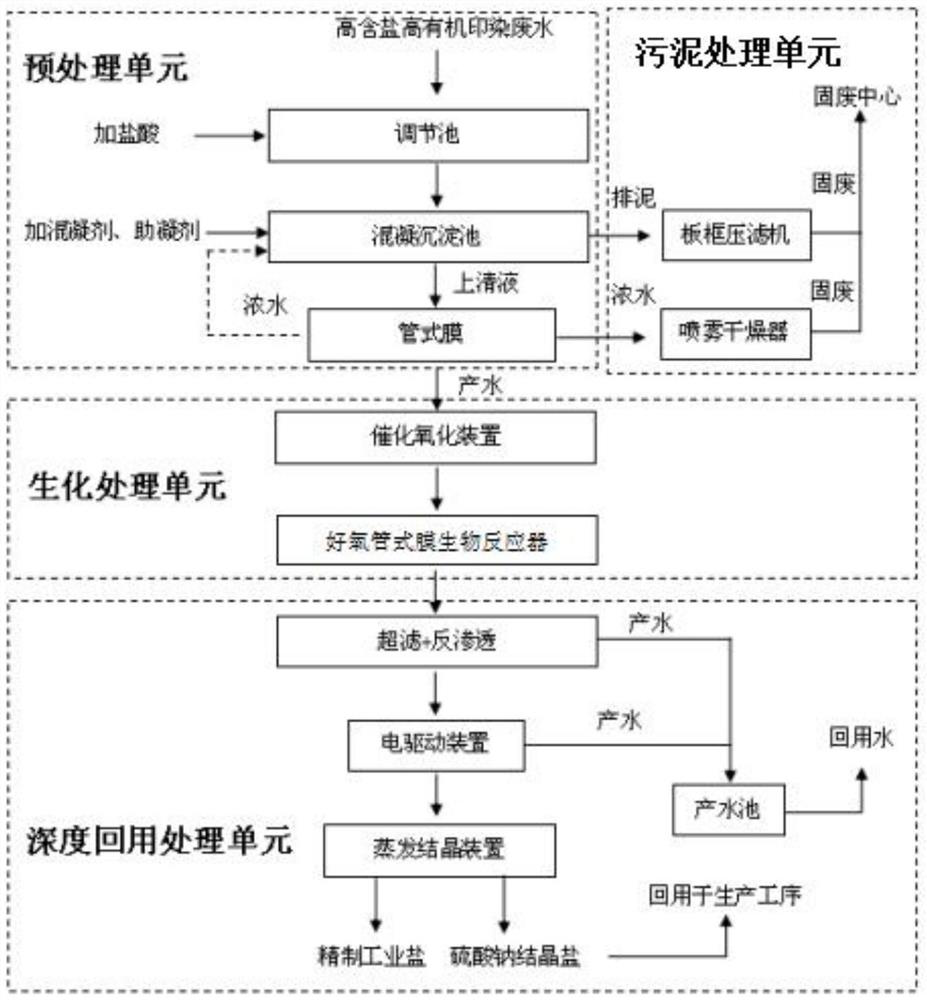

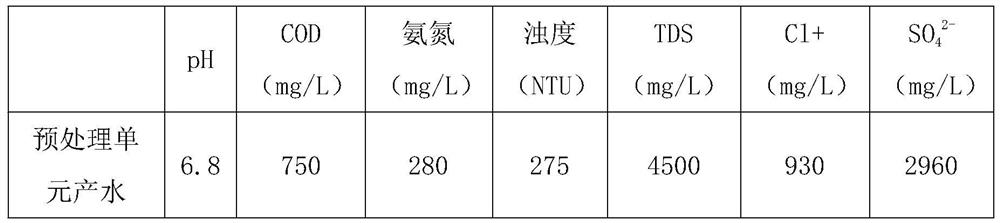

[0025] refer to figure 1 , an integrated method for pretreatment of high-concentration printing and dyeing wastewater based on tubular membranes, including a pretreatment unit, a biochemical treatment unit, a deep reuse treatment unit, and a sludge treatment unit, the pretreatment unit including a regulating tank, coagulation and sedimentation Pool and tubular membrane, the biochemical treatment unit includes a catalytic oxidation device and an aerobic tubular membrane bioreactor, and the deep reuse treatment unit includes ultrafiltration, reverse osmosis, electric drive device, evaporation crystallization device and water production pool, The sludge treatment unit includes a plate and frame filter press and a spray dryer.

[0026] Among them: the tubular membrane has the dual functions of removing insoluble and soluble macromolecular organic matter and desalination. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com