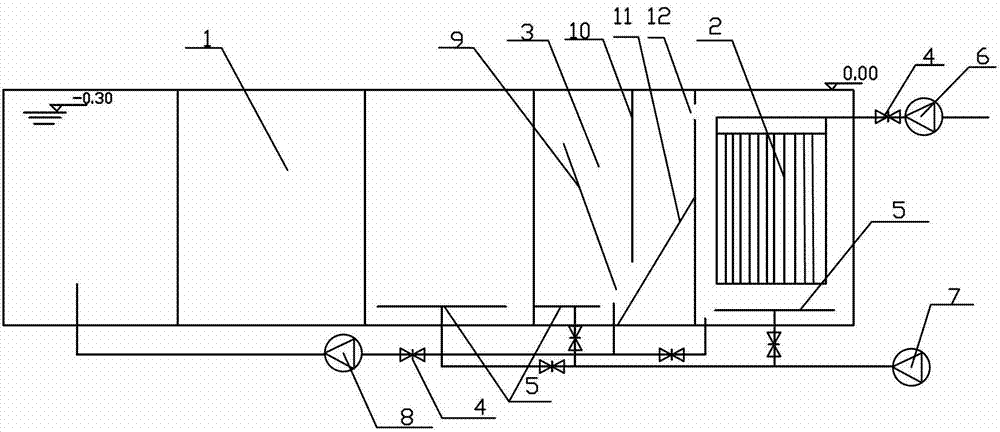

Membrane biological reaction system

A membrane biological reaction and biological treatment technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of insufficient spare space, inconvenience, and insufficient and effective utilization. , to achieve the effect of low construction difficulty, small footprint and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

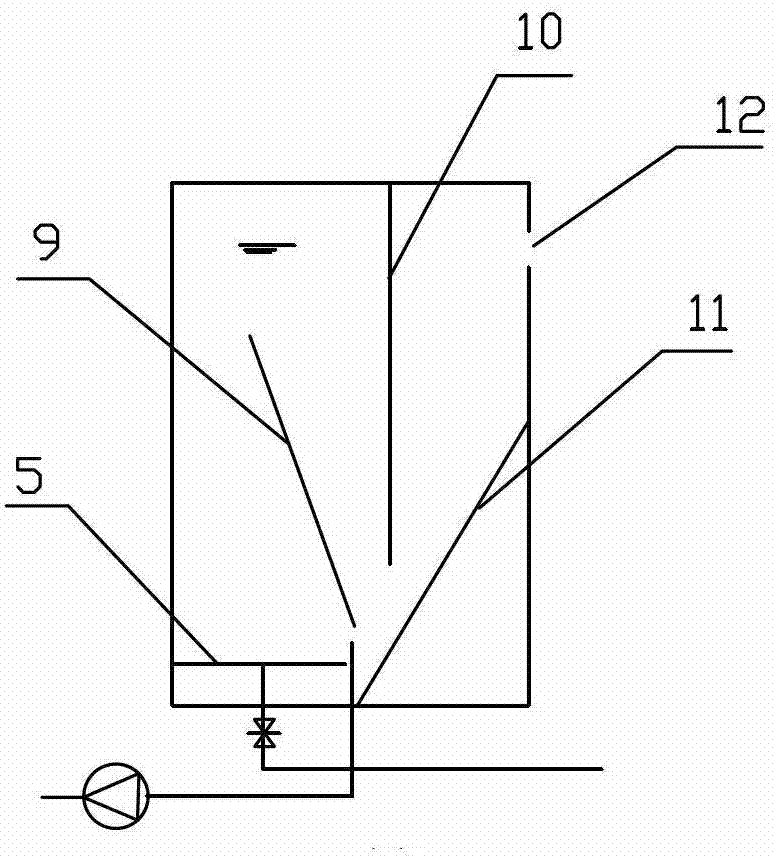

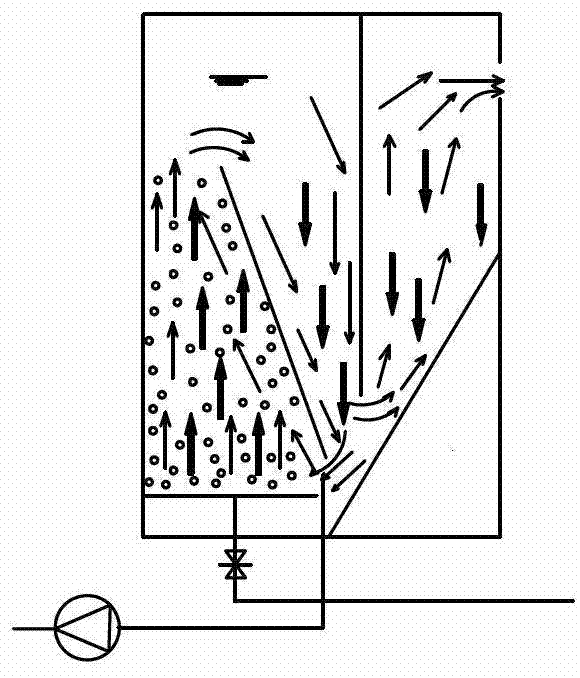

Method used

Image

Examples

Embodiment 1

[0029]Example 1: Sewage first enters the biological treatment unit. The activated sludge concentration of the biological treatment unit is about 7000mg / L, and the residence time is 16h. The effluent of the biological treatment unit enters the mud-water separation device. In the area formed by the first diversion wall, the second diversion wall and the third diversion wall, the activated sludge with good settling performance descends to the lower ends of the first diversion wall, the second diversion wall and the third diversion wall, And through the aeration of the aeration device, it enters the aeration area and participates in the circulation. The activated sludge from the mud-water separation device is returned to the biological treatment unit through the submersible pump, and pollutants such as organic matter and nitrogen and phosphorus are removed in the biological treatment unit and the mud-water separation device. The activated sludge with poor settling performance ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com