Plasma melting and cracking furnace

A plasma and cracking furnace technology, applied in the mechanical field, can solve problems such as cutting garbage or melting and cracking a small area, spreading infection, affecting soil and water quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings,

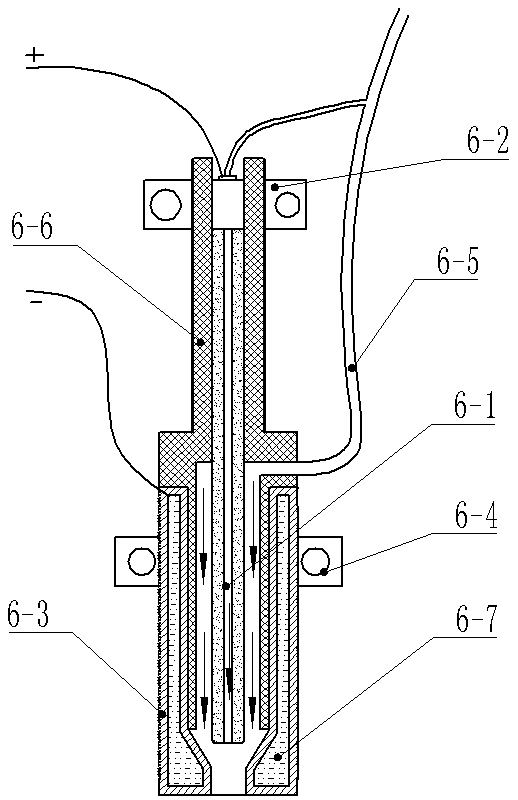

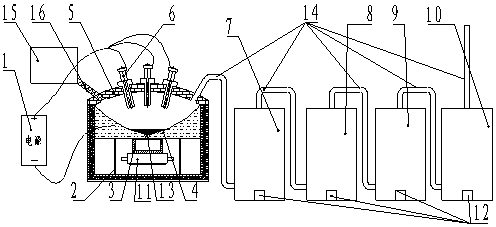

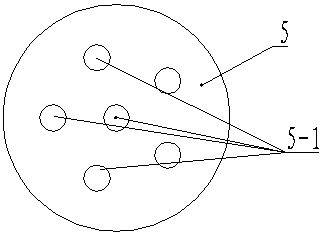

[0020] A plasma melting and cracking furnace, comprising a power source (1), a support (2), a material receiving die (3), a crucible (4), a furnace cover (5), a plasma torch generating device (6), and a heat exchanger (7) , a first-stage sedimentation purification chamber (8), a second-stage electrostatic purification chamber (9), a third-stage filtering purification chamber (10) and a high temperature resistant belt conveyor (11), characterized in that: the furnace cover (5) ) is provided with an exhaust port, a screw feeder (16) and a plurality of installation holes (5-1) for the plasma torch generating device, and the exhaust port is connected by an exhaust pipe (14); the screw feeder (16) is connected A hopper (15); a plasma torch generating device (6) is fixed in the plasma torch generating device mounting hole (5-1); one output end of the power supply (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com