Composition containing bismaleimide oligomer and preparing method thereof

A technology of bismaleimide and maleimide monomers is applied in the field of compositions containing high-purity bismaleimide oligomers, and can solve the problems of high hygroscopicity, complex modification and structural variability , high manufacturing costs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

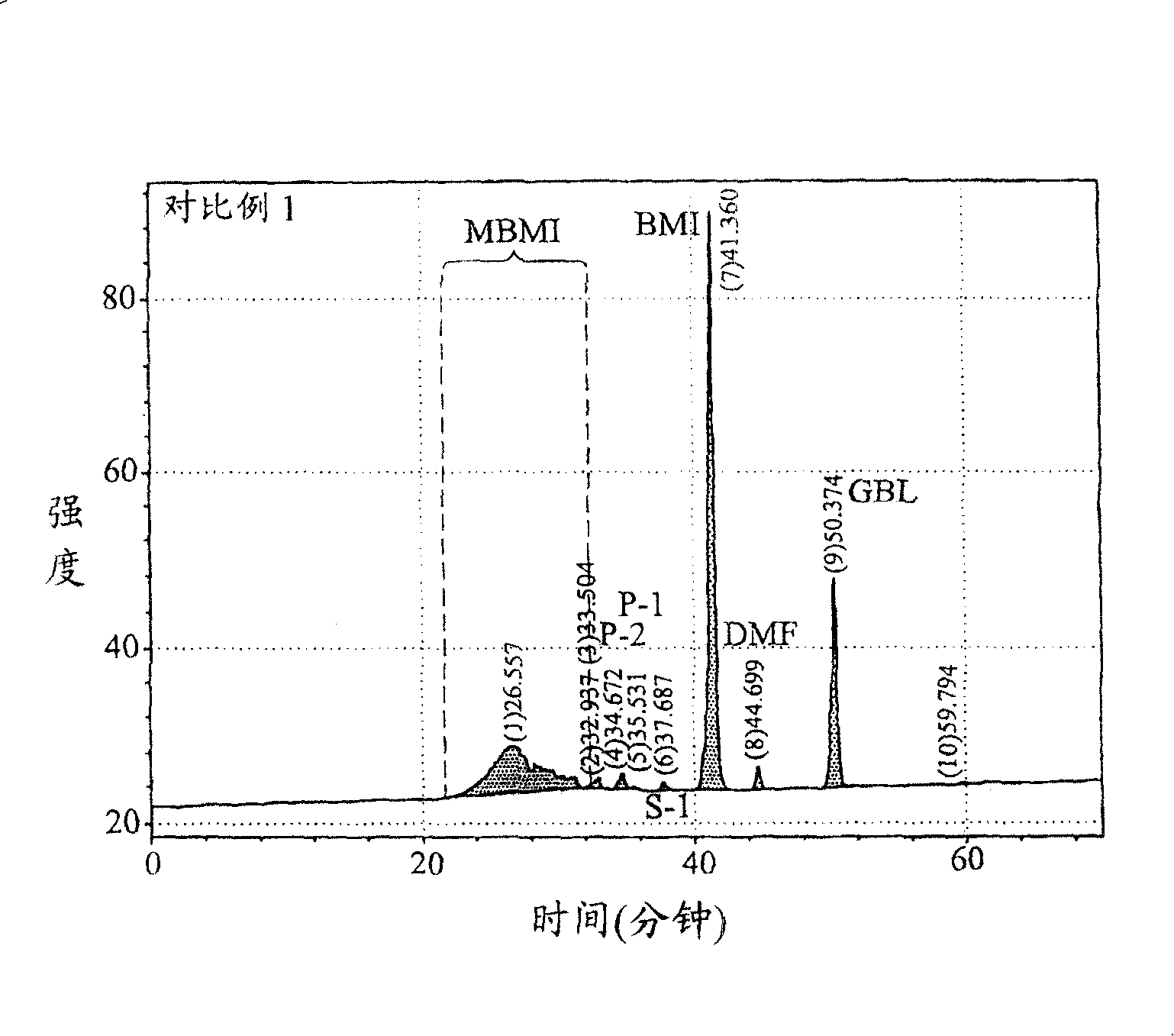

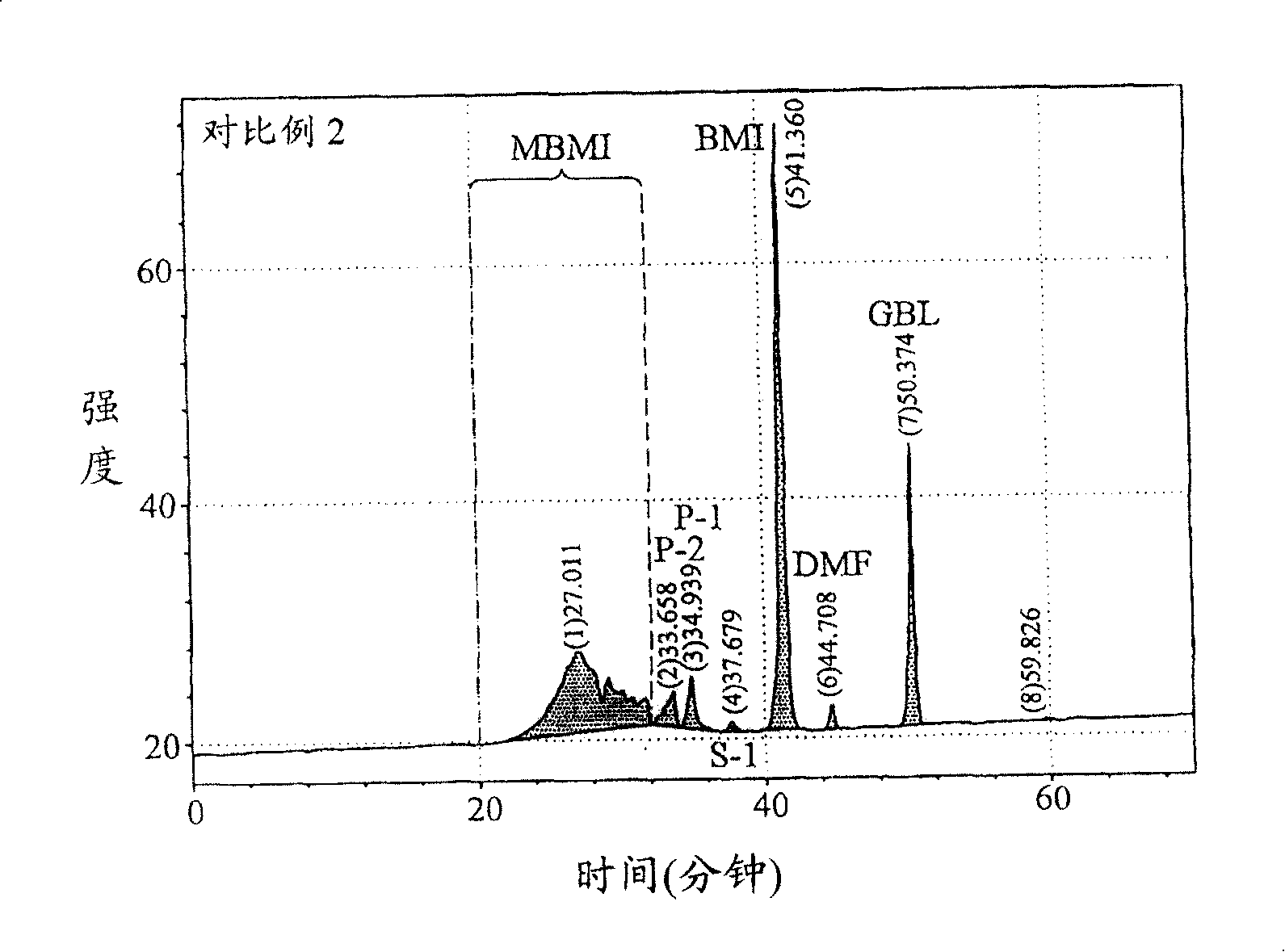

Examples

preparation example Construction

[0015] The present invention provides a high-purity multifunctional dimaleimide oligomer with good solvent solubility and compatibility with resins and a high-purity multifunctional dimaleimide oligomer with a hyper branch architecture and good reactivity, and its containing The manner in which the composition is prepared. The preparation method of the composition containing bismaleimide oligomer comprises the following steps:

[0016] First, the bismaleimide monomer is dissolved in a solvent, and then, barbituric acid is added in batches in the solvent containing the bismaleimide monomer, wherein each addition of barbituric acid The molar ratio to the bismaleimide monomer is less than 0.2. Reaction formula (I) is an example of the procedure for preparing and synthesizing the high-purity polyfunctional bismaleimide oligomer of the present invention. In this embodiment, barbituric acid or its derivatives are gradually added to the bismaleimide / In the solution of the solvent...

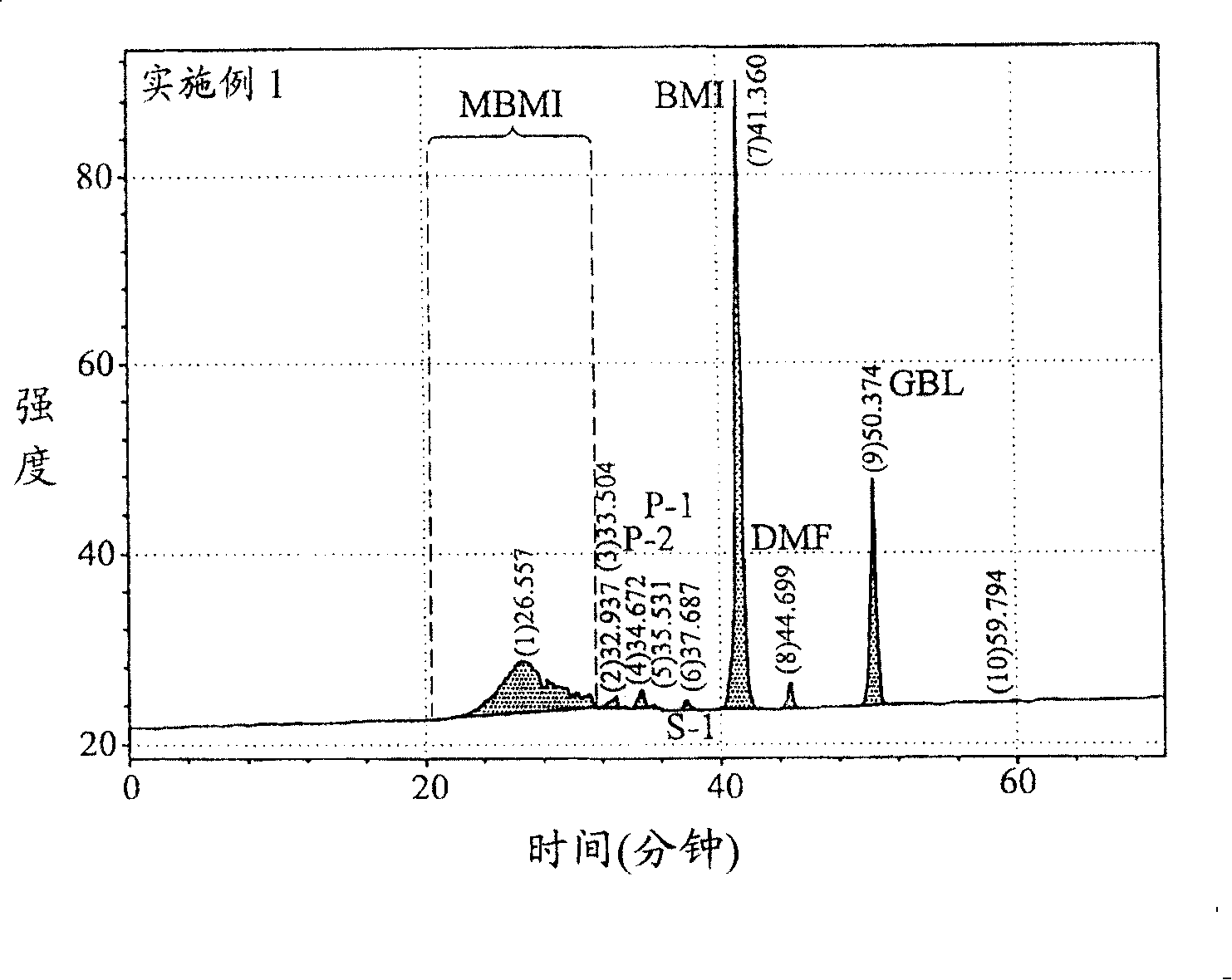

Embodiment 1

[0044] Take 20.0002 grams of bismaleimide monomer granules or powder and place it in a 250ml round-bottomed three-necked bottle, add 94.3022 grams of γ-butyrolactone (γ-Butyrolactone) solvent, and heat to 130°C and stir thoroughly to make Dimaleimide monomer can be completely dissolved in γ-Butyrolactone (γ-Butyrolactone) solvent. Weigh 3.5752 grams of barbituric acid powder, divide it into 8 equal parts, add the material every 30 minutes, and gradually add it to 130 ℃ dimaleimide / γ-butyrolactone (γ-butyrolactone) in batches and sections. In the solution of Butyrolactone), fully stir to carry out the polymerization reaction of bismaleimide, after the barbituric acid is added completely, continue to act and react for 6 hours, the molar concentration of bismaleimide and barbituric acid The ratio is about 2:1.

Embodiment 2

[0046] Take 19.9995 grams of bismaleimide monomer granules or powder and place it in a 250ml round-bottomed three-necked bottle, add 108.6008 grams of γ-butyrolactone (γ-Butyrolactone) solvent, and heat to 130°C and stir thoroughly to make Dimaleimide monomer can be completely dissolved in γ-Butyrolactone (γ-Butyrolactone) solvent. Weigh 7.1483 grams of barbituric acid powder, divide it into 16 equal parts to add material, add material once every 15 minutes, and gradually add in 130 ℃ dimaleimide / γ-butyrolactone (γ-butyrolactone) in batches and sections In the solution of Butyrolactone), fully stir to carry out the polymerization reaction of bismaleimide, after the barbituric acid is added completely, continue to act and react for 6 hours, the molar concentration of bismaleimide and barbituric acid The ratio is about 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com