Method and device for pretreatment of high-temperature liquid water of cellulosic biomass

A high-temperature liquid water and pretreatment device technology, which is applied in sugar production, sugar production, food science, etc., can solve the problems of long distance for industrial application, high equipment requirements, and many by-products, so as to avoid further Degradation, improvement of hydrolysis effect, and efficient hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

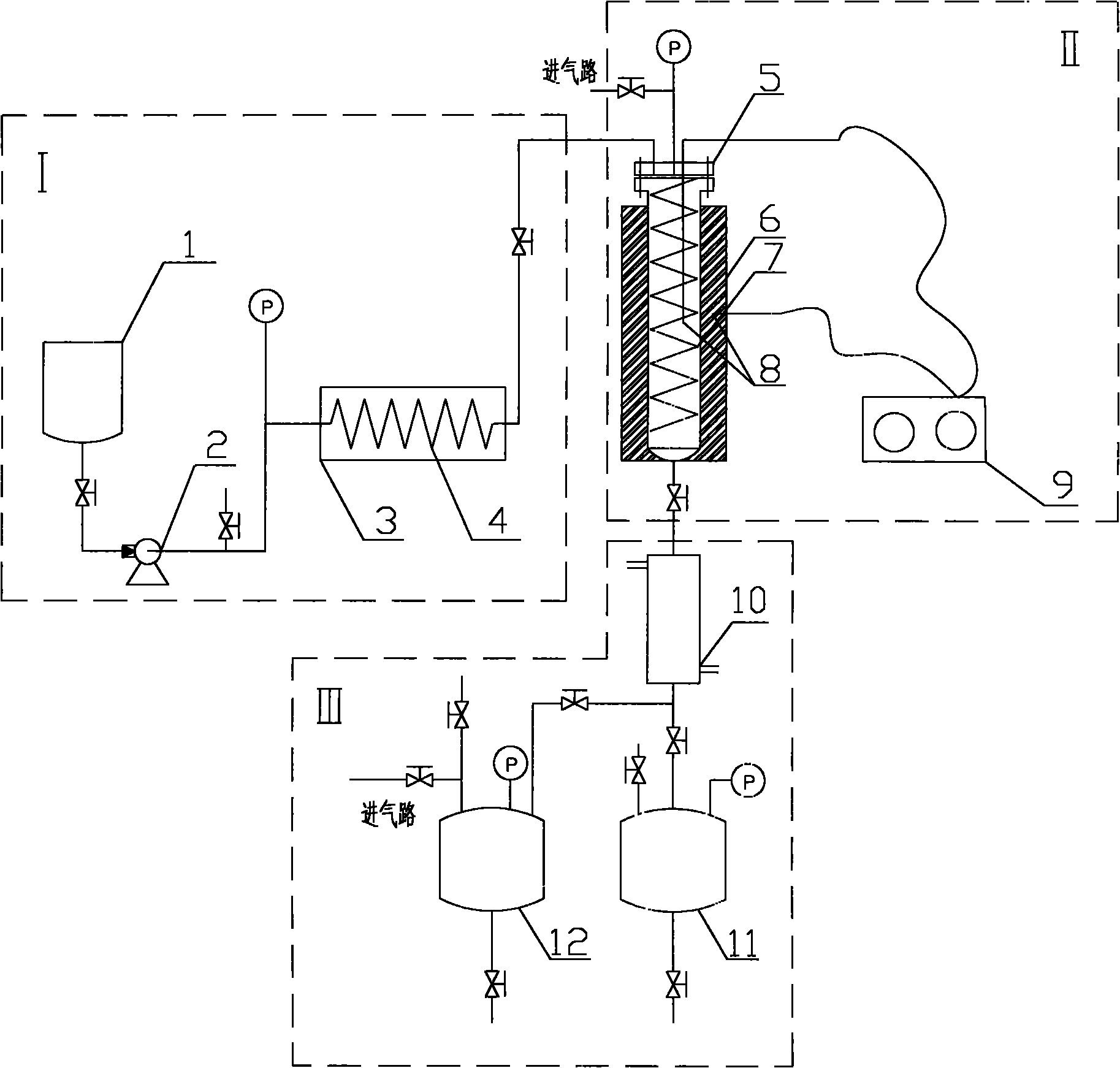

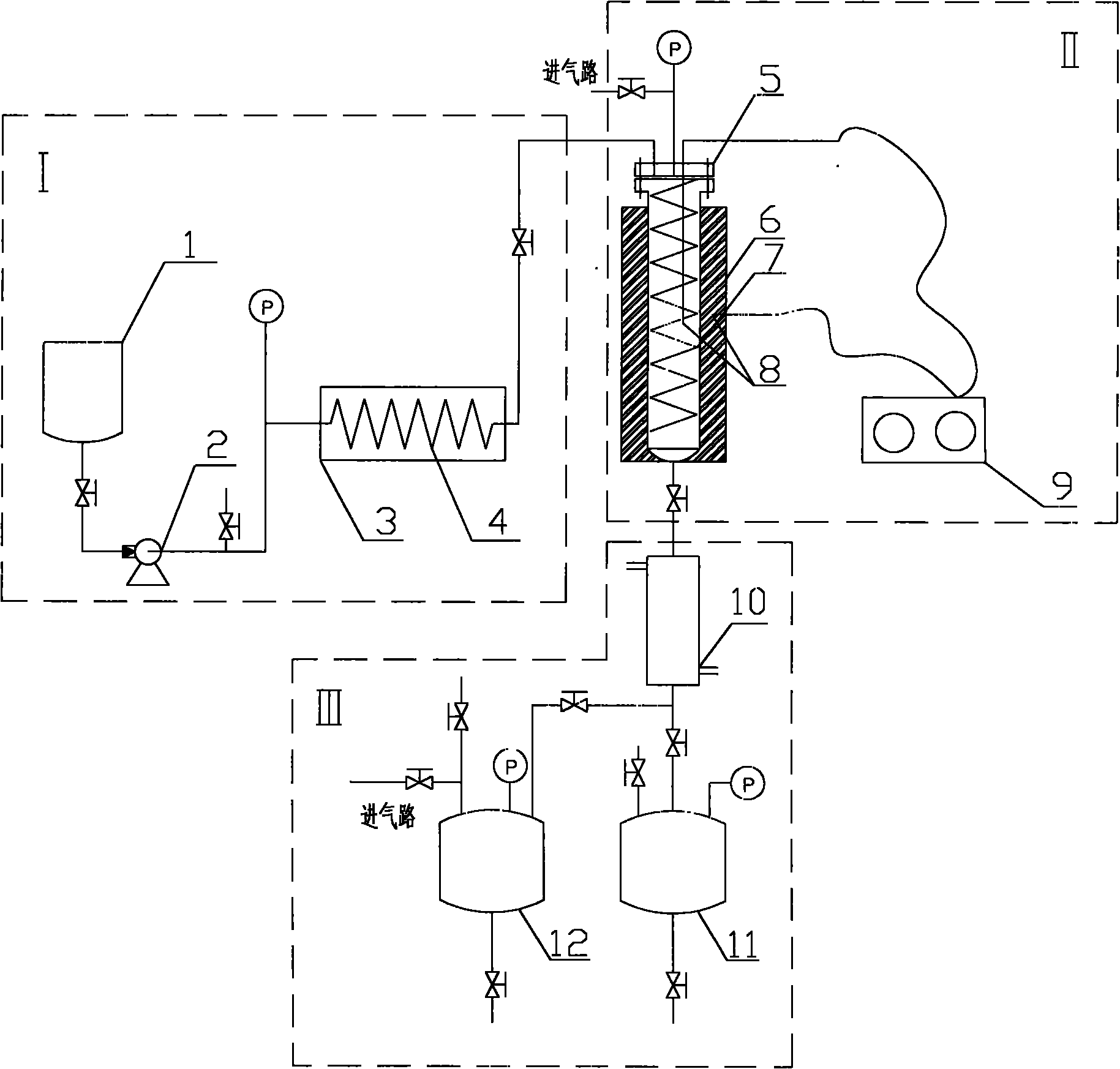

[0026] Such as figure 1 As shown, the cellulosic biomass compression percolation hydrolysis system is composed of the following three parts: a reaction medium feeding system I composed of a liquid feeding tank 1, a metering pump 2, an electric sand bath 3 and a preheating coil 4; Compression percolation reactor assembly II composed of diafiltration reactor 5, jacket heater 6, compression spring 7, thermocouple 8 and temperature controller 9; composed of cooling pipe 10, sampling tank 11 and buffer receiving tank 12 Liquid Product Collection Apparatus III.

[0027] Taking the sweet sorghum slag after squeezing the juice as the raw material for hydrolysis as an example, the sweet sorghum slag with a size of less than 1cm is properly moistened, put into the compression percolation reactor 5, and apply a certain pressure to compact the material with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com