Method for performing hydrogenation on liquid-state organic hydrogen storage carrier through batch reaction kettle

A hydrogen storage carrier, intermittent technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of high hydrogen storage system, interruption of dehydrogenation reaction, etc., to improve the hydrogenation effect and improve the hydrogenation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

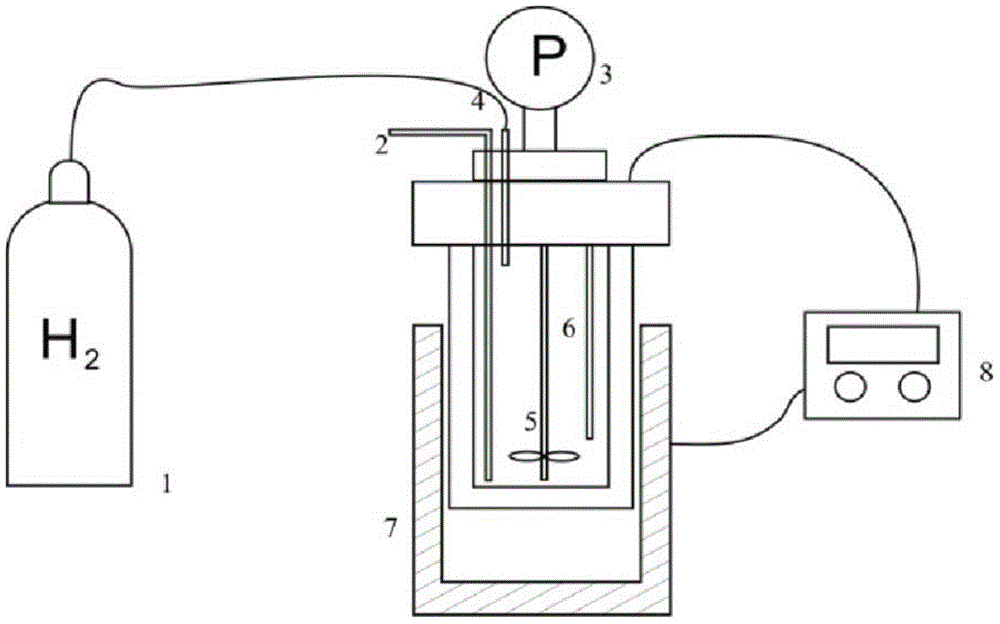

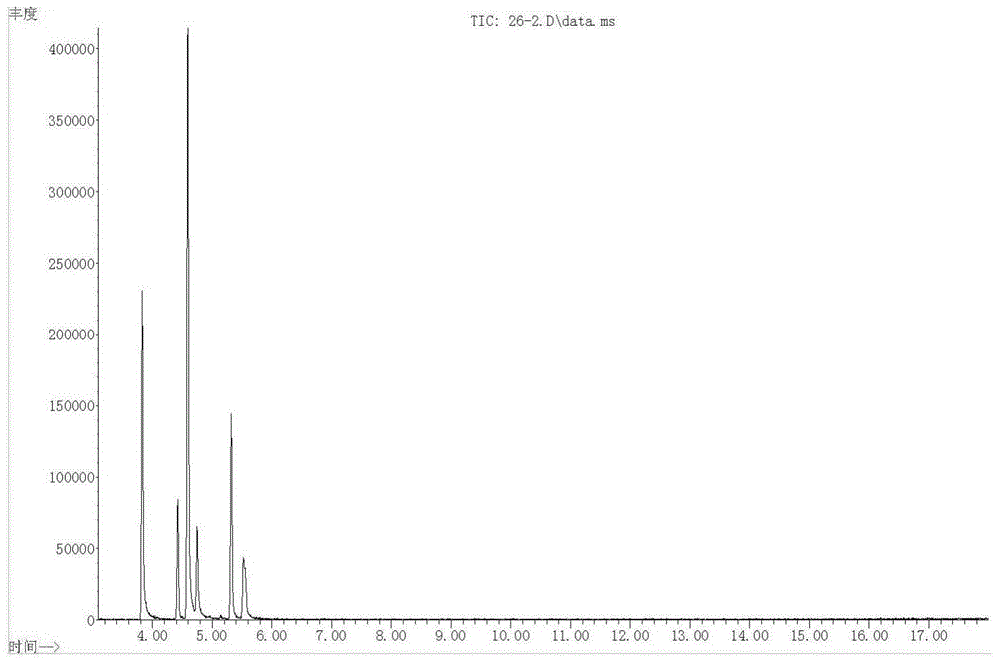

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

[0021] The liquid organic hydrogen storage carrier is a hydrogen storage system that can be liquid at normal temperature and pressure, including at least two different hydrogen storage components, the hydrogen storage components are unsaturated aromatic hydrocarbons or heterocyclic unsaturated compounds, and at least One hydrogen storage component is a low melting compound having a melting point below 80°C.

[0022] Further, the hydrogen storage component is selected from heterocyclic unsaturated compounds, and the heteroatoms in the heterocyclic unsaturated compounds are one or more of N, S, O and P.

[0023] Further, the total number of heterocycles and aromatic rings in the heterocyclic unsaturated compound is 1-20, and the total number of heteroatoms is 1-20.

[0024] Further, relative to the total mass of the liquid hydrogen storage system, the mass fraction of the low m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com