Cerium-containing hydrodesulfurization catalysts and uses

a technology of hydrodesulfurization catalyst and cerium-containing catalyst, which is applied in the direction of catalyst activation/preparation, metal/metal-oxide/metal-hydroxide catalyst, etc., can solve the problems of sulfur presence in fuels that hamper the hydrocracking process, severe health problems and ecological damage, and achieve the effect of reducing the sulfur content of the hydrocarbon stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0079]MATERIALS: Ceric ammonium nitrate, ACS reagent grade, was procured from Riedel-de Haen AG, USA. Acetylacetone, dimethoxyethane, isopropanol, sodium hydride and sodium borohydride were procured from Fluka Chemie AG, Buchs, Switzerland. Tetraethyl-orthosilicate (TEOS), pluronic P123, i.e., a symmetric triblock copolymer comprising poly(ethylene oxide) (PEO) and poly(propylene oxide) (PPO) in an alternating linear fashion, PEO-PPO-PEO, with a molar mass (Mn) of ˜5,800 g / mol, anhydrous cobalt chloride (98%), DBT (98%), and dodecane were purchased from Sigma-Aldrich. Ammonium molybdate (VI) tetrahydrate (99%) was purchased from ACROS organics. Deionized water was generated in-house using a Thermo Scientific Barnstead NANOPURE filter after distillation with a Labstrong FiSTREEM™ II Glass Still distiller.

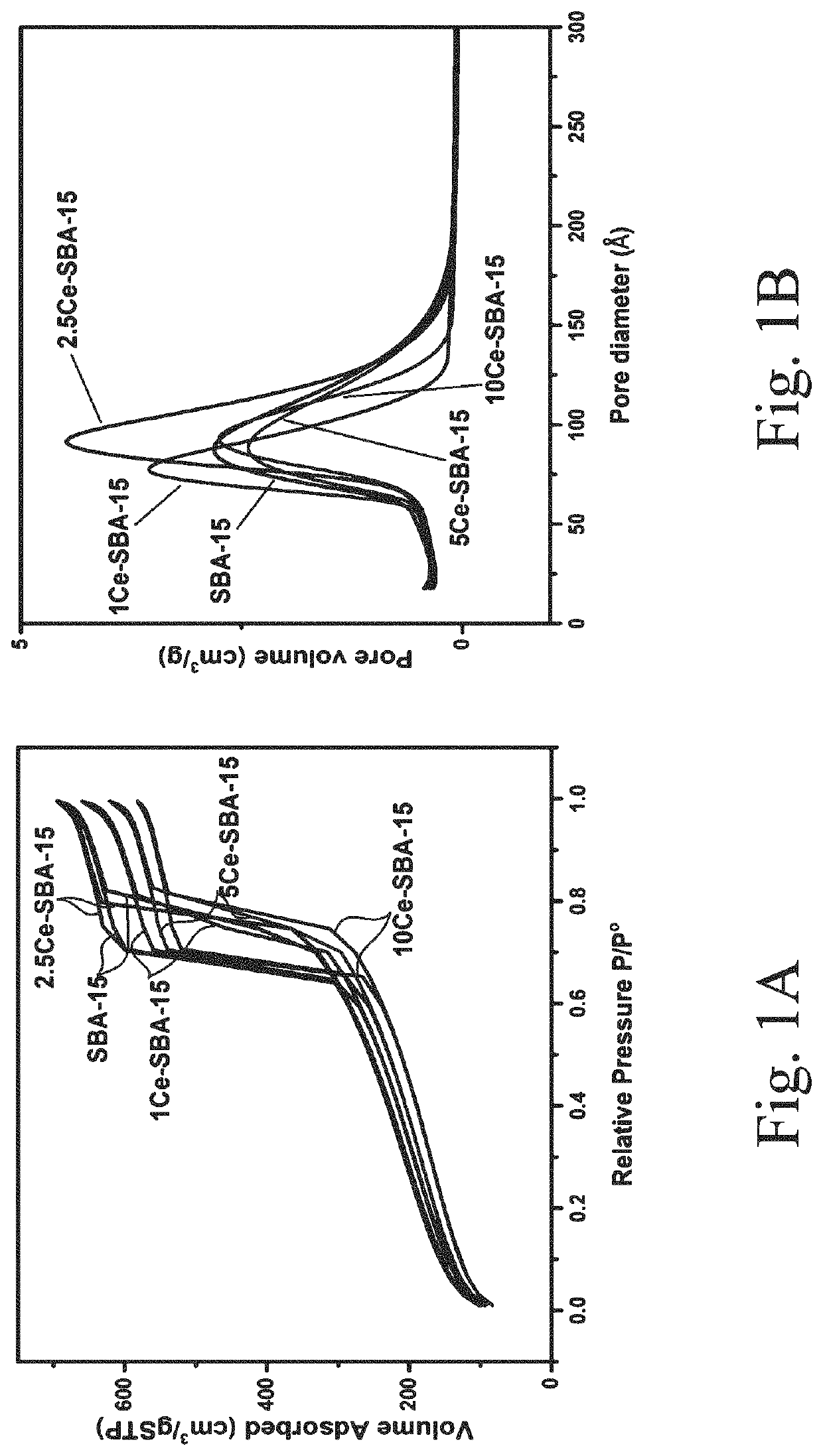

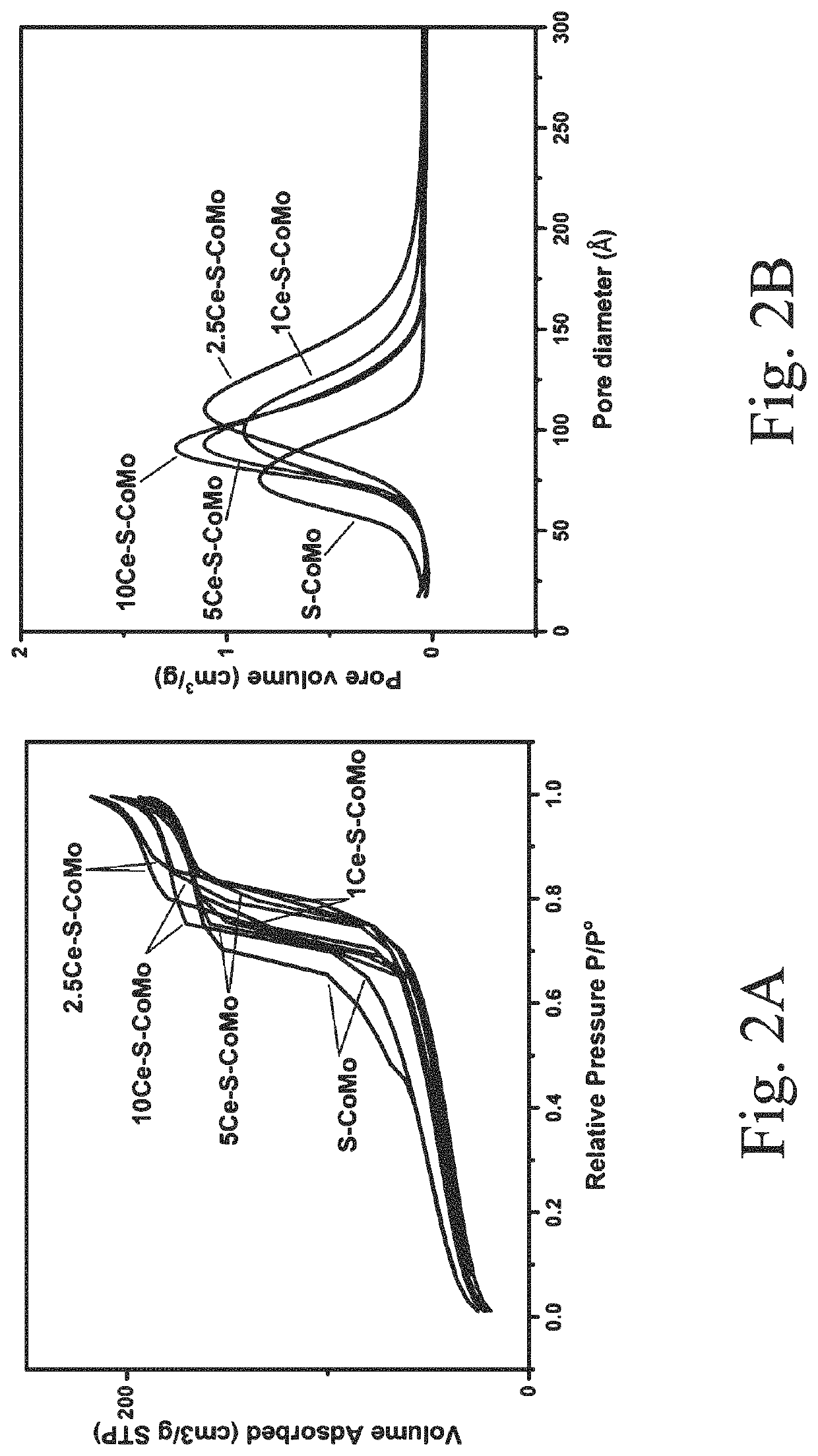

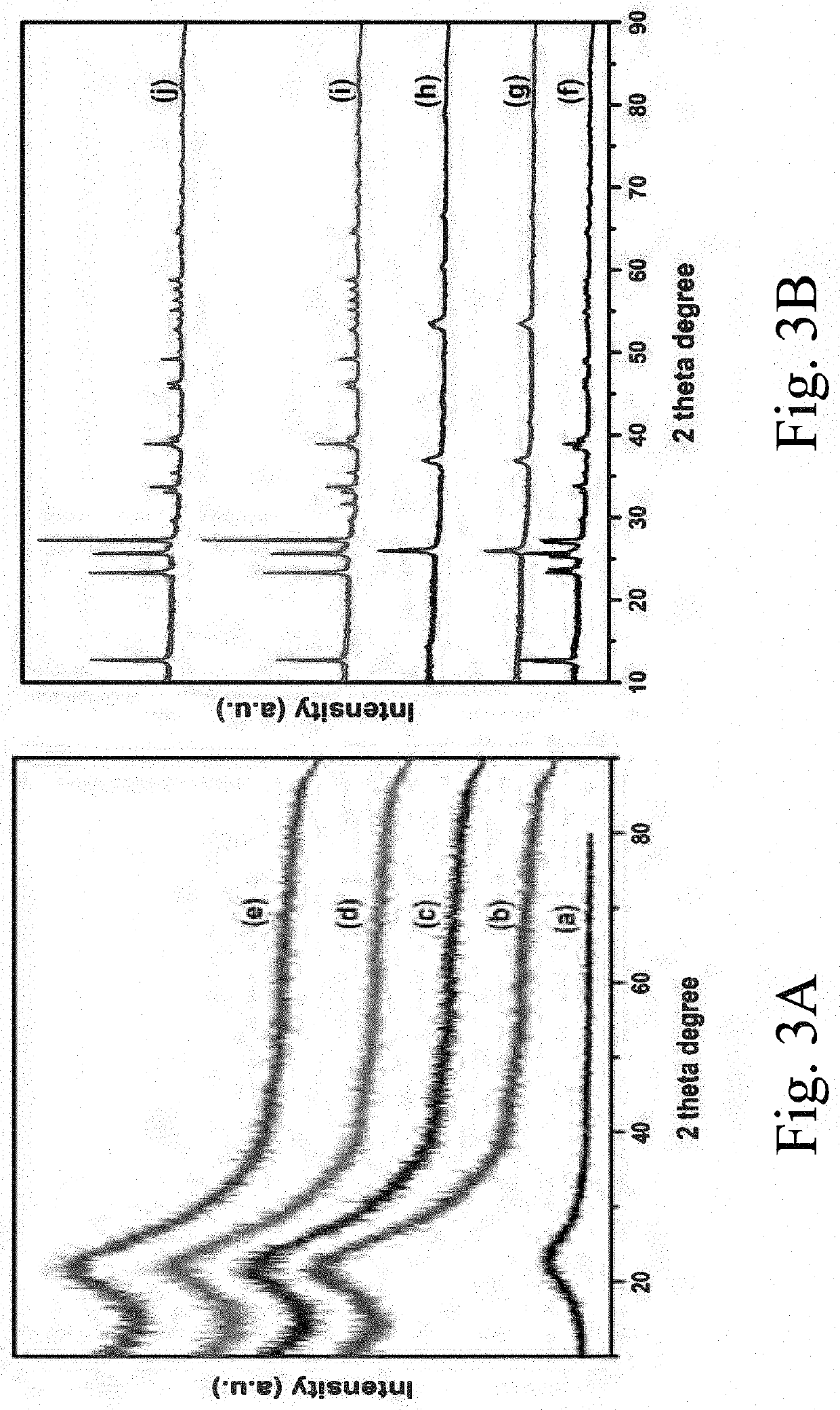

[0080]SYNTHESIS OF SBA-15 AND CE-MODIFIED SBA-15: Mesoporous SBA-15 and series of Ce-SBA-15 (1 to 10 wt. %) catalysts were synthesized, with slight modification (e.g., the addition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com