Method for preparing acrolein through catalysis of glycerol liquid phase dehydration by using pyridine ion liquid

An ionic liquid, a technology for catalyzing glycerol, which is applied in the field of organic chemistry to achieve the effects of high activity, high product selectivity and yield, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

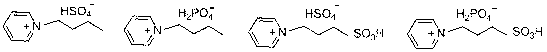

Image

Examples

Embodiment 1

[0017] Take 0.1 mol of pyridine in a four-neck flask, add equimolar n-bromobutane into a constant pressure titration funnel, 2 Stirred under protective conditions for 12 h, the product was washed with ethyl acetate and then vacuum-dried for 8 h to obtain 0.1 mol of brominated n-butylpyridine [Bpy]Br as light yellow viscous oily liquid. At 90 °C, equimolar concentrated sulfuric acid was added dropwise to [BPy]Br, stirred for 6 h, the product was washed with ether and then dried in vacuum to obtain the ionic liquid [BPy]HSO 4 .

[0018] Weigh the [BPy]HSO prepared above 4 Catalyst 5 mmol, glycerin 1.0 mol, stirred and heated up to 250 °C for batch reaction, fully reacted until no distillate was produced, then sampled for gas chromatographic analysis. Analysis showed that the conversion rate of glycerol was 100%, and the yield of acrolein was 32.5%.

Embodiment 2

[0020] [BPy]HSO 4 Synthesis as in Example 1. Weigh the [BPy]HSO prepared above 4 Catalyst 5 mmol, glycerin 1.0 mol, stirred and heated up to 300 °C for batch reaction, fully reacted until no distillate was produced, and samples were taken for gas chromatographic analysis. The analysis shows that the conversion rate of glycerol is 100%, and the yield of acrolein is 48.1%.

Embodiment 3

[0022] [BPy]HSO 4 Synthesis as in Example 1. Weigh the [BPy]HSO prepared above 4 Catalyst 0.012 mol, glycerol 1.0 mol, stirred and heated up to 250 °C for batch reaction, fully reacted until no distillate was produced, then sampled for gas chromatography analysis. Analysis showed that the conversion rate of glycerol was 100%, and the yield of acrolein was 50.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com