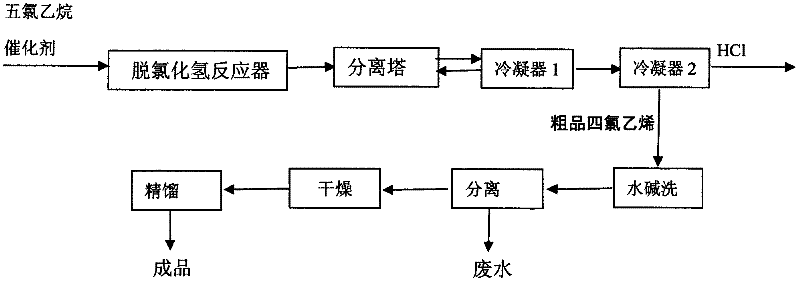

Method for preparing tetrachloroethylene by liquid-phase catalysis of pentachloroethane

A technology of tetrachlorethylene and pentachloroethane, which is applied in the field of preparation of organic chlorinated hydrocarbons, can solve the problems of expensive catalysts, high production costs, and high material requirements, and achieve flexible production methods, convenient operation, and high material utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

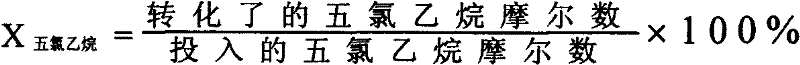

[0026] Embodiment 1: batch method

[0027] Reactor capacity is 4 liters, in reactor, add the pentachloroethane 2800ml (4662 grams) of purity 98%, by weight percentage, pentachloroethane: catalyst=1: 0.0031~0.005, add aluminum chloride 20.5 grams, Potassium chloride 2.3 grams, use a heating tube to heat up to 120 ° C, the pressure gauge is 0.01Mpa, reflux for 10 hours, monitor the composition of the reaction solution every 2 hours, when the pentachloroethane is less than 1%, the reaction is terminated, and the tail gas hydrogen chloride is recovered with water , Change the distillation operation to obtain 2278ml (3693 grams) of tetrachloroethylene crude product, through gas chromatography analysis, tetrachloroethylene content 95.01% in the sample, conversion rate 98.80%, selectivity 94.80%, yield 93.66%.

Embodiment 2

[0028] Embodiment 2: continuous method

[0029]Reactor capacity is 4 liters, and in reactor, adding purity is 2800ml (4520 grams) of tetrachlorethylene of 99.8% and is mother liquor, adds catalyzer by 1: 0.001~0.003 with raw material weight percentage, aluminum chloride 10.6 grams, cesium chloride 2.7 grams, heating the reaction solution with a heating tube to heat up to 80°C, adding pentachloroethane with a purity of 98%, pentachloroethane dripping at a flow rate of 1ml per minute, and continuing to heat up for 20 to 30 minutes. After the reaction temperature reaches 120°C, The pressure gauge is 0.01Mpa. Increase the amount of pentachloroethane added to 7.2ml per minute, keep the volume of the amount of pentachloroethane added and the amount of tetrachlorethylene distilled equal, and also keep the content of the catalyst unchanged, and absorb the hydrogen chloride in the tail gas with water for 5 hours Stop adding raw material afterward, total addition 2218ml (3693 grams), r...

Embodiment 3

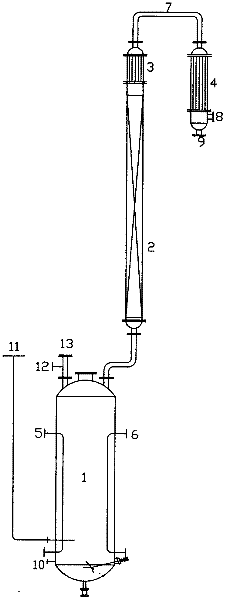

[0030] Embodiment 3: batch method

[0031] at 30 meters 3 21 m of pentachloroethane with a purity of 98% was added to Reactor 1 3 (34.965 tons), add 119 kilograms of aluminum chloride, 21 kilograms of potassium chloride catalyzers by weight percentage, stir, heating pipe 5.6 logical steam is warming up to 120 ℃, gas phase outlet 8 accesses hydrochloric acid device, reflux reaction 12 hours, every Monitor the composition of the reaction solution for 2 hours, the content of pentachloroethane is less than 1% as the end point, change the distillation operation, and finally obtain 16.73 meters of crude tetrachlorethylene 3 (27.023 tons), analyzed by gas chromatography, the tetrachloroethylene content in the sample was 95.27%, the conversion rate was 98.70%, the selectivity was 92.85%, and the yield was 91.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com