Non-loading type nickel-based bio-oil hydrodeoxygenation catalyst and preparation method thereof

A technology of deoxidation catalyst and nickel-based catalyst, which is applied in the direction of carbon-based compound preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of increasing density, low equipment requirements, and cheap and easy-to-obtain reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

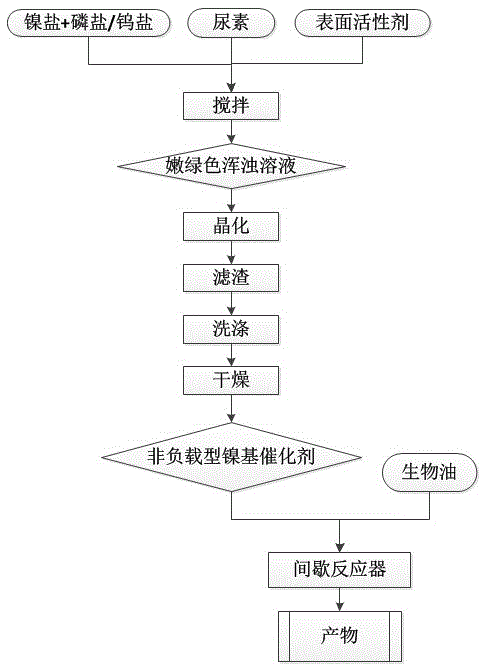

[0022] A kind of unsupported nickel-based bio-oil hydrodeoxygenation catalyst of the present invention and preparation method thereof, such as figure 1 As shown, the specific steps include:

[0023] (1) Dissolve the surfactant in water to prepare a solution with a mass fraction of 0.9-3.6%, and then dissolve urea, soluble nickel salt, soluble phosphorus salt or (and) soluble tungsten salt in the above solution respectively, in which urea The mass fraction of the soluble nickel salt is 0.9-3.6%, the mass fraction of the soluble nickel salt is 0.3-1.1%, the mass fraction of the soluble phosphorus salt or (and) soluble tungsten salt is 0.1-0.4%, and the magnetic stirring is 5-15min, forming a light green turbidity solution.

[0024] (2) The turbid solution obtained in step (1) was crystallized at 100-300° C. for 2-16 hours, and filtered to obtain a filter residue.

[0025] (3) Wash the filter residue obtained in step (2) with water and absolute ethanol for 3 to 5 times, and the...

example 1

[0030] The present invention is a non-supported nickel-based bio-oil hydrodeoxygenation catalyst and a preparation method thereof, and the specific steps include:

[0031] (1) Dissolve the surfactant in water to make a solution with a mass fraction of 0.9%, and then dissolve urea, soluble nickel salt, soluble phosphorus salt and soluble tungsten salt in the above solution respectively, wherein the mass fraction of urea is 0.9% %, the mass fraction of soluble nickel salt is 0.3%, the mass fraction of soluble phosphorus salt is 0.1%, the mass fraction of soluble tungsten salt is 0.1%, magnetic stirring for 10min forms a light green turbid solution.

[0032] (2) The turbid solution obtained in step (1) was crystallized at 100°C for 15 hours, and filtered to obtain a filter residue.

[0033] (3) Wash the filter residue obtained in step (2) four times with water and absolute ethanol, and then perform centrifugation at a speed of 4000 rpm for 10 minutes. Finally, dry the precipitate...

example 2

[0039] The present invention is a non-supported nickel-based bio-oil hydrodeoxygenation catalyst and a preparation method thereof, and the specific steps include:

[0040] (1) Dissolve the surfactant in water to make a solution with a mass fraction of 1.8%, and then dissolve urea, soluble nickel salt and soluble tungsten salt in the above solution respectively, wherein the mass fraction of urea is 1.8%, and the soluble nickel The mass fraction of salt is 0.6%, the mass fraction of soluble tungsten salt is 0.2%, and magnetically stirred for 15 minutes to form a bright green turbid solution.

[0041] (2) The turbid solution obtained in step (1) was crystallized at 150° C. for 10 h, and filtered to obtain a filter residue.

[0042] (3) Wash the filter residue obtained in step (2) three times with water and absolute ethanol, and then perform centrifugation at a speed of 3000 rpm for 15 minutes. Finally, dry the precipitate in an oven for 5 hours at a temperature of 100°C, an unsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com