Reutilization method of water-base fracturing flowback fluid

A fracturing flowback fluid and water-based fracturing technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as water quality reuse, improve recovery rate, expand Use range, effect of expanding the range of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

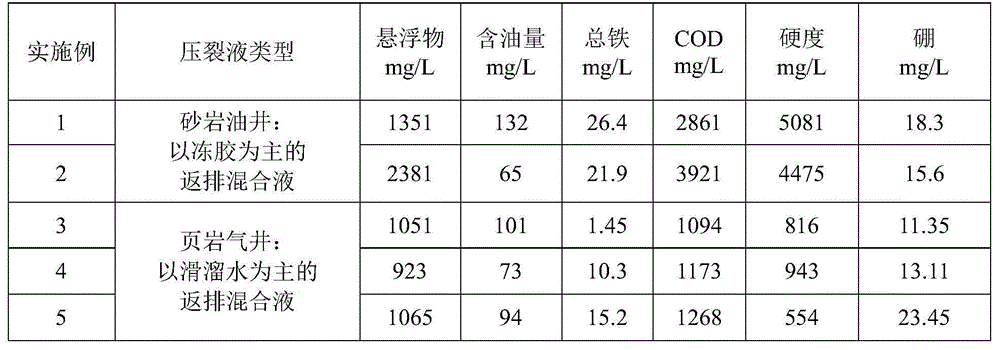

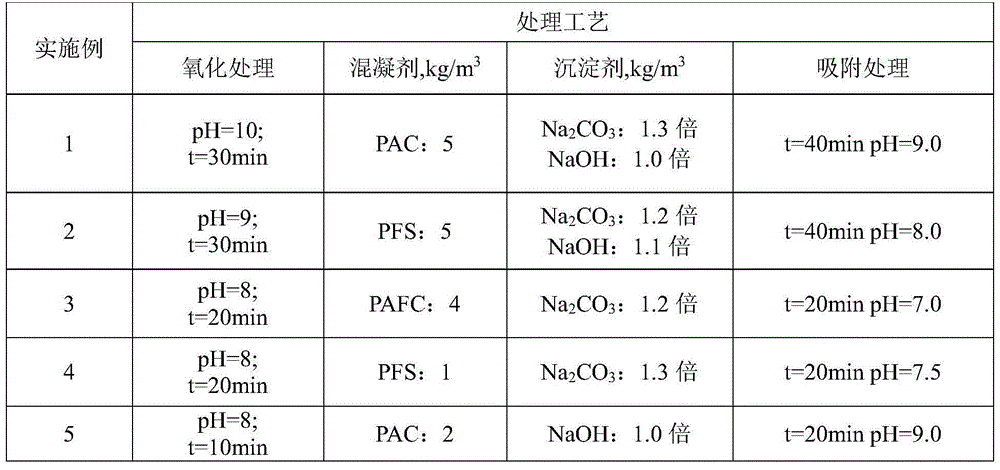

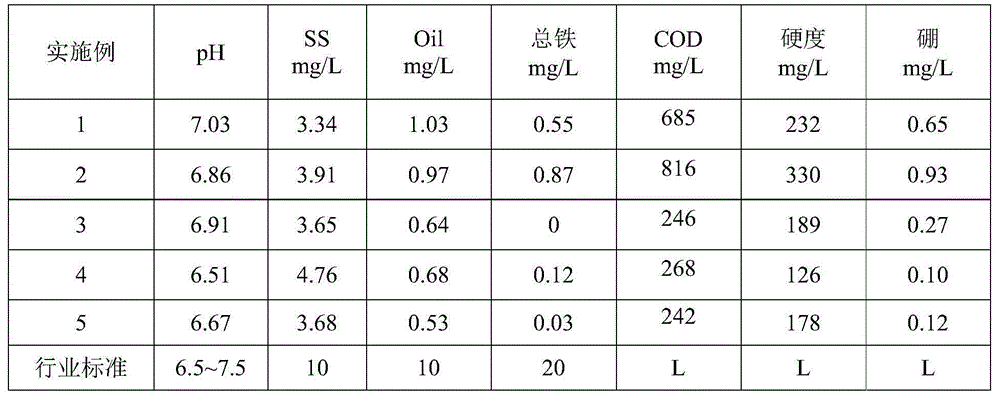

[0025] Oil-water separation was performed on the flowback fluid of an unconventional oil well fracturing (fracturing stage 10) in a tight sandstone reservoir in Zhongyuan Oilfield, and 10m of the separated effluent was taken 3 , to analyze the nature of pollutants, the suspended matter is 1351mg / L, the oil content is 132mg / L, the total iron is 26.4mg / L, the COD is 2861.2mg / L, the hardness is 3624mg / L, and the boron content is 18.36mg / L. Adjust the pH of the water sample to 10 and then pump it into the ozone oxidation reactor. The ozone concentration is 30-40 mg / L. After 30 minutes of reaction, the wastewater is treated with flocculation and sedimentation; add 5 kg / m 3 Add the precipitating agent after dissolving completely (1.3 times of calcium ion stoichiometric reaction measure add sodium carbonate, magnesium ion stoichiometric reaction measure 1.0 times add sodium hydroxide) and stir evenly, white precipitate appears, add under slow speed stirring The polyacrylamide solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com