Plasma incineration waste treatment equipment

A technology of plasma and garbage incineration, which is applied in the direction of mechanical equipment, lighting and heating equipment, incinerators, etc., can solve the problems of explosion, large power consumption, and large power consumption, and achieve good safety performance, reduce power consumption, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

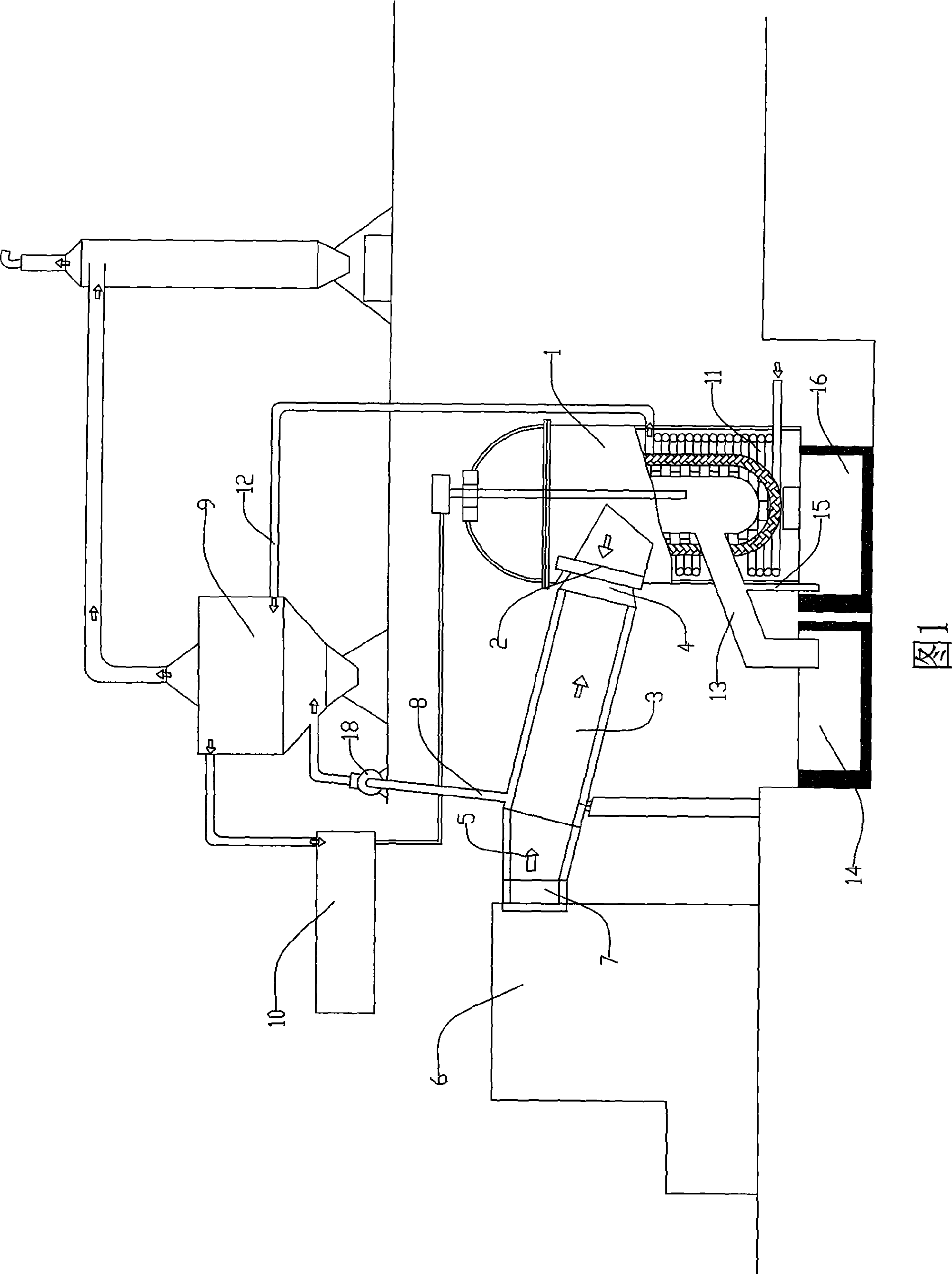

[0007] A kind of plasma incineration garbage processing equipment, as shown in Fig. 1, comprises plasma incineration garbage furnace 1, the garbage feed port 2 of the garbage incinerator is connected with the discharge port 4 of the garbage preheating device 3, and the inlet of the garbage preheating device The feed port 5 is in turn connected to the discharge port 7 of the garbage crushing device 6 . The garbage preheating device can be a horizontal rotary furnace, which is the prior art. It is inclined downward from the feed port to the discharge port, and there is a rotating device in it to drive the rotation of the garbage transported to the plasma incineration garbage furnace through its interior. . The garbage crushing device can be a pressure plate driven by a hydraulic cylinder to reciprocate up and down. The pressure plate is driven by the pressure cylinder to smash the garbage up and down repeatedly to break the garbage. It is especially easy to smash the bottles and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com