Method for flue gas denitrification by organic waste gas

A technology of organic waste gas and flue gas, which is applied in the field of flue gas denitrification, can solve the problems of difficult industrialization and high energy consumption, and achieve the effects of high operational safety, saving investment, saving land occupation and device construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

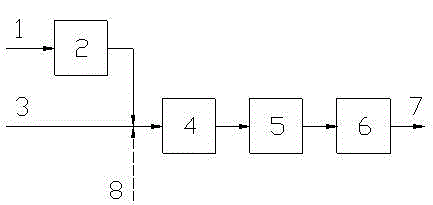

[0027] Such as figure 1As shown, the method for flue gas denitrification using organic waste gas in the present invention generally includes an organic waste gas desulfurization reactor 2 , a heater 4 , a waste gas purification reactor 5 and an energy recovery unit 6 . According to the nature of the organic waste gas, the organic waste gas can be pre-desulfurized by using lye, alcohol amine solution or desulfurizer, and then the organic waste gas is introduced into the flue gas, and an appropriate amount of oxygen-containing gas is introduced to make organic hydrocarbons, NOx and oxygen The concentration meets the requirements of the reaction. After the temperature is raised to 100-500°C by the heater, the mixed exhaust gas enters the exhaust gas purification reactor. Here, in the presence of a denitrification catalyst, the NOx in the exhaust gas and the organic matter undergo a redox reaction, and the NOx is converted into N 2 , the organic matter is oxidized to CO 2 and H...

Embodiment 1

[0031] The NOx concentration in boiler flue gas of an enterprise is 500mg / Nm 3 , the gasoline loading tail gas is treated by the oil gas recovery device, the non-methane total hydrocarbons in the tail gas (expressed as CH 4 meter) concentration 10000mg / Nm 3 . After mixing: total non-methane hydrocarbons in exhaust gas (as CH 4 ) to NOx molar ratio of 3:1; oxygen to total hydrocarbon molar ratio of 1.5:1.

[0032] Operating conditions: the mixed gas is heated by an electric heater, the heating temperature is 270°C, and the operating space velocity is 3000h -1 , in the presence of a denitrification catalyst for redox reactions. The catalyst support is Al 2 o 3 , the active components are Pt and Pd, and the loadings are 1.5% and 1.0%, respectively.

[0033] After measurement, the NOx concentration in the purified flue gas is 50mg / Nm 3 , non-methane total hydrocarbons (in CH 4 meter) concentration 100mg / Nm 3 .

Embodiment 2

[0035] The concentration of NOx in boiler flue gas of a factory is 500mg / Nm 3 , non-methane total hydrocarbons (in CH 4 meter) concentration 6000mg / Nm 3 , H 2 S concentration 50mg / Nm 3 .

[0036] Operation steps and operating conditions: (1) First, use activated carbon loaded with ZnO desulfurization agent to desulfurize the organic waste gas; (2) Introduce the organic waste gas and air into the flue gas containing NOx; after mixing, the total non-methane hydrocarbons in the waste gas (in CH 4 ) to NOx molar ratio is 5:1; oxygen to total hydrocarbon molar ratio is 2:1; (3) Heating the mixed gas with an electric heater, the heating temperature is 310°C, and the operating space velocity is 3000h -1 . The active components of the catalyst used were Co, manganese oxide and Pt, the loadings were 5.0%, 3.5% and 1.0%, respectively, and the carrier was Al 2 o 3 .

[0037] After measurement, the NOx in the purified flue gas is 150mg / Nm 3 , non-methane total hydrocarbons (in C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com