Waste plastic separating method and system based on image recognition

An image recognition and separation system technology, which is applied in the field of waste plastic separation and system based on image recognition, can solve the problems of dirty surface of waste plastic, low efficiency, and inability to reflect the nature of waste plastic material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

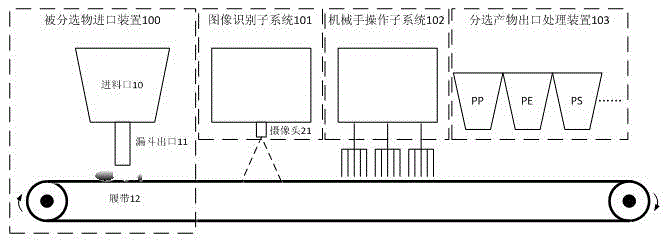

[0070] Embodiment 1: Different types of waste plastics separated from oversize, such as PE, PP, PS, PVC, etc.;

[0071] exist image 3 In the shown embodiment 1, the sorting system needs to follow the implementation requirements of the sorting system, keep all kinds of input and output signals smooth and effective, and the software and hardware run normally. The goal of sorting is to separate the mixed waste plastics in the garbage sieve and classify them into different waste plastics at the same time. according to figure 2 Steps 1-6 are shown for sorting, and each step is described as follows:

[0072] Step 1: Preparation before feeding. Sieve the garbage at a certain speed, such as 1m 3 The processing capacity per minute enters the hopper, shakes the hopper to loosen and evenly screen the garbage;

[0073]Step 2: Through a narrow and long outlet, the waste on the screen is evenly diluted on the crawler. The aspect ratio of the outlet should be kept at a certain value ...

Embodiment 2

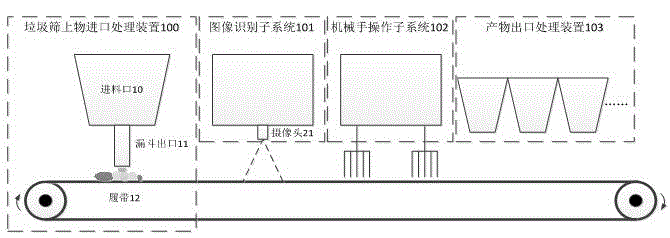

[0098] Example 2: Separation of mixed waste plastics from garbage oversize.

[0099] exist Figure 4 In the shown embodiment 2, the sorting system needs to follow the implementation requirements of the sorting system, keep all kinds of input and output signals smooth and effective, and the software and hardware run normally. The goal of sorting is to separate the mixed waste plastics in the garbage sieve. according to image 3 Steps 1-6 are shown for sorting, and each step is described as follows:

[0100] Step 1: Preparation before feeding. Sieve the garbage at a certain speed, such as 1.5 m 3 The processing capacity per minute enters the hopper, shakes the hopper to loosen and evenly screen the garbage;

[0101] Step 2: Through a narrow and long outlet, the waste on the screen is evenly diluted on the crawler. The aspect ratio of the outlet should be kept at a certain value to facilitate manipulator operation, for example, 10:1—15:1, and the track width should be selec...

Embodiment 3

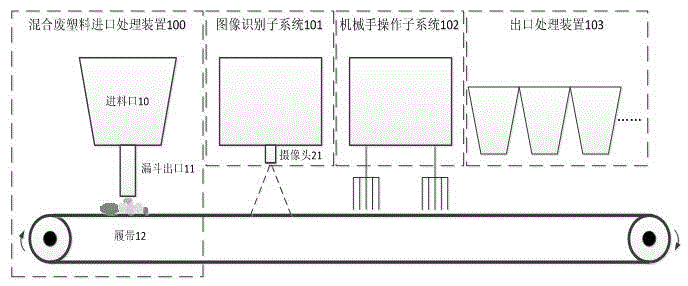

[0123] Example 3: Separation of sundries from mixed waste plastics.

[0124] exist Figure 5 In the shown embodiment 3, the sorting system needs to follow the implementation requirements of the sorting system, keep all kinds of input and output signals smooth and effective, and the software and hardware run normally. The goal of sorting is to separate the impurities in mixed waste plastics and improve the purity of mixed waste plastics. according to image 3 Steps 1-6 are shown for sorting, and each step is described as follows:

[0125] Step 1: Preparation before feeding. Mix the waste plastic at a certain speed, such as 1.0 m 3 The processing capacity per minute enters the hopper, shakes the hopper to loosen and evenly mix the waste plastics;

[0126] Step 2: Through a narrow and long outlet, the mixed waste plastic flow is evenly spread on the track. The aspect ratio of the exit should be kept at a certain value to facilitate manipulator operation, such as 8:1—13:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com