Kitchen waste preprocessing technology

A food waste and pretreatment technology, applied in the direction of solid waste removal, etc., can solve the problems of harmless treatment or low resource conversion rate, and achieve the effect of improving resource conversion rate, complete shape, and uniform garbage particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

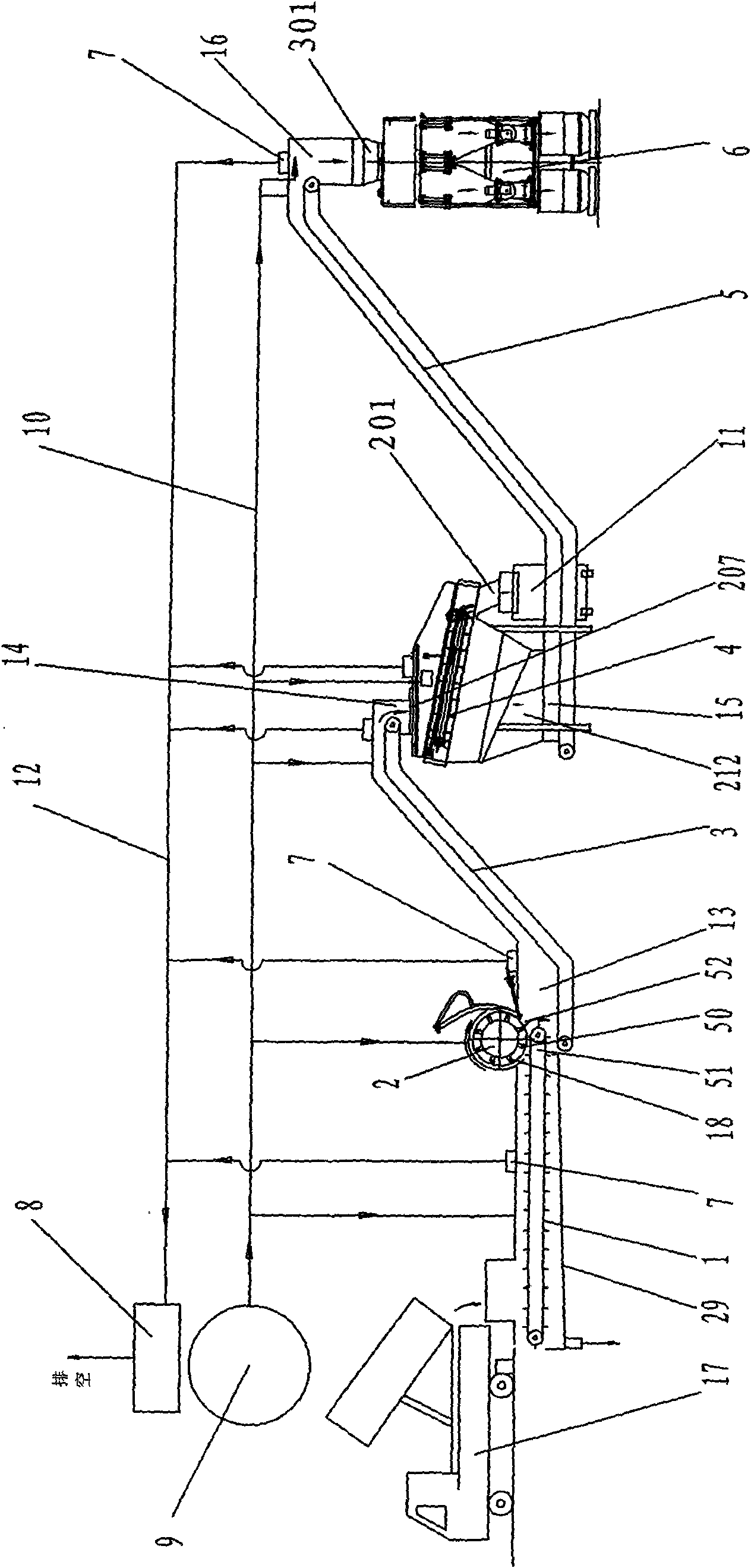

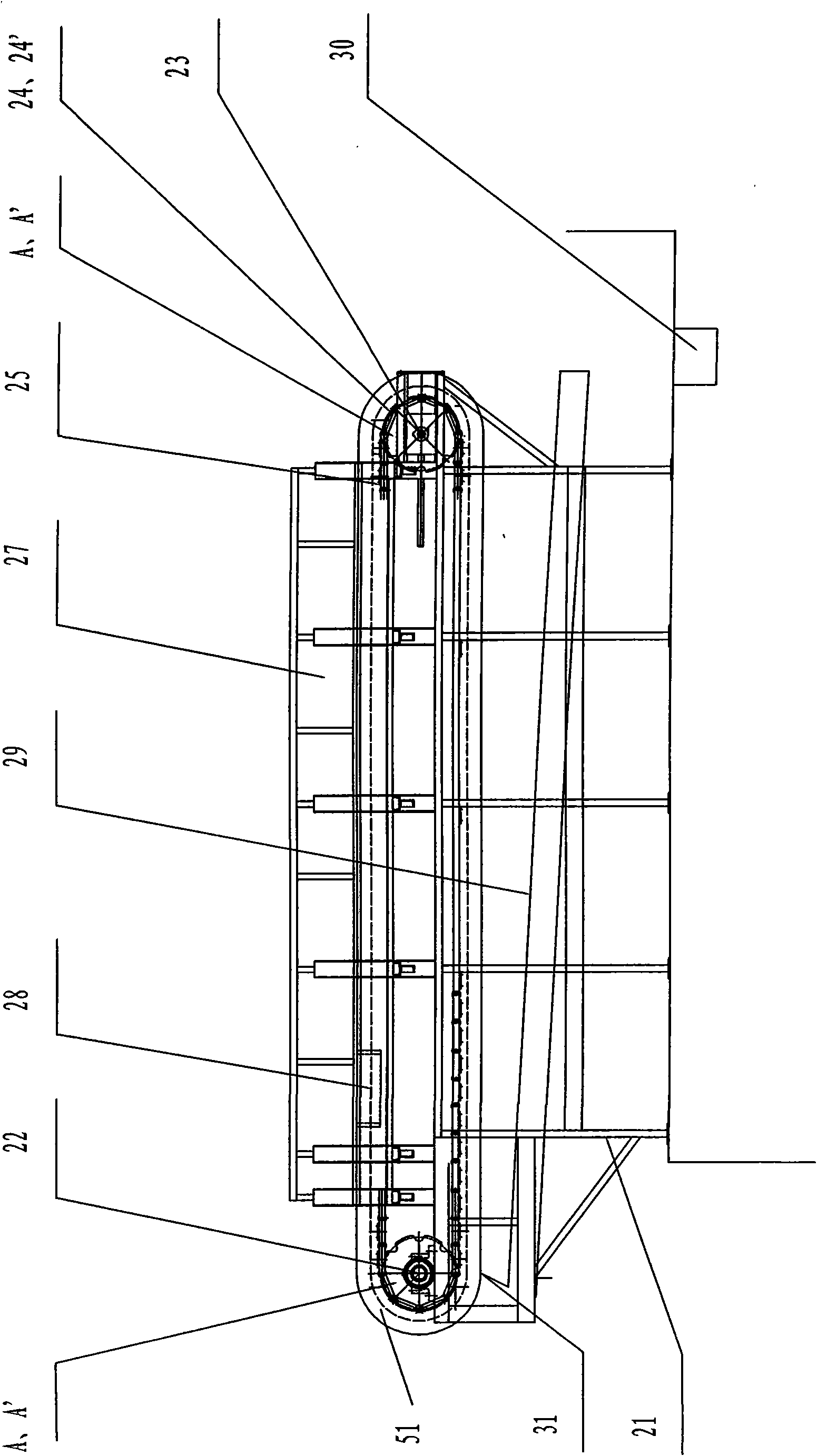

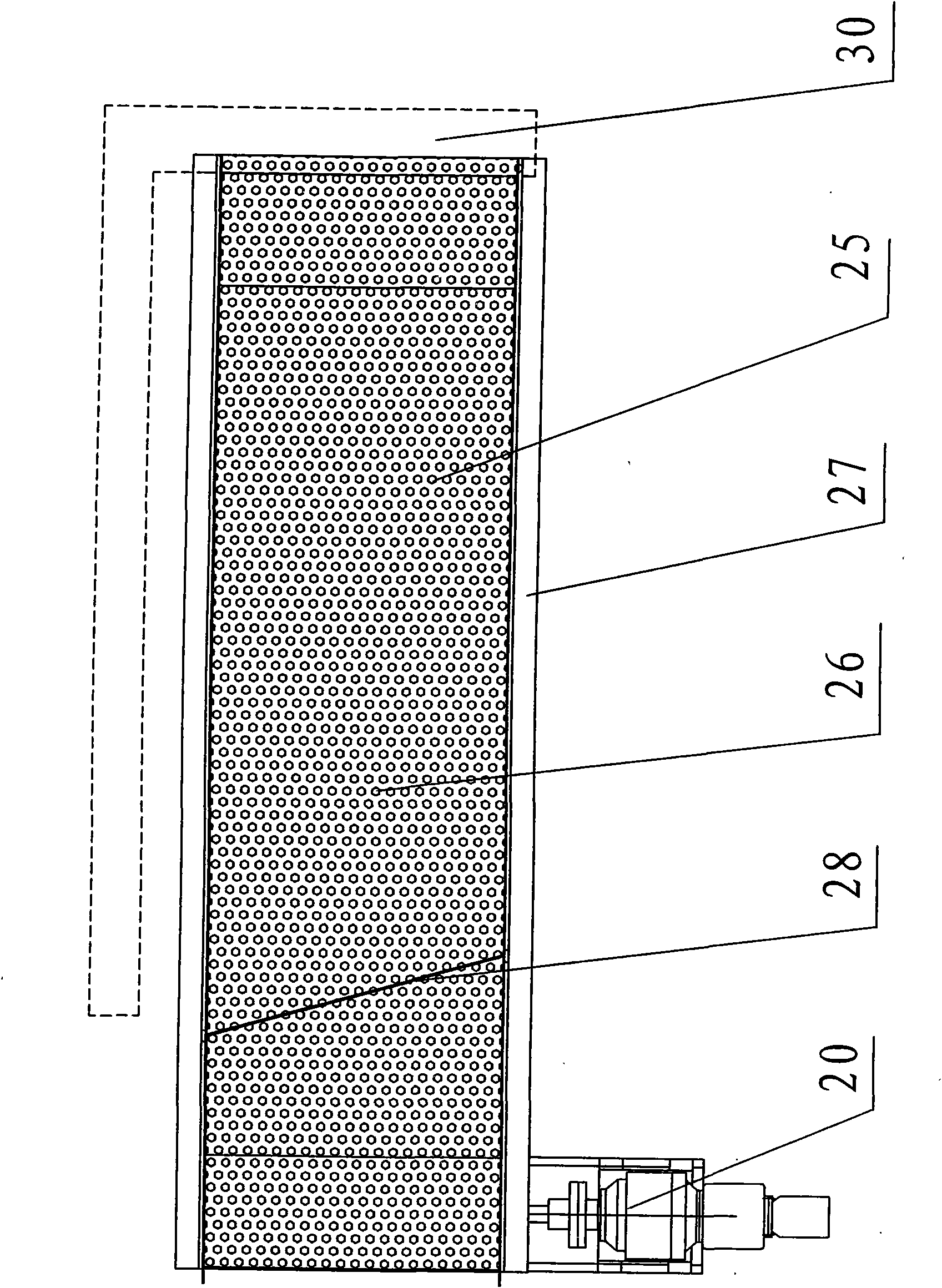

[0029] Such as figure 1 As shown, the equipment used in the food waste pretreatment process of the present invention includes a food waste receiving machine 1, a balanced cloth bag breaking machine 2, a first conveyor 3, a vibrating grid sorter 4, and a second conveyor 5 , a fully automatic distributing bin 6 and a programmable logic controller (PLC), the balanced bag breaking integrated machine 2 is installed on the discharge end 51 of the food waste receiving machine 1, the balanced bag breaking integrated machine 2 includes a bag breaking device and a material distribution device, The bag breaking feed port 50 of the bag breaking device is located above the discharge end 51 of the food waste receiving machine 1, and the first feed port 13 of the first conveyor 3 is located at the bag breaking discharge port of the balanced bag breaking machine 2. Below the mouth 52 and the discharge end 51 of the food waste receiving machine 1, the first discharge port 14 of the first conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com