Harmless and resourceful treatment method for waste lithium battery electrolyte

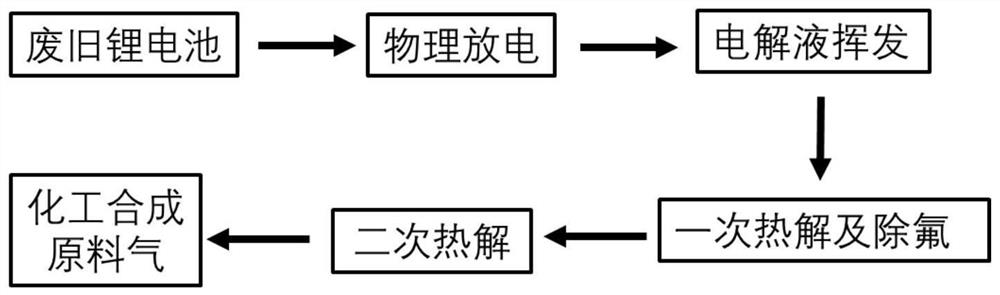

A technology for waste lithium batteries and treatment methods, which is applied in the field of harmless and resourceful treatment of waste lithium battery electrolytes, can solve problems such as reduced liquid electrolyte content, complex components, and environmental pollution, and achieve strong technical applicability and resource utilization. The effect of high conversion rate and avoiding environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for harmless and resourceful treatment of waste lithium battery electrolyte, comprising the following steps:

[0025] (1) Discharge 8 18650 waste lithium batteries to 0V under the conditions of waste lithium battery and conductive graphite powder mass ratio 1:3, stirring time 30min, stirring rate 200rpm / mim;

[0026] (2) Under the nitrogen flow, the discharged waste lithium battery was heated at 120° C. for 200 minutes, and 18.5 g of the recovered electrolyte was condensed.

[0027] (3) Pyrolyze the recycled electrolyte at 550°C for 3 minutes in a nitrogen atmosphere. After pyrolysis, pass the pyrolysis gas through calcium oxide powder at 550°C with nitrogen flow to remove fluorine. The weight of calcium oxide powder increases by 0.42 g.

[0028] (4) Pyrolyze the fluorine-removing pyrolysis gas flow at 680°C for 2 minutes, and finally cool and store the pyrolysis gas. All organic components of the electrolyte are pyrolyzed and converted into gaseous products, ...

Embodiment 2

[0030] A method for harmless and resourceful treatment of waste lithium battery electrolyte, comprising the following steps:

[0031] (1) Discharge 8 18650 waste lithium batteries to 0V under the conditions of waste lithium battery and conductive graphite powder mass ratio 1:2, stirring time 60min, stirring rate 150rpm / mim;

[0032] (2) Under nitrogen flow, the discharged waste lithium battery was heat-treated at 150° C. for 160 min, and 18.7 g of electrolyte was condensed and recovered.

[0033] (3) Pyrolyze the recovered electrolyte at 450°C for 5 minutes in an argon atmosphere, and after pyrolysis, pass the pyrolysis gas through alumina powder at 450°C with argon flow to remove fluorine, and the alumina powder increases Weighs 0.43g.

[0034] (4) Pyrolyze the fluorine-removing pyrolysis gas flow at 600°C for 3 minutes, and finally cool and store the pyrolysis gas. All organic components of the electrolyte are pyrolyzed and converted into gaseous products, which are convert...

Embodiment 3

[0036] A method for harmless and resourceful treatment of waste lithium battery electrolyte, comprising the following steps:

[0037] (1) Discharge 8 18650 waste lithium batteries to 0V under the conditions of waste lithium battery and conductive graphite powder mass ratio 1:1, stirring time 70min, stirring rate 110rpm / mim;

[0038] (2) Under nitrogen flow, the discharged waste lithium battery was heat-treated at 200° C. for 120 minutes, and 19.2 g of electrolyte solution was condensed and recovered.

[0039] (3) Pyrolyze the recovered electrolyte at 400°C for 8 minutes in a carbon dioxide atmosphere. After pyrolysis, use carbon dioxide gas flow to pass the pyrolysis gas through alumina powder at 400°C for defluorination treatment, and the weight of alumina powder increases by 0.45. g.

[0040] (4) Pyrolyze the fluorine-removing pyrolysis gas flow at 560°C for 4 minutes, and finally cool and store the pyrolysis gas. All organic components of the electrolyte are pyrolyzed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com