Process method of purifying and recycling mixed organic waste gas

A technology of organic waste gas and treatment methods, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of high operating costs, complicated processes, and low recovery efficiency, and achieve easy separation, recycling, and simple process routes , high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

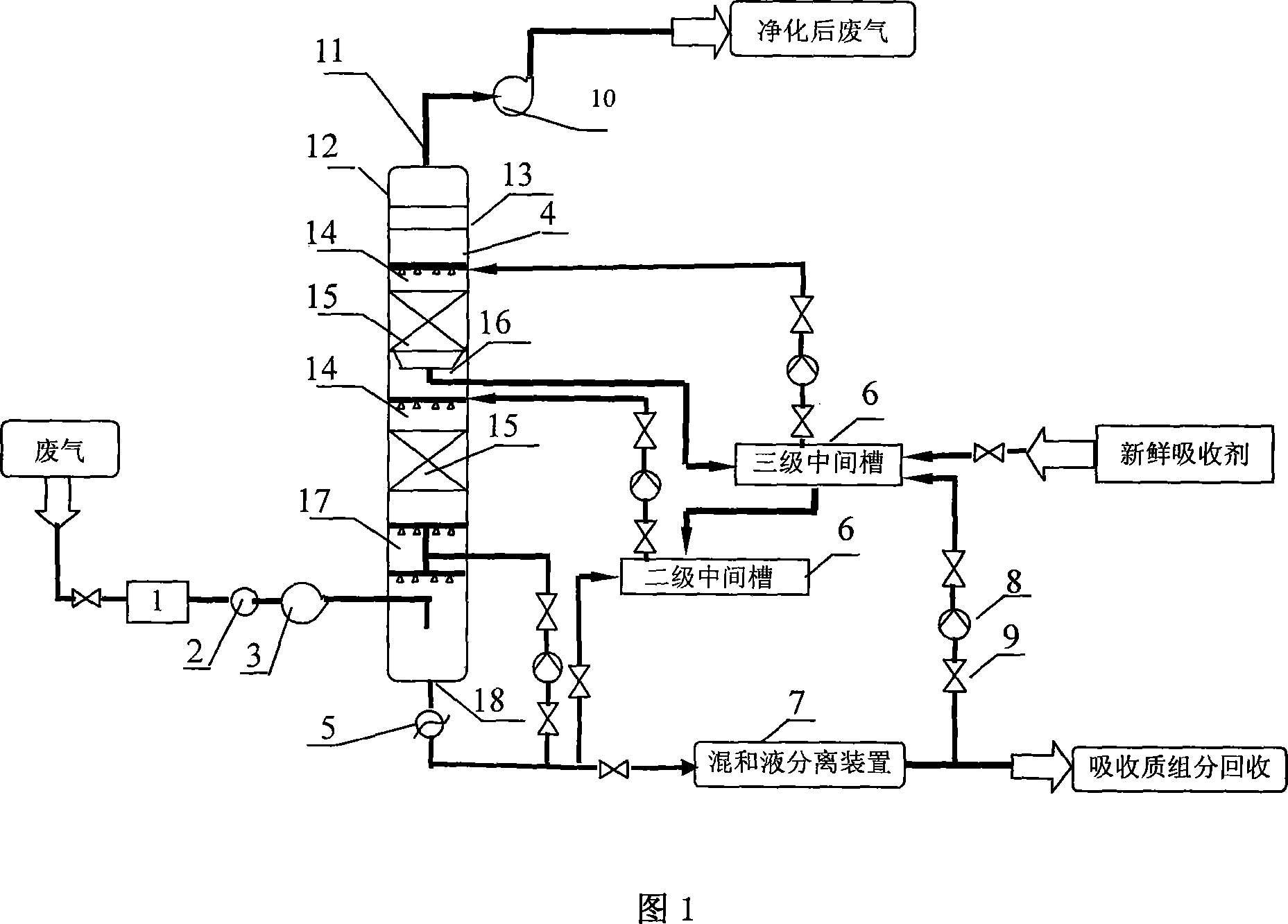

[0034] Example 1, the present invention is applied to the purification and recycling treatment of organic mixed waste gas from synthetic leather process. The exhaust gas mainly contains DMF, toluene, butanone, etc., and the total concentration of organic pollutants before treatment is 2000-8000mg / Nm 3 , which contains about 70% DMF and about 30% other organic pollutants such as toluene. The temperature of exhaust gas entering the tower is about 74°C, the main pollutants DMF and butanone are easily soluble in water, and toluene is hardly soluble in water.

[0035] The fresh absorbent pumped into the mixed waste gas absorption tower adopts dibutyl phthalate, and the absorption tower 4 is a three-stage absorption tower. According to the intake sequence of waste gas, except that the first stage of the treatment tower only has a spray layer 17, each of the other stages is composed of a packing layer 15 and a liquid distribution device 14. The packing layer 15 of the next stage and...

Embodiment 2

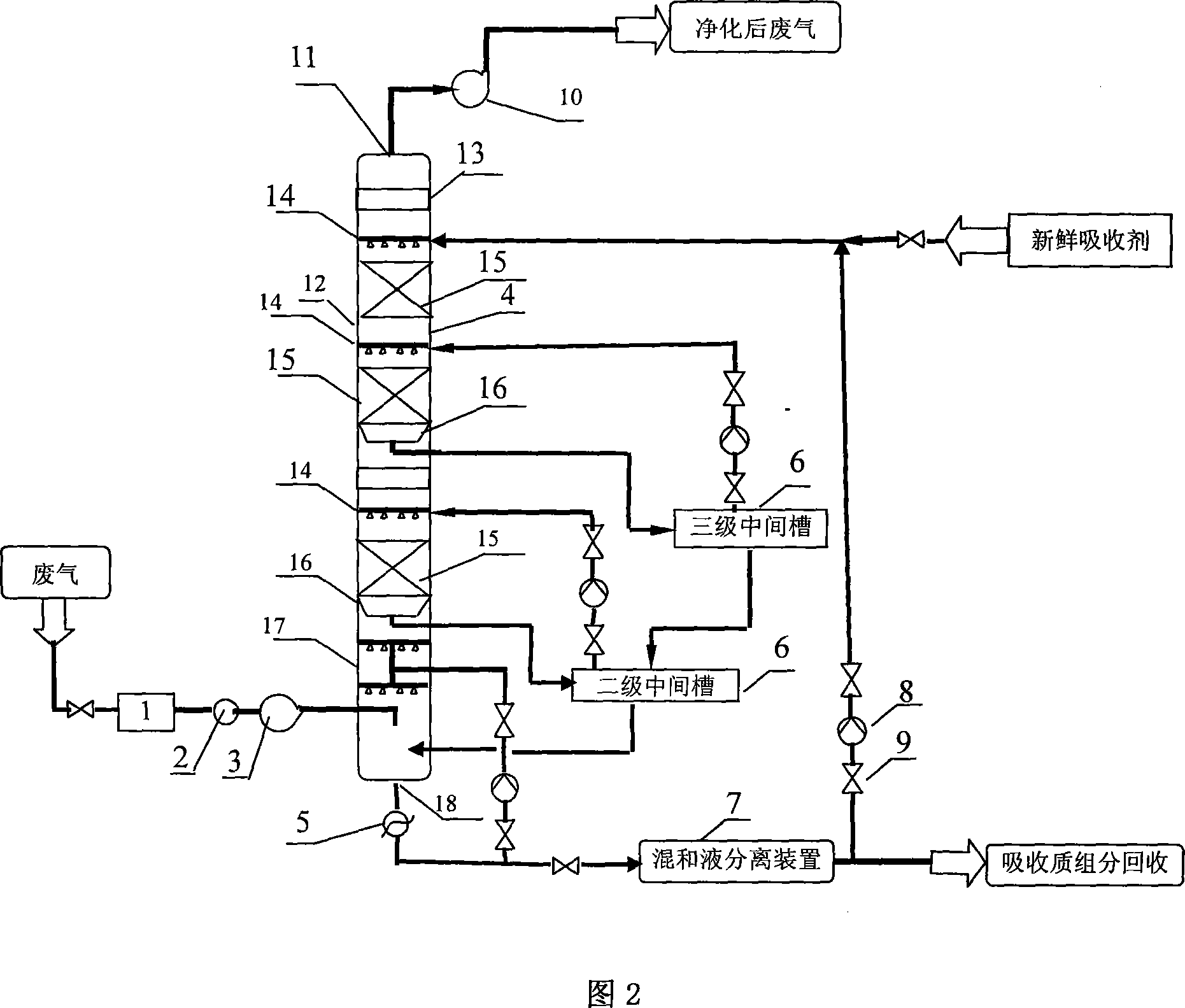

[0037] Embodiment 2, the present invention is applied to the purification and recycling treatment of organic mixed waste gas from synthetic leather process. The exhaust gas mainly contains DMF, toluene, butanone, etc., and the total concentration of organic pollutants before treatment is 2000-8000mg / Nm 3 , which contains about 70% DMF and about 30% other organic pollutants such as toluene. The exhaust gas temperature is about 74°C, the main pollutants DMF and butanone are easily soluble in water, and toluene is hardly soluble in water.

[0038] The fresh absorbent of the mixed exhaust gas absorption tower is dimethyl phthalate, and the absorption tower is a four-stage absorption tower. According to the intake sequence of waste gas, except that the first stage of the treatment tower only has a spray layer 17, each of the other stages is composed of a packing layer 15 and a liquid distribution device 14. The packing layer 15 of the next stage and the liquid of the previous stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com