Parifying and regenerating process for high and medium viscosity waste oils

A waste oil, high viscosity technology, applied in lubricating compositions and other directions, can solve the problems of economic waste, lack of treatment technology, environmental pollution, etc., and achieve the effects of recycling, improving economic benefits, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

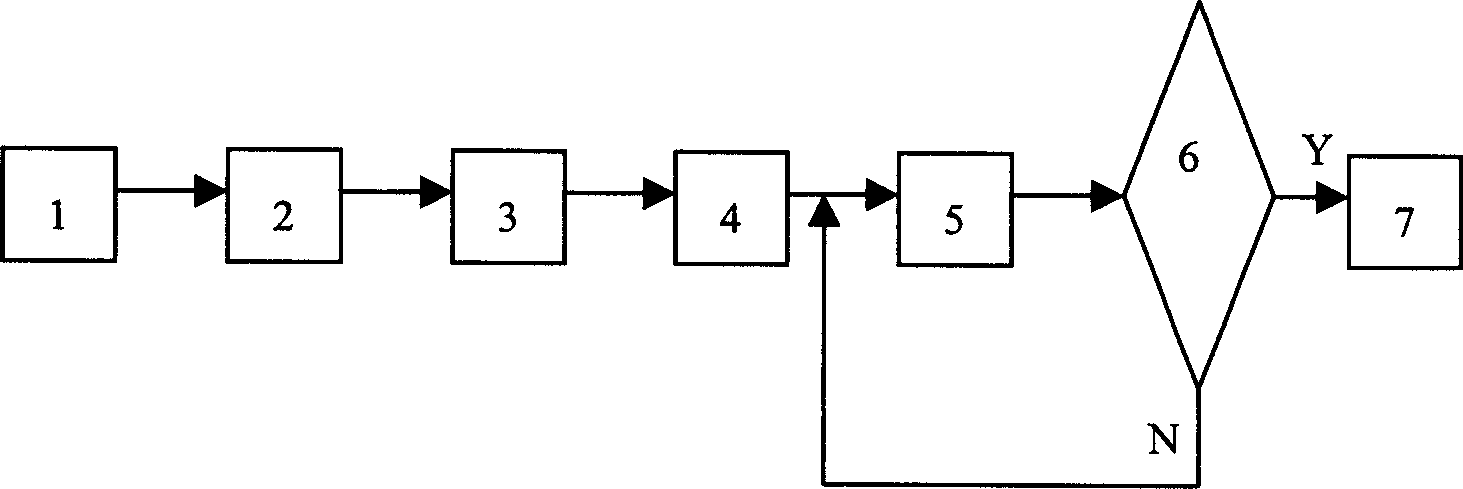

[0030] Purification and regeneration process flow of the present invention is as figure 1 shown.

[0031] Now the present invention will be further described in conjunction with an embodiment and a process flow diagram.

[0032] Box 1: Recycled used oil feedstock

[0033] The recovered waste oil referred to in the present invention refers to the recovered waste oil mixed with various high-viscosity lubricating oils, such as waste hydraulic oil, waste gear oil, waste bearing oil, etc., and their properties are quite different due to different recycling channels. The stock oil of the present invention is the waste oil that this enterprise reclaims, and its original data adopts the statistical value of the test data of all the waste oils that reclaim in a period of time, promptly is based on the lower limit of the average value, in production according to its actual situation The fluctuation range is adjusted.

[0034] The basic properties of the medium and high viscosity wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com