Oil-water separation fiber membrane

A technology of oil-water separation and fiber membrane, which is applied in the direction of filtration separation, fiber treatment, separation methods, etc., can solve the problems of less research on oil pollution, and achieve the effect of good dispersion effect, no agglomeration, and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

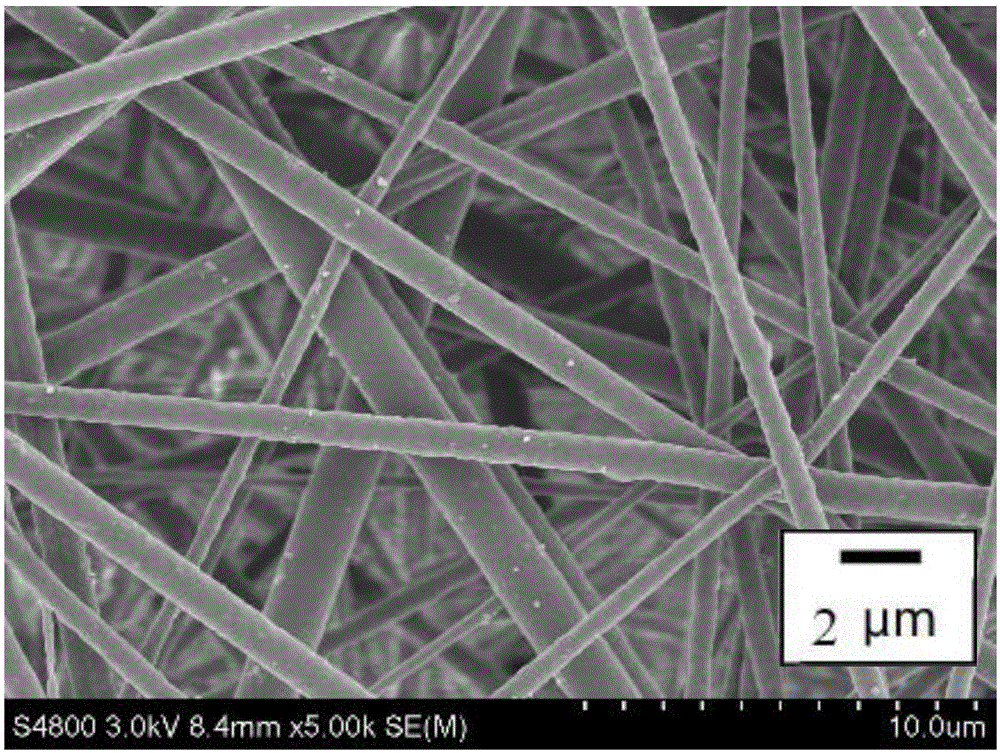

Embodiment 1

[0036] SiO 2 The nanopowder was placed in DMF, and it was ultrasonically treated with a cell ultrasonic pulverizer for 5 minutes to obtain SiO 2 Dispersion, SiO 2 SiO in dispersion 2 The mass fraction is 0.5%; add PSU particles into the dispersion liquid, and mechanically stir until it is completely dissolved to obtain a uniform and stable spinning solution, in which the PSU mass fraction is 15%; inject the spinning solution into parallel arrangement of multi-nozzle electrospinning machine to prepare PSU / SiO 2 Oil-water separation nanofiber membrane, the spinning process conditions are: spinning voltage 11kv, spinning distance 17cm, needle cylinder traverse distance 11cm, traverse speed 34cm / min, spinning speed 6m / min, spinning liquid flow rate 1ml / h.

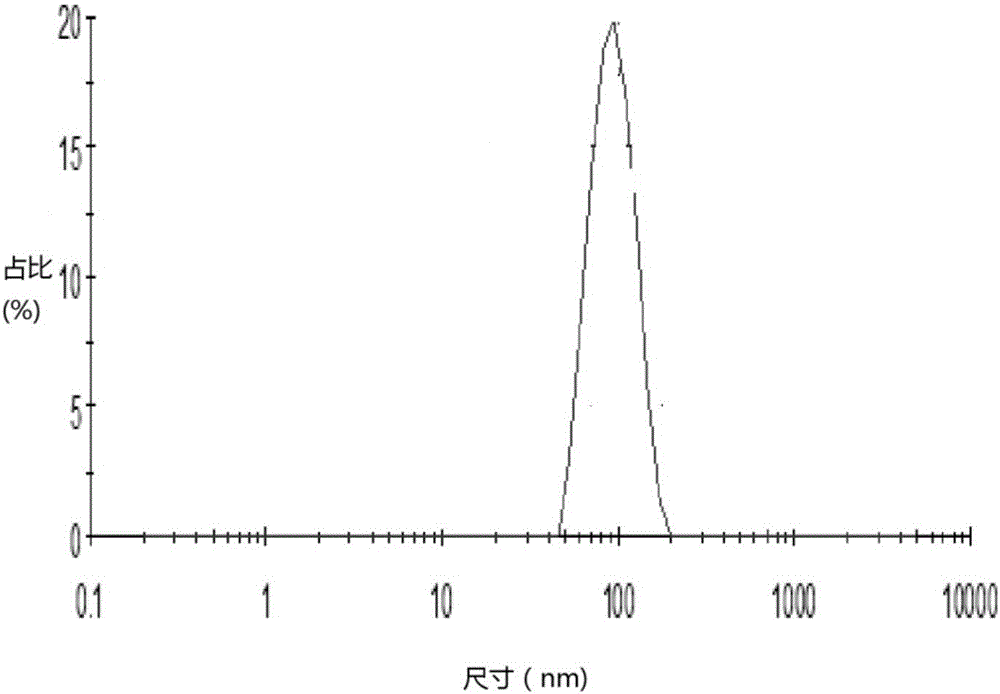

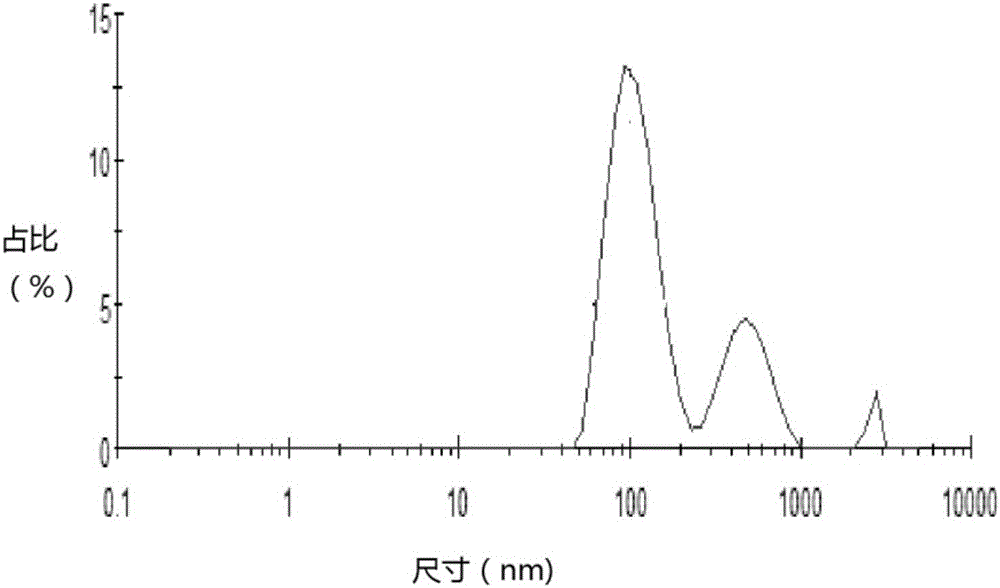

[0037] figure 1 It is SiO after crushing by cell ultrasonic pulverizer 2 Diameter distribution diagram, as can be seen from the figure, SiO 2 The particle size distribution is around 100nm, and the distribution range is...

Embodiment 2

[0043] SiO 2 The nanopowder was placed in DMF, and it was ultrasonically treated with a cell ultrasonic pulverizer for 5 minutes to obtain SiO 2 Dispersion, SiO 2 SiO in dispersion 2 The mass fraction is 1%; add PSU particles into the dispersion liquid, and mechanically stir until it is completely dissolved to obtain a uniform and stable spinning solution, in which the PSU mass fraction is 20%; inject the spinning solution into parallel multi-nozzle electrospinning machine to prepare PSU / SiO 2 Oil-water separation nanofiber membrane, the spinning process conditions are: spinning voltage 9kv, spinning distance 14cm, needle cylinder traverse distance 8cm, traverse speed 30cm / min, spinning speed 8m / min, spinning liquid flow rate 2ml / min h.

Embodiment 3

[0045] SiO 2 The nanopowder was placed in DMF, and it was ultrasonically treated with a cell ultrasonic pulverizer for 5 minutes to obtain SiO 2 Dispersion, SiO 2 SiO in dispersion 2 The mass fraction is 1.5%; add PSU particles into the dispersion liquid, and mechanically stir until it is completely dissolved to obtain a uniform and stable spinning solution, in which the PSU mass fraction is 20%; inject the spinning solution into parallel multi-nozzle electrospinning machine to prepare PSU / SiO 2 Oil-water separation nanofiber membrane, the spinning process conditions are: spinning voltage 9kv, spinning distance 14cm, needle cylinder traverse distance 10cm, traverse speed 34cm / min, spinning speed 6m / min, spinning liquid flow rate 1.5ml / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com