Co-extrusion molding composite board and preparation method thereof

A composite sheet and co-extrusion technology, applied in building components, thermal insulation, etc., can solve the problems of decreased ductility and impact resistance, brittle materials, low mechanical strength, etc., to reduce negative effects, ensure basic strength, and disperse heat. The effect of expansion and contraction stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Weigh raw materials:

[0059] Weigh the raw materials of wood-plastic frame 1: 40 parts by weight of polyvinyl chloride, 35 parts by weight of wood powder (wood powder, aspect ratio less than 40:1, particle diameter less than 1mm), 2.6 parts by weight of foaming agent, 10 parts by weight of inorganic filler Parts by weight, 8 parts by weight of impact modifier, 2 parts by weight of lubricant, 2 parts by weight of stabilizer, 2 parts by weight of compatibilizer, and 1 part by weight of processing aid.

[0060] Raw materials of the foam inner layer: 70 parts by weight of polystyrene, 10 parts by weight of flame retardant, 5 parts by weight of cell regulator, 3 parts by weight of modifier, 1 part by weight of processing aid and 5 parts by weight of chemical blowing agent , 6 parts by weight of inorganic reinforcing agent.

[0061] (2) Manufacturing process:

[0062] Firstly, prefabricate the perforated plate structure on the surface of metal plates such as steel plat...

Embodiment 2

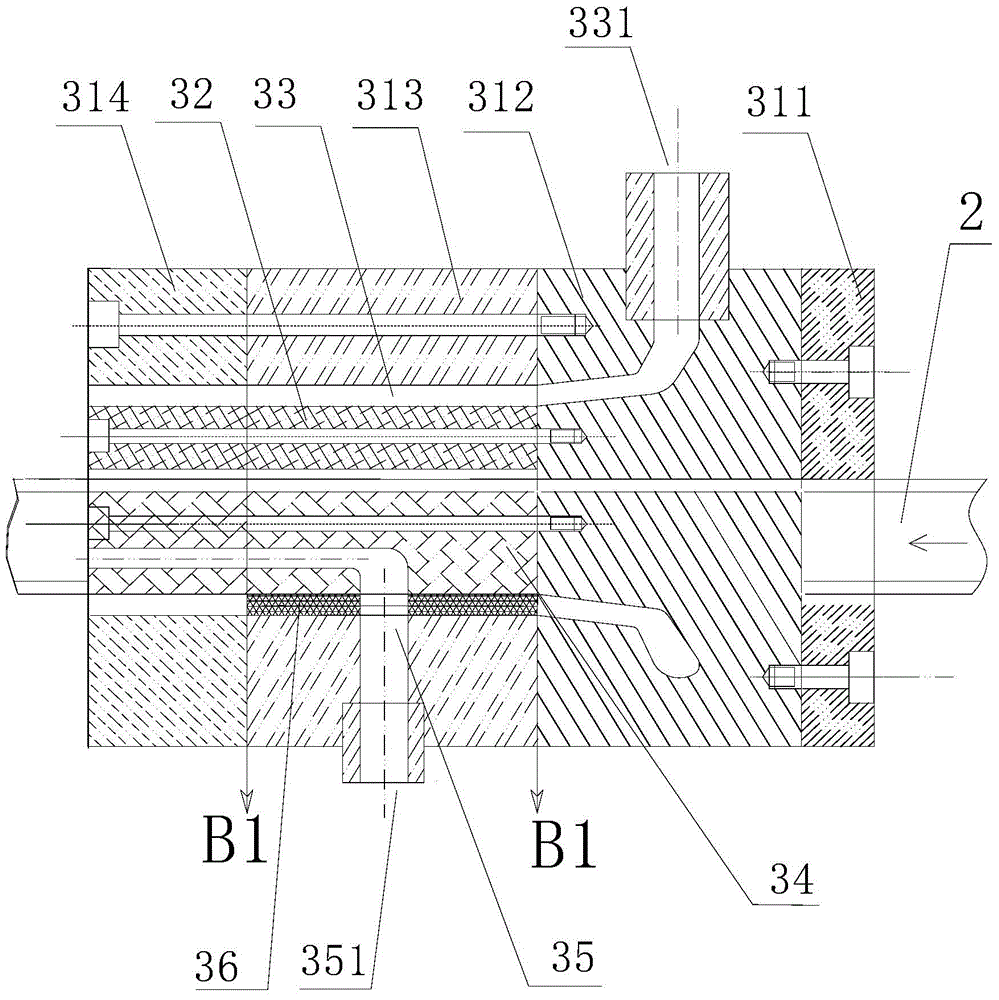

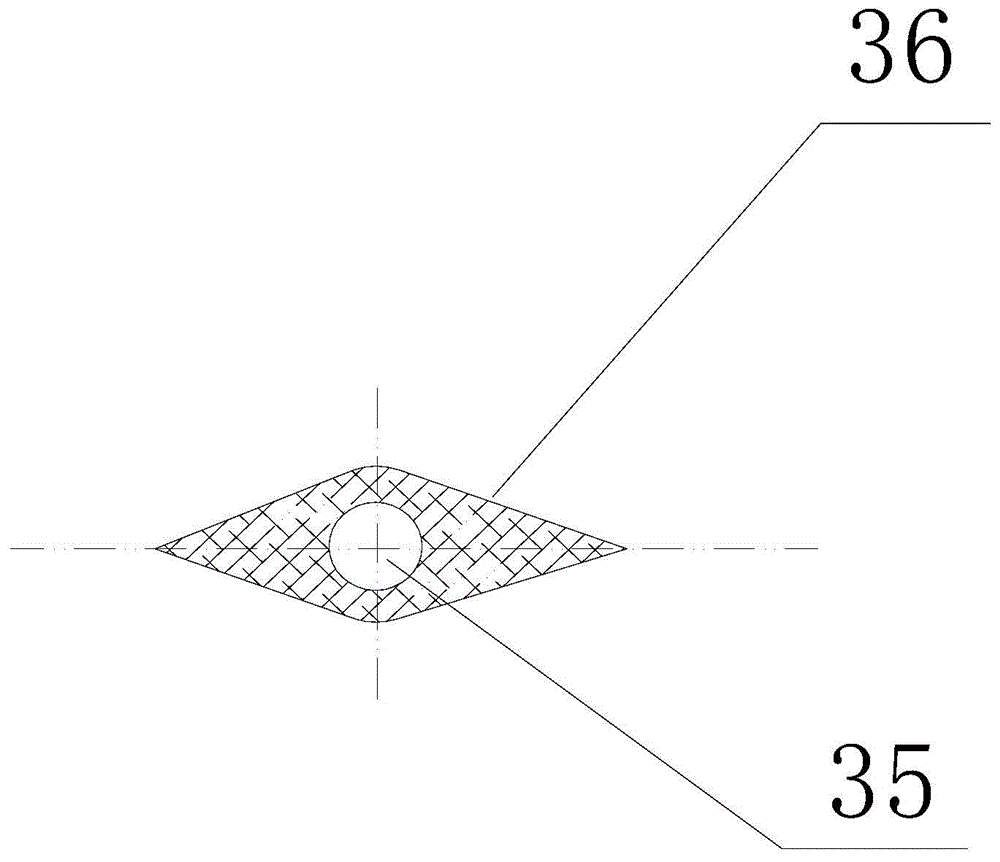

[0088] This embodiment produces as Figure 8 The preparation method and raw materials of the composite plate shown are basically the same as those in Example 1. The difference is that: using Figure 7 Extrusion die shown and as Figure 9 metal profiles shown. Figure 7 The metal profile 2 with figure 1 The position of the metal profile 2 in the composite panel is different, and the web of the metal profile 2 is bonded to the outer layer of the composite panel (the inner wall close to the surface of the composite panel) of the composite panel. Figure 7 and figure 1 The cross-sections at the same cutting position are basically the same, with only some differences in size.

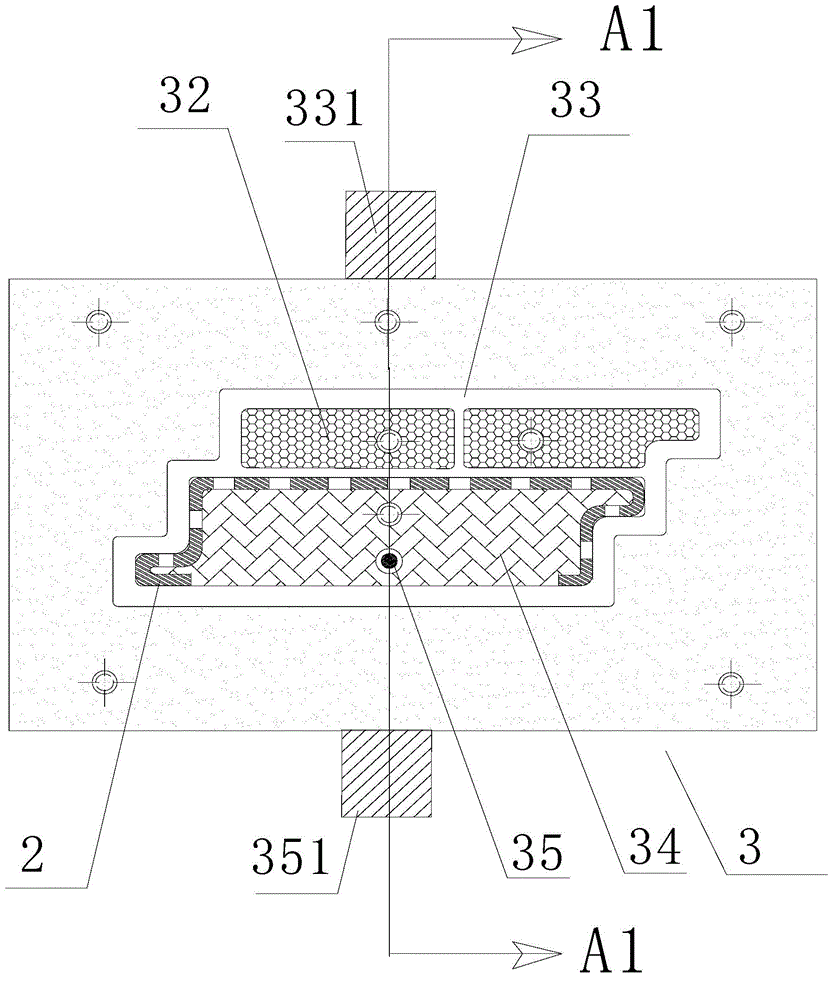

[0089] Extrusion die: Figure 7 Dies shown can be fabricated Figure 8 Composite panels as shown, such as Figure 7 As shown, the extrusion die 3 includes a first core 34 and three second cores 32 .

[0090] The first core 34 is provided with an external shape that matches the semi-open metal profil...

Embodiment 3

[0097] produce as Figure 10 Shown composite plate, its preparation method and raw material are basically the same as embodiment 2, difference is:

[0098] Extrusion die: the extrusion die 3 is only provided with the first core 34, and the second core 32 is not provided. The first core 34 is provided with an external shape that matches the semi-open metal profile 2, so that when the opening When the shaped metal profile 2 passes through the cavity 33, the open-shaped metal profile 2 is half-enclosed on the outside of the first mold core 34, and the metal profile 2 sent into the cavity 33 is entangled with the first core 34 to form a closed entity. . A gap for injecting molten wood-plastic material is provided between the airtight entity and the mold body 31. After the molten wood-plastic material enters the gap, a wood-plastic frame 1 of a composite plate is formed on the periphery of the sealed entity. After cooling and molding, the composite The board has only one specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com