A kind of preparation method of the composite sheet material that wood-plastic and metal profile co-extrude

A technology of metal profiles and composite panels, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of impossible co-extrusion of wood-plastic foamed materials and metal profiles, so as to improve the cooling and shaping efficiency and reduce the strength requirements , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Weigh raw materials:

[0050] Weigh the raw materials of wood-plastic frame 1: 40 parts by weight of polyvinyl chloride, 35 parts by weight of wood powder (wood powder, aspect ratio less than 40:1, particle diameter less than 1mm), 10 parts by weight of inorganic filler, impact modified 8 parts by weight of agent, 2 parts by weight of lubricant, 2 parts by weight of stabilizer, 2 parts by weight of compatibilizer, 1 part by weight of processing aid, and 3 parts by weight of foaming agent.

[0051] (2) Manufacturing process:

[0052] First of all, according to the section design and ventilation needs, it is processed into an open profile, wherein the cross section of the metal profile can be a U-shaped, C-shaped or semi-enclosed profiled shape. In this embodiment, such as Figure 5 Metal profile 2 shown.

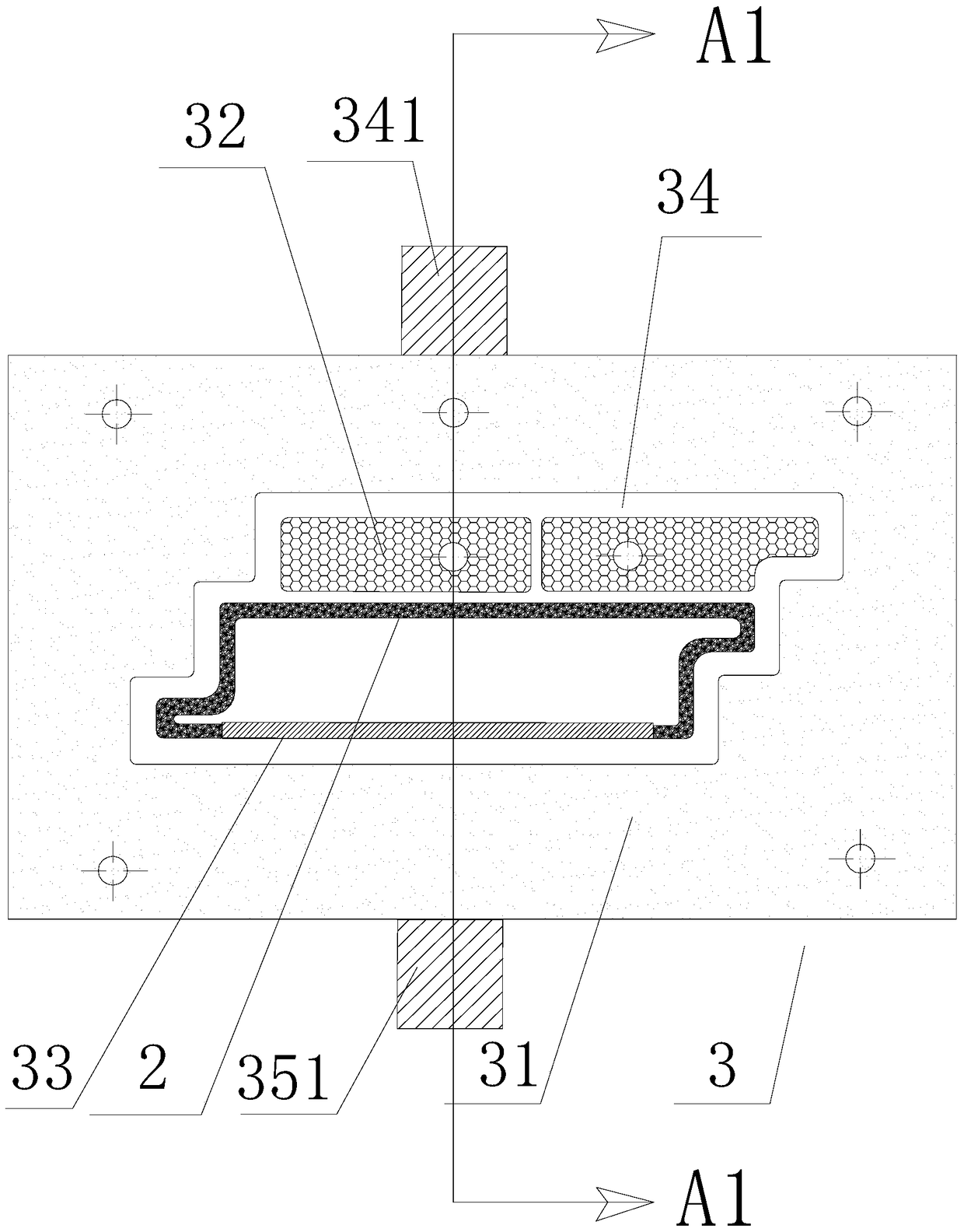

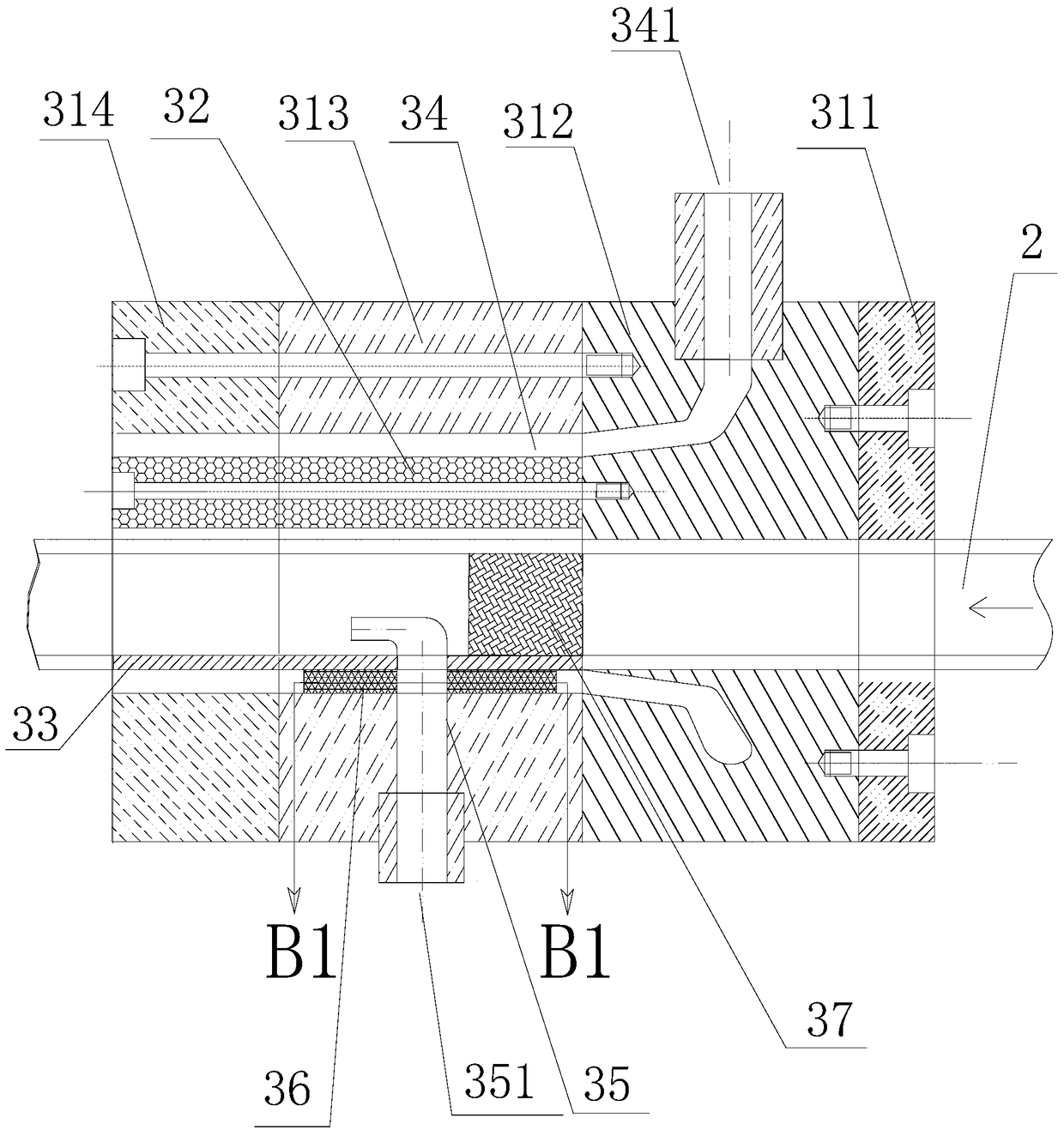

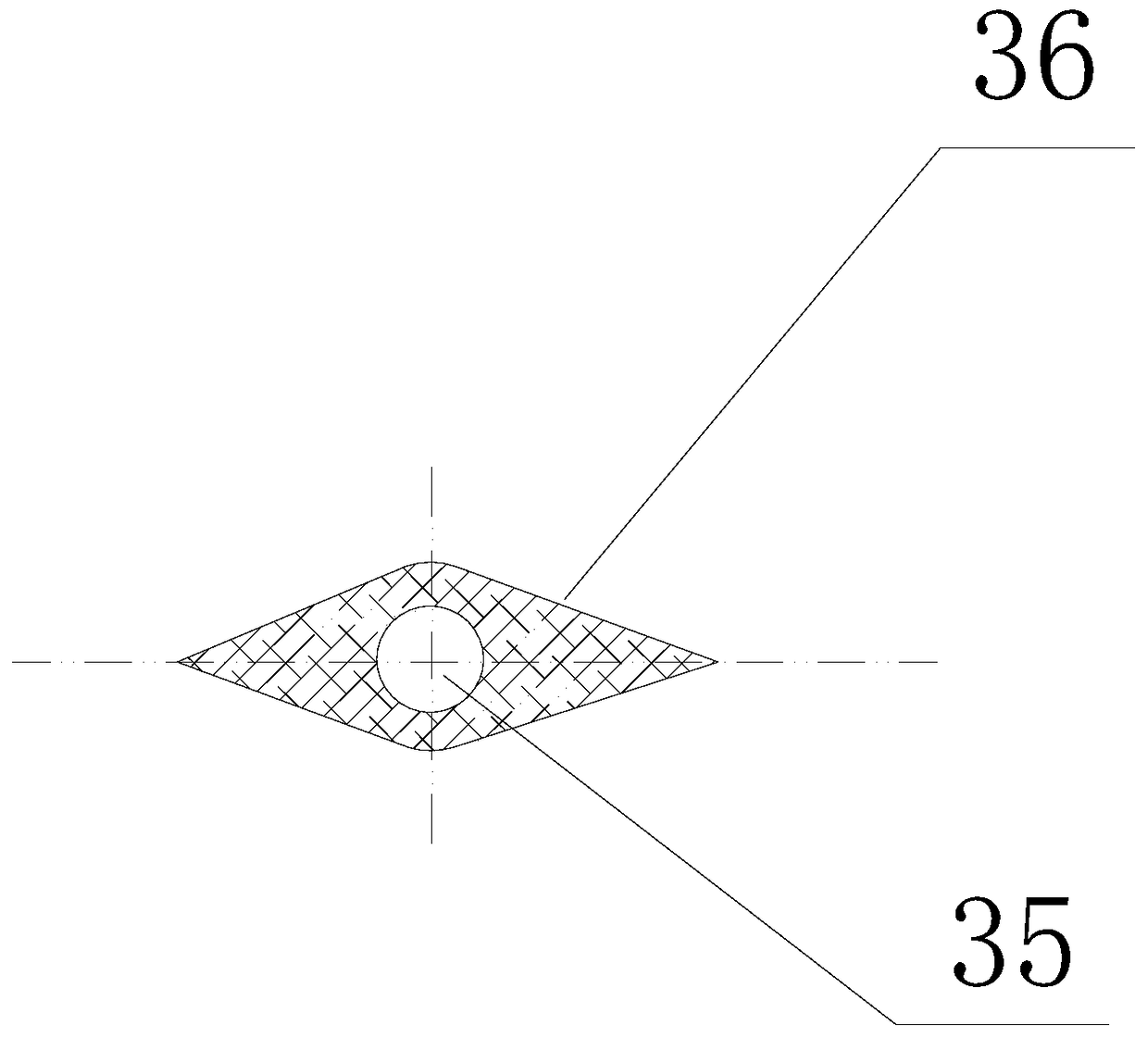

[0053] The composite sheet is co-extruded by an extrusion die 3 , the extrusion die 3 includes a die body 31 and a partition plate 33 , and the partition plate 3...

Embodiment 2

[0077] This embodiment produces as Figure 7 The preparation method and raw materials of the composite plate shown are basically the same as those in Example 1. The difference is that: using Figure 7 Extrusion dies and different metal profiles shown. Figure 6 The metal profiles 2 and divider panels 33 with figure 1 The positions of the metal profile 2 and the partition plate 33 in the composite plate are different, Figure 7 The web of the metal profile 2 in the composite panel is bonded to the outer layer of the composite panel (the inner wall close to the surface of the composite panel). Figure 7 and figure 1 The cross-sections at the same cutting position are basically the same, with only some differences in size.

[0078] Figure 6 Dies shown can be fabricated Figure 7 Composite panels as shown, such as Figure 6 As shown, the extrusion die 3 includes a partition plate 33 and three cores 32 .

[0079]Divider 33 and metal profile 2 surround a hollow container, ...

Embodiment 3

[0086] produce as Figure 9 Shown composite plate, its preparation method and raw material are basically the same as embodiment 2, difference is:

[0087] Extrusion die: The extrusion die 3 is only provided with a partition plate 33, but no core 32 is provided. In this way, when the composite sheet is manufactured, the partition plate 33 can form a hollow container with the metal profile 2, and the container and the mold body There is a gap for injecting molten wood-plastic material between 31, so that the molten wood-plastic foam material enters the cavity 34 and injects into the gap, forming a wood-plastic composite board on the periphery of the metal profile 2 and the partition plate 33. After the frame 1 is cooled and formed, the composite plate has only one first cavity, and the surface of the metal profile 2 is bonded to the wall of the first cavity.

[0088] Metal profile: this embodiment adopts Figure 9 The metal profile 2 is basically the same as the embodiment 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com