Low-temperature plasma modifying and microscale sizing integrated device for wood thin plates

A low-temperature plasma and micro-sizing technology, which is applied in the field of ion modification and micro-sizing integrated devices, can solve the problems of large consumption of adhesive, low formaldehyde emission, low production cost, etc., and achieves lower production costs. cost, improve product quality, reduce production costs and the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

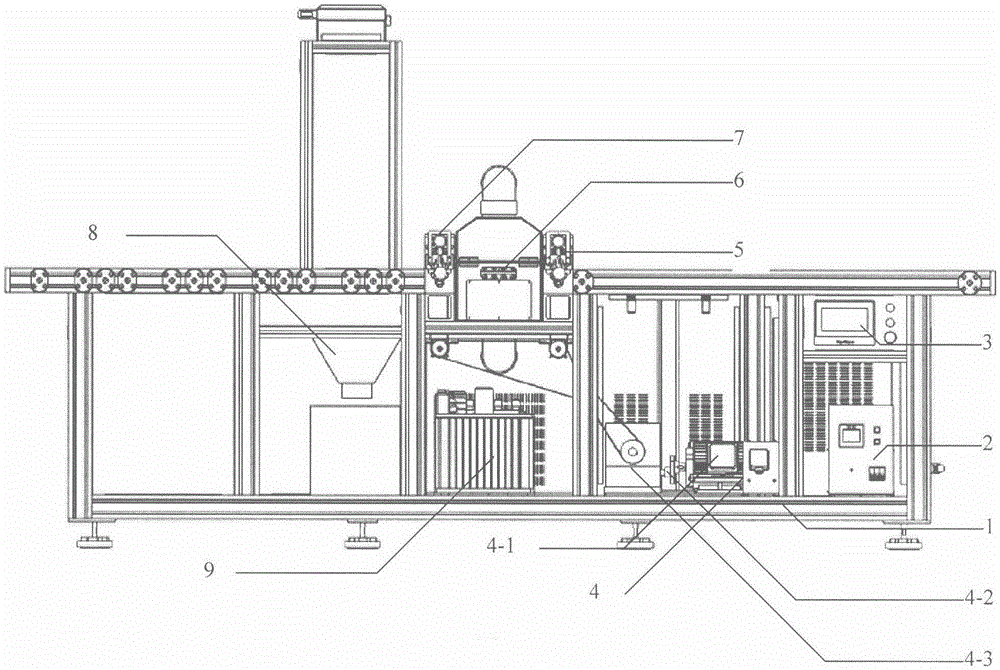

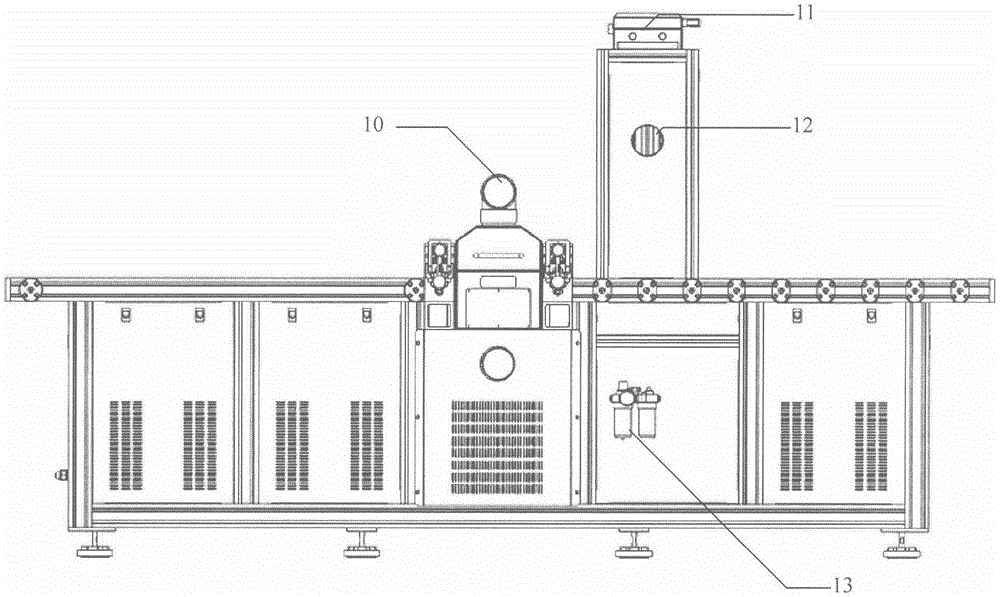

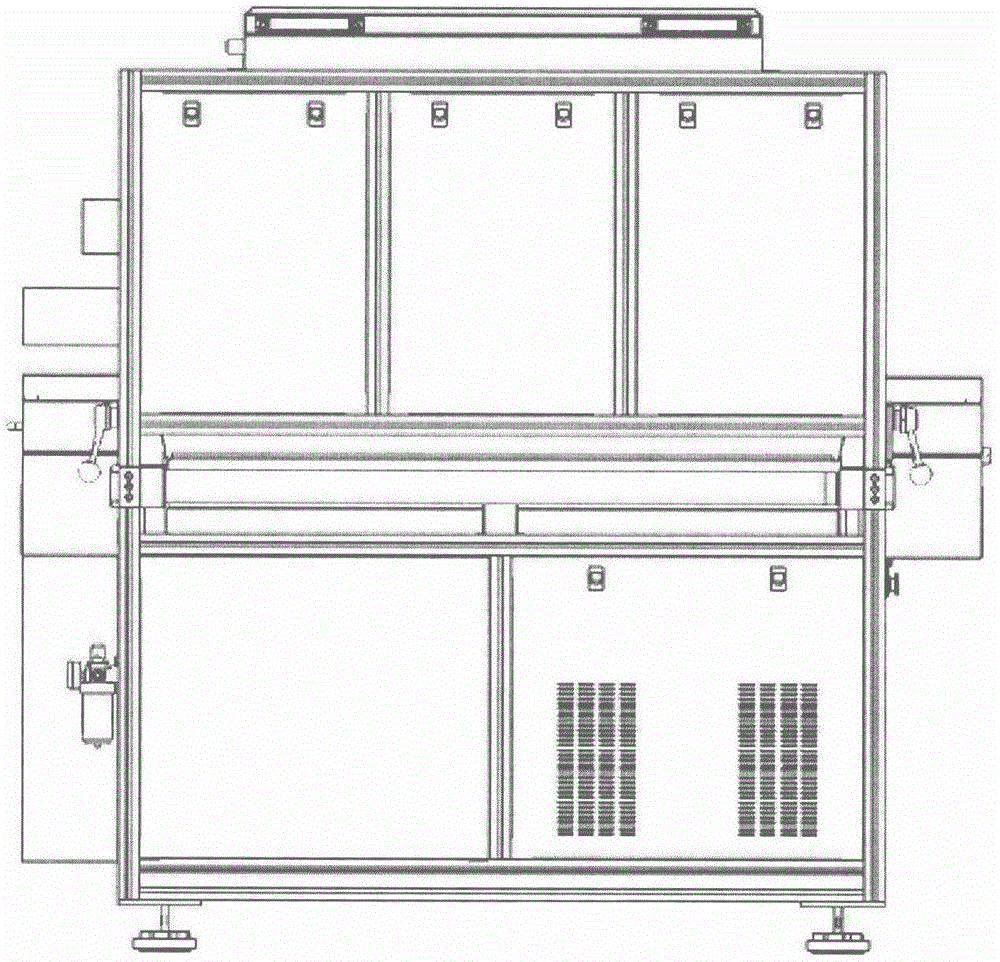

[0027] Control attached Figure 1-6 , the wood veneer low-temperature plasma modification and micro-glue integrated device includes an equipment frame, a wood veneer transmission component, a power component, a low-temperature plasma treatment component, an ultrasonic cyclone glue spray component and a controller component; wherein the wood veneer transmission component It includes a wooden veneer feeding conveyor belt 19, a wooden veneer feeding induction device 20, a wooden veneer feeding pressing roller 5, a wooden veneer discharging pressing roller 7, and a wooden veneer discharging induction device sequentially arranged on the equipment frame 1 along the feeding direction. The device 21 and the wood veneer discharge conveying roller group 22 are used to transport the wood veneer through the low-temperature plasma treatment assembly and the ultrasonic cyclone glue spray assembly; the power assembly is located below the wood veneer transmission assembly and is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com