Outdoor decorative film composition for plastic door window and preparation method of outdoor decorative film

A technology for plastic doors and windows and decorative films, which is applied in the field of outdoor decorative film composition and outdoor decorative film preparation, and can solve the problems of inability to detect the peel strength between the PMMA surface layer and the printing layer, poor weather resistance of PVC multilayer composite film, and PVC multilayer Composite film can not be used and other problems, to achieve the effect of promoting the use, high strength, high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

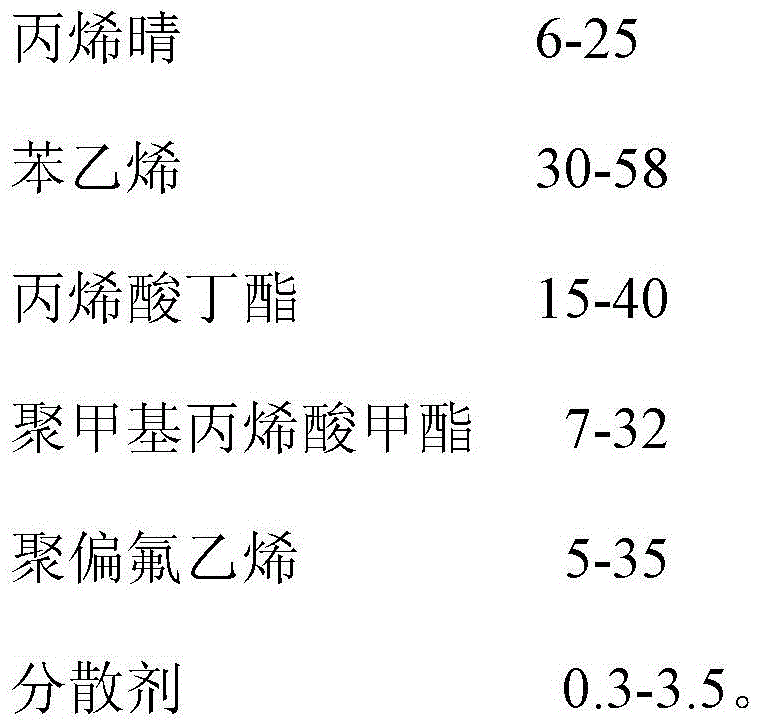

[0022] The outdoor decorative film composition for plastic doors and windows provided by the present embodiment includes the following raw materials by weight:

[0023]

[0024] The method of using the above composition to prepare an outdoor decorative film is as follows: weigh the raw materials in the above composition in proportion, put them into a high-speed mixer and mix them evenly, mix them at room temperature for 1.5-5 minutes, then put them into an extruder, double-roll open Plasticize in a mill or internal mixer, the plasticizing temperature is 150-250°C, and then put it into a calender to form a film, and then the calendered film is embossed by an embossing roller to form a concave-convex decorative pattern on the surface The outdoor decorative film is rolled up after cooling.

Embodiment 2

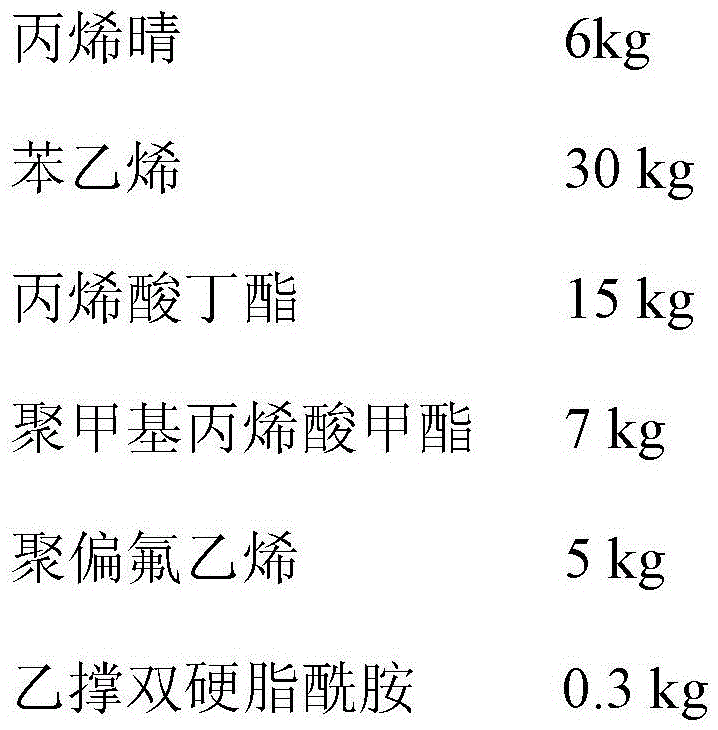

[0026] The outdoor decorative film composition for plastic doors and windows provided by the present embodiment includes the following raw materials by weight:

[0027]

[0028] The method for preparing an outdoor decorative film is the same as in Example 1.

Embodiment 3

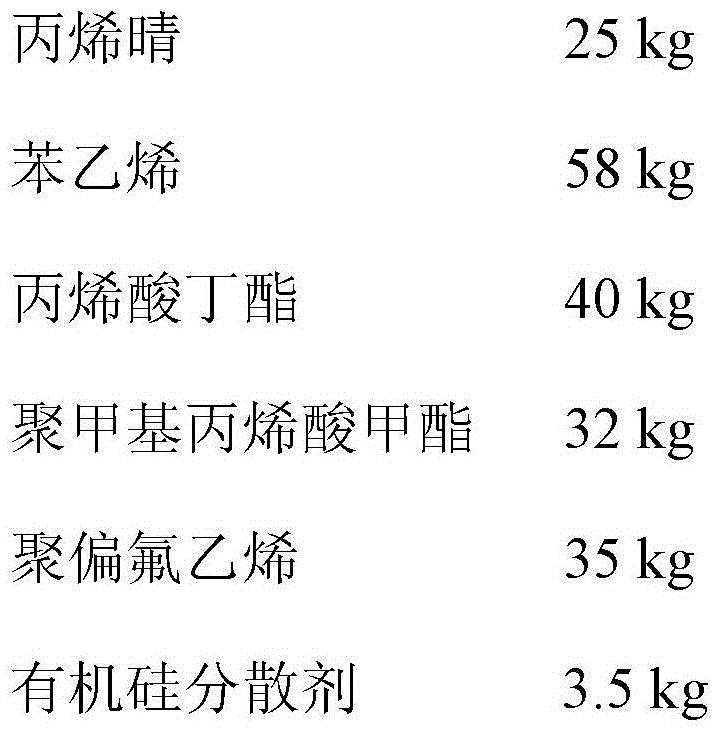

[0030] The outdoor decorative film composition for plastic doors and windows provided by the present embodiment includes the following raw materials by weight:

[0031]

[0032] The method for preparing an outdoor decorative film is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com