Dual-curing water-based coating as well as preparation method and construction process thereof

A water-based coating, dual-curing technology, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve problems such as high pollution and high VOC in oil-based coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

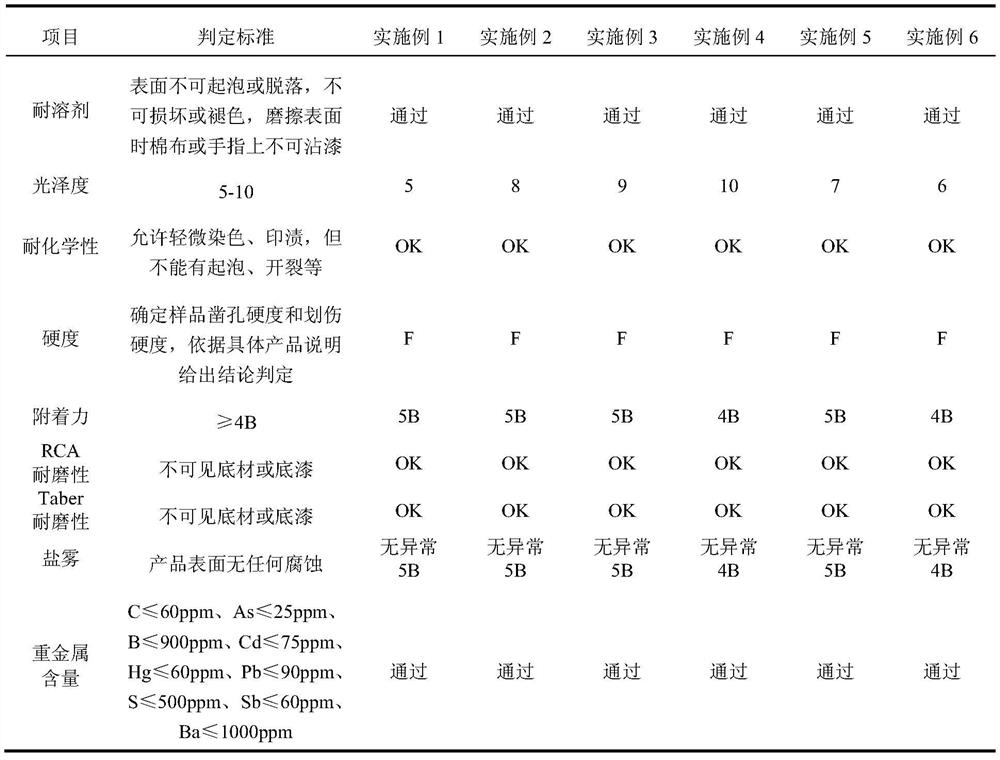

Examples

Embodiment 1~6

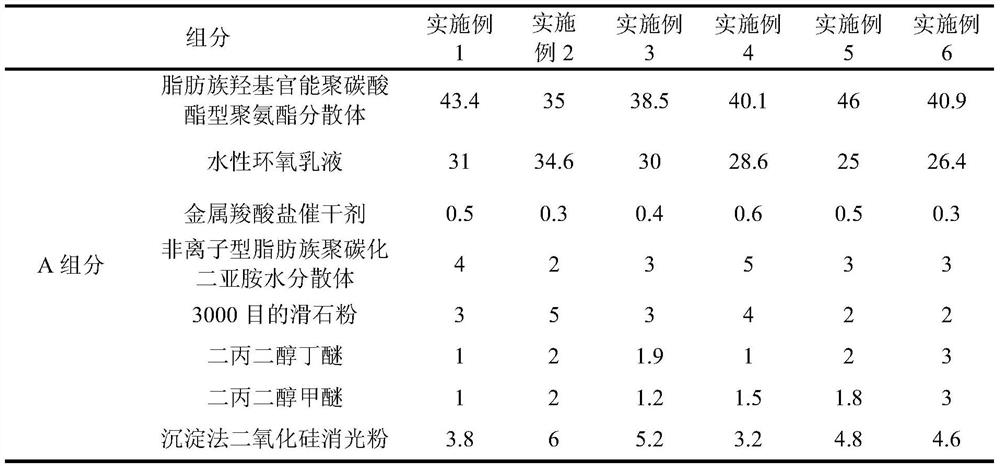

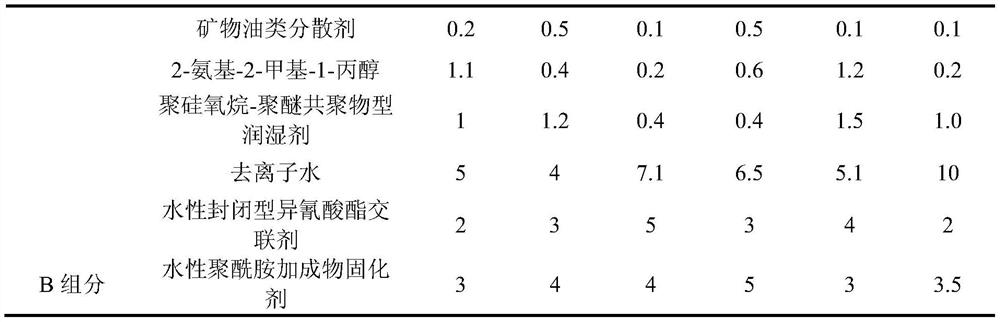

[0050] For the dual-curing water-based coatings of Examples 1-6, component A includes the following components in weight percent, which are listed in Table 1.

[0051] The defoaming agent is a mineral oil dispersant; the pH regulator is 2-amino-2-methyl-1-propanol; the wetting agent is a polysiloxane-polyether copolymer wetting agent.

[0052] The dual curing water-based coating formulation of table 1 embodiment 1~6

[0053]

[0054]

[0055] According to the formulation dosage of the specific examples in Table 1, weigh aliphatic hydroxyl functional polycarbonate polyurethane dispersion, metal carboxylate drier, 3000 mesh talcum powder, precipitated silica matting powder, polysiloxane Mix alkane-polyether copolymer wetting agent and mineral oil dispersant, stir evenly, and disperse at 2000rpm for 20min until the fineness is less than 20μm;

[0056] Then add water-based epoxy emulsion, non-ionic aliphatic polycarbodiimide aqueous dispersion, water-based blocked isocyanat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com