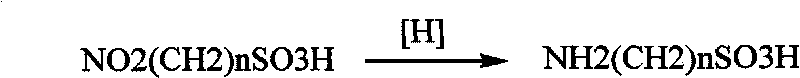

Preparation method of amino-substituted hydrocarbyl sulfonic acid

A technology of hydrocarbyl sulfonic acid and amino group, which is applied in the field of preparation of amino-substituted hydrocarbyl sulfonic acid, can solve problems such as not reaching an ideal state, and achieve the effects of improving production environment, short reaction time and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In a 1L autoclave with magnetic stirring, heating, and pressurization system, add 200g (1.52mol) of sodium sulfite with a content of 96% and 205g (1.38mol) of amino alcohol sulfate with a content of 95%, and then fill it with water, seal it, and magnetically Stir. Increase the pressure in the kettle to about 5Mpa by adding water pressure through a high-pressure pump, and quickly heat it to about 180°C. After reacting for 2 hours, stop stirring, concentrate while it is hot, remove Glauber's salt, cool the mother liquor to 32°C to crystallize, and filter to obtain Taurine crude product 142g.

[0028] Put 142g of the above-mentioned crude taurine into a 500ml four-necked reaction flask, add 220ml of pure water, heat to 85°C to completely dissolve the crude taurine, add 0.6g of activated carbon, stir for half an hour, remove the activated carbon by filtration, and cool down Crystallize at 8°C. After separation by filtration, washing and drying, 114 g (0.91 mol) of taurine...

Embodiment 2

[0030] In a 1L autoclave with magnetic stirring, heating, and pressurization system, add 335 g (2.42 mol) of ammonium sulfite with a content of 84% and 300 g (2.02 mol) of amino alcohol sulfate with a content of 95%, and then fill up with water , sealed, and magnetically stirred. Increase the pressure in the kettle to about 8Mpa by adding water pressure through a high-pressure pump, and quickly heat it to about 220°C. After reacting for 0.5 hours, stop stirring, concentrate part of the water while it is hot, cool down to 5°C to crystallize, and obtain taurine after filtration. Crude product 203.6g.

[0031] Put the crude taurine above into a 1000ml four-necked reaction flask, add 400ml of pure water, heat to 85°C to completely dissolve the crude taurine, add 1g of activated carbon, stir for half an hour, remove the activated carbon by filtration, and cool down to 85°C. ℃ crystallization. After separation by filtration, washing and drying, 179 g (1.43 mol) of taurine refined ...

Embodiment 3

[0033] In the autoclave of 1L band magnetic stirring, heating, pressurization system, add content and be that 96% sodium sulfite 169g (1.29mol) and content are 200g (1.21mol) of 94% 3-amino propanol sulfate and be full of water again, Seal and stir magnetically. Increase the pressure in the kettle to about 5Mpa by adding water pressure through a high-pressure pump, and quickly heat it to about 180°C. After reacting for 2 hours, stop stirring, concentrate while it is hot, remove Glauber's salt, cool the mother liquor to 32°C to crystallize, and filter to obtain The crude product of aminopropanesulfonic acid was 139g.

[0034] Put 139g of the crude product of aminopropanesulfonic acid into a 500ml four-necked reaction flask, add 200ml of pure water, heat to 85°C to completely dissolve the crude aminopropanesulfonic acid, add 0.55g of activated carbon, stir for half an hour, and filter to remove the activated carbon , cooled to 8°C for crystallization. After separation by filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com