165-steel-grade drill rod weld joint heat treatment method

A heat treatment method and drill pipe technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of uneven impact toughness of welds, high hardness of the welded pipe body side, and large fluctuations in impact value, and achieve a good comprehensive Mechanical properties, uniformity of structure, effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following description.

[0016] An embodiment of a heat treatment method for a 165 steel grade drill pipe weld seam in the present invention includes: step 1-quenching, step 2-first tempering and step 3-second tempering.

[0017] The specific steps and parameters of step 1-quenching are as follows:

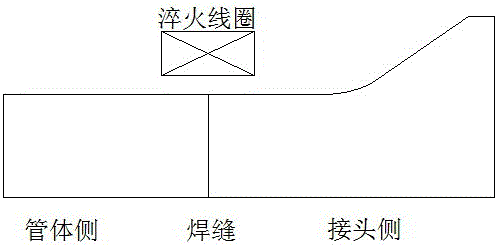

[0018] (1) Send the welding area of the drill pipe to the position of the quenching coil, and align the weld seam with the center position of the quenching coil, such as figure 1 shown;

[0019] (2) Use 35-40 seconds to raise the temperature of the welding zone to 925-935°C and keep it warm for 85-95 seconds;

[0020] (3) Compressed air quenching, the inner and outer surfaces of the weld are quenched with compressed air, and the outlet pressure of quenching air is ≥...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com