Polybutadiene rubber and preparation method thereof

A technology for polybutadiene rubber and butadiene, which is applied in the field of polybutadiene rubber and its preparation, can solve the problems of high quality requirements, complicated process control, inability to prepare basic molecular weight polymers, etc. The effect of control and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the polybutadiene rubber in the present invention also includes removing the organic solvent after contacting the copolymer solution with the terminator. The methods for removing the organic solvent are well known to those skilled in the art, and will not be repeated here. In order to obtain polybutadiene rubber with more excellent aging resistance, preferably, the preparation method of the polybutadiene rubber also includes contacting the copolymer solution with a terminator and before removing the organic solvent, The chemical solution is in contact with the anti-aging agent. The amount of the anti-aging agent can generally be 0.1-2% by weight of the content of the polybutadiene rubber. The anti-aging agent can be various existing anti-aging agents that can be used as polybutadiene rubber additives, for example, the anti-aging agent can be phenolic and / or amine anti-aging agents, preferably selected from 2,6-ditertiary One of butyl p-cresol...

Embodiment 1

[0039] This embodiment is used to illustrate the preparation method of the polybutadiene rubber provided by the present invention.

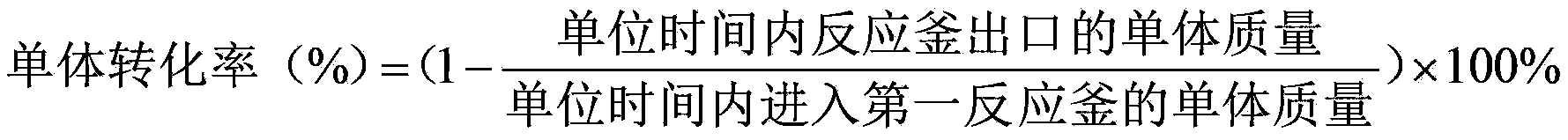

[0040] The reaction was carried out in two 5-liter polymerization reactors connected in series. Under the protective atmosphere of high-purity nitrogen, the residence time of the materials in the single tank is 30 minutes, and the pressure in the polymerization tank is controlled at 0.7 MPa (gauge pressure). The feed rate of various reaction materials is: mixed solvent (cyclohexane and n-hexane, weight ratio 88:12) 6199g / h, 1,3-butadiene 1361g / h, n-butyllithium 1.09g / h and 1,2-butadiene 0.68g / h. Control the polymerization reaction temperature of the first kettle to 100±2°C, and the polymerization reaction temperature of the second kettle to 125±2℃, add a terminator isopropanol 1.02g / h to the outlet of the second kettle to terminate the reaction, and add 0.2% of monomer weight to prevent aging Agent Irganox1520 to obtain polybutadiene rubber glu...

Embodiment 2

[0042] This example is used to illustrate the preparation method of polybutadiene rubber provided by the present invention.

[0043] Using the same experimental conditions as in Example 1, the only difference is that the amount of 1,2-butadiene added is 0.41 g / h. The monomer conversion and the molecular parameters and gel content of polybutadiene rubber are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com