Alloy ductile iron crankshaft and heat treatment process thereof

A technology of alloy balls and crankshafts, which is applied in the fields of metallurgy and cast iron alloys, can solve problems such as the unsatisfactory fillet rolling effect, difficult processing of ADI crankshafts, and low tensile strength, so as to improve the spheroidization effect, improve the inoculation quality, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Using 100% carbon structural steel, electric furnace smelting, in the electric furnace smelting process, first add the recarburizer, the addition amount is 3.4%, and the 15T electric furnace is about 510Kg, which is added in 3 batches, which is beneficial The absorption of C, and then adding 1.4% of 75 ferrosilicon for inoculation, it is about 21Kg calculated by 15T electric furnace, after spheroidizing treatment, casting molding. During the pouring process, the second inoculation with the flow is carried out. The obtained alloy ductile iron crankshaft composition (weight %) is: C 3.50, Si 1.60, Mn 0.31, P 0.024, S 0.018, Cr 0.03, Cu 0.22, Mg 0.043, Ti 0.0093, and the balance is Fe. The crankshaft after casting is heat-treated in accordance with the following conditions: 840°C for 2.5 hours, cooling to 770°C with the furnace for 3 hours, and strong wind and mist cooling from the furnace.

Embodiment 2

[0015] Example 2: Using 100% carbon structural steel, electric furnace smelting, first add recarburizer during the electric furnace smelting process, the addition amount is 3.7%, and the 15T electric furnace is about 555Kg, which is added in 3 batches, which is beneficial The absorption of C is inoculated by adding 1.8% of 75 ferrosilicon, calculated by a 15T electric furnace, at about 27Kg, after spheroidizing treatment, and casting. During the pouring process, the second inoculation with the flow is carried out. The obtained alloy ductile iron crankshaft composition (weight%) is: C 3.83, Si 2.14, Mn 0.45, P 0.020, S 0.0072, Cr 0.051, Cu 0.35, Mg 0.041, Ti 0.010, and the balance is Fe. The crankshaft after casting is heat-treated according to the following conditions: 880 degrees Celsius heat preservation for 1.5 hours, followed by furnace cooling to 810 degrees Celsius heat preservation for 2 hours, out of the furnace strong wind mist cooling.

Embodiment 3

[0016] Example 3: Using 100% carbon structural steel electric furnace smelting, in the electric furnace smelting process, first add the recarburizer, the addition amount is about 3.9%, and the 15T electric furnace is about 585Kg, which is added in 3 batches. Conducive to the absorption of C, it is inoculated by adding about 2.3% of 75 ferrosilicon, calculated with a 15T electric furnace, about 34.5Kg, after spheroidizing treatment, and finally inoculated and molded with the flow. The obtained alloy ductile iron crankshaft composition (weight%) is: C 3.99, Si 2.48, Mn 0.9, P 0.039, S 0.012, Cr 0.068, Cu 0.48, Mg 0.074, Ti 0.017, and the balance is Fe. The crankshaft after casting is heat-treated according to the following conditions: heat preservation at 920°C for 2.5 hours, heat preservation with furnace cooling to 850°C for 2.5 hours, and strong wind and mist cooling out of the furnace. An alloy ductile iron crankshaft is obtained.

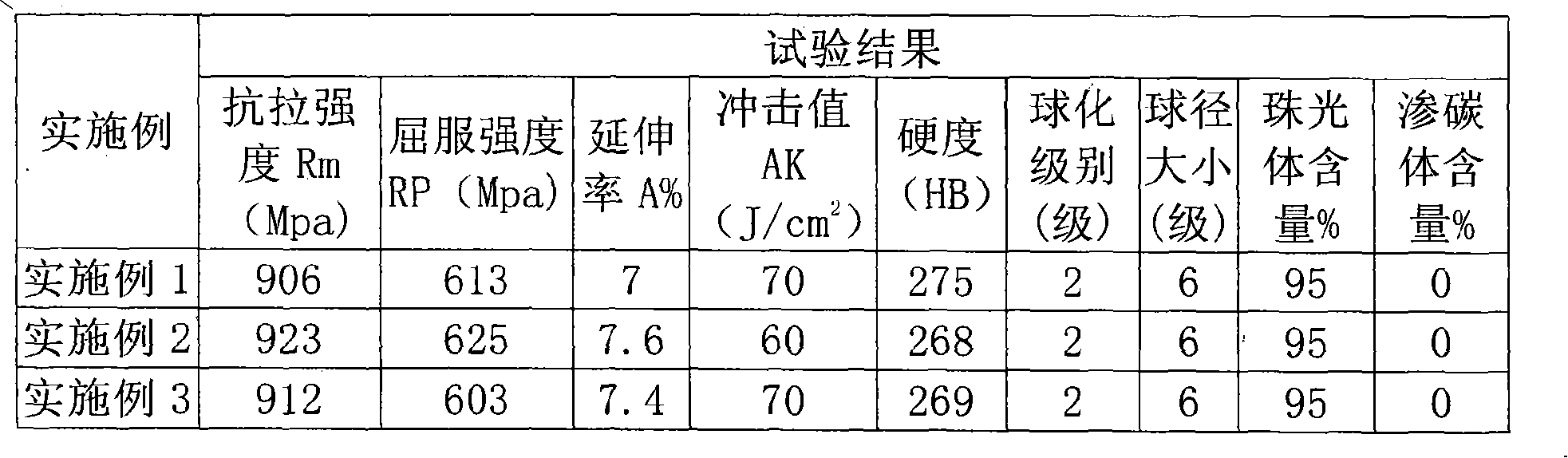

[0017] The specific performance indexes of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com