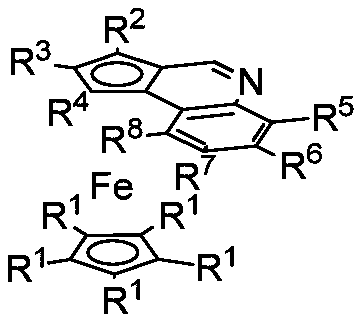

A class of ferrocenoquinoline compounds with face chirality and its synthesis method

A chiral ferrocene and compound technology, applied in chemical instruments and methods, organic chemistry, metallocene and other directions, to achieve the effect of less reaction steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

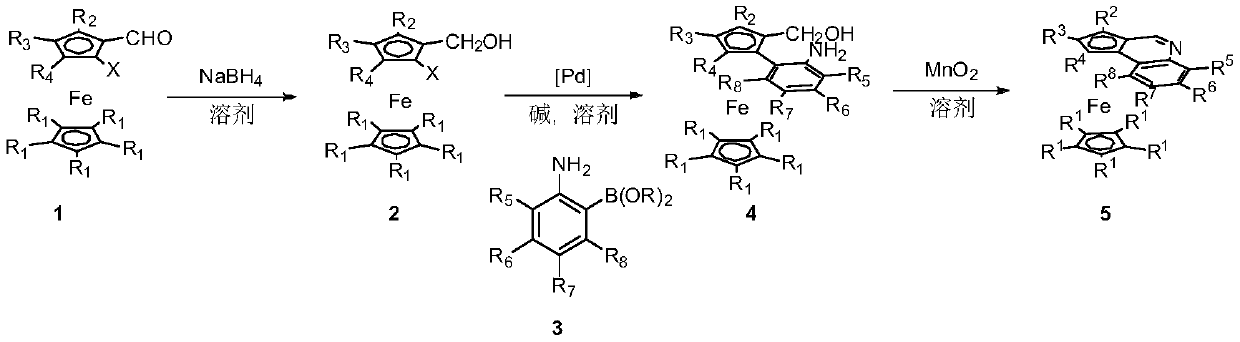

Method used

Image

Examples

Embodiment 1

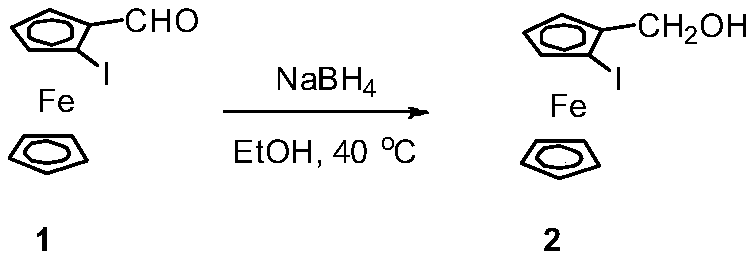

[0031] The synthesis of embodiment 1 compound 2

[0032]

[0033] Under nitrogen protection, add compound 1 (1.049g, 3.1mmol) and 10mL EtOH to a 100mL reaction flask, raise the temperature to 40°C, and slowly add NaBH 4 (176mg, 4.5mmol), stirred overnight. Add 10mL H 2 O quenches the reaction. Dichloromethane extraction, anhydrous Na 2 SO 4 After drying, column chromatography gave 0.960 g of a light yellow solid with a yield of 91%.

Embodiment 2

[0034] The synthesis of embodiment 2 compound 4a

[0035]

[0036] Under nitrogen protection, compound 2 (260mg, 0.76mmol), compound 3a (230mmg, 1.52mmol), Pd(OAc) were added to the 50mL reaction flask 2 (34mg, 0.152mmol), Ba(OH) 2 ·8H 2 O (480 mg, 1.52 mmol), 10 mL ethanol and 1 mL water. Raise the temperature to 100°C and react overnight. Cool to room temperature, add 20mL H 2 O, dichloromethane extraction, anhydrous Na 2 SO 4 Drying and column chromatography gave 0.170 g of a light yellow solid with a yield of 73%. 1 H NMR (400MHz, CDCl 3 )δ7.67(dd, J=7.6,1.5Hz,1H),7.18-7.12(m,1H),6.92-6.86(m,1H),6.72(dd,J=7.9,0.8Hz,1H),4.46 (t,J=6.5,5.1Hz,1H),4.30-4.27(m,3H),4.23(s,5H),3.76(s,2H); 13 C NMR (100MHz, CDCl 3 )δ144.6, 133.0, 128.3, 123.2, 119.5, 116.1, 87.7, 85.9, 71.0, 69.6, 69.5, 67.6, 59.9. HRMS: Calculated for C 17 h 17 56 FeNONa[M+Na] + 330.0557,found 330.0555.

Embodiment 3

[0037] The synthesis of embodiment 3 compound 4b

[0038]

[0039] Under nitrogen protection, compound 2 (260mg, 0.76mmol), compound 3b (254mmg, 1.52mmol), Pd(OAc) were added to the 50mL reaction flask 2 (34mg, 0.152mmol), Ba(OH) 2 ·8H 2 O (480 mg, 1.52 mmol), 10 mL ethanol and 1 mL water. Raise the temperature to 100°C and react overnight. Cool to room temperature, add 20mL H 2 O, dichloromethane extraction, anhydrous Na 2 SO 4 After drying, column chromatography gave 0.186 g of a light yellow solid with a yield of 73%. 1 H NMR (400MHz, CDCl 3 )δ7.57 (d, J = 8.4Hz, 1H), 6.46 (dd, J = 8.4, 2.4Hz, 1H), 6.28 (d, J = 2.4Hz, 1H), 4.46 (s, 1H), 4.31- 4.25(m,3H),4.25-4.19(m,6H),3.80(s,3H),3.64(brs,3H); 13 C NMR (100MHz, CDCl 3)δ160.0, 145.8, 133.8, 115.4, 104.9, 101.7, 87.5, 86.4, 70.8, 69.5, 67.5, 60.0, 55.3. HRMS Calculated for C 18 h 19 56 FeNO 2 Na[M+Na] + 360.0663,found 360.0656.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com