Preparation method of graphene polyaniline aerogel thermoelectric material

A thermoelectric material, polyaniline technology, applied in the field of materials, can solve the problems of poor material structure stability, unsatisfactory thermoelectric performance, uncontrollable component content, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 10 g of aniline monomer, dissolve in 200 ml of 2M HCl solution, and stir with a magnetic force at 200 r / min. Weigh ammonium persulfate (APS) according to the molar ratio of ammonium persulfate and aniline monomer 1:1, dissolve it in 200ml 0.1M HCl solution, and add APS dropwise into the aniline monomer solution. Ice-water bath reaction 8 hours;

[0033] (2) washing the reaction product of step (1) with ethanol and deionized water to neutrality, and drying at 100° C. to obtain intrinsic polyaniline (EB);

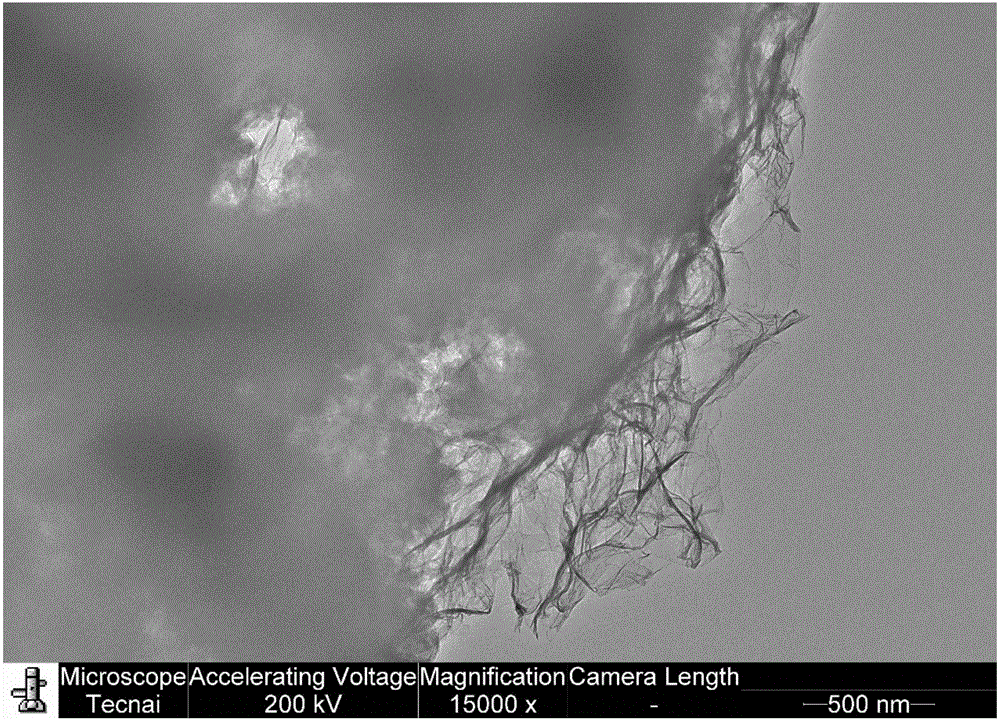

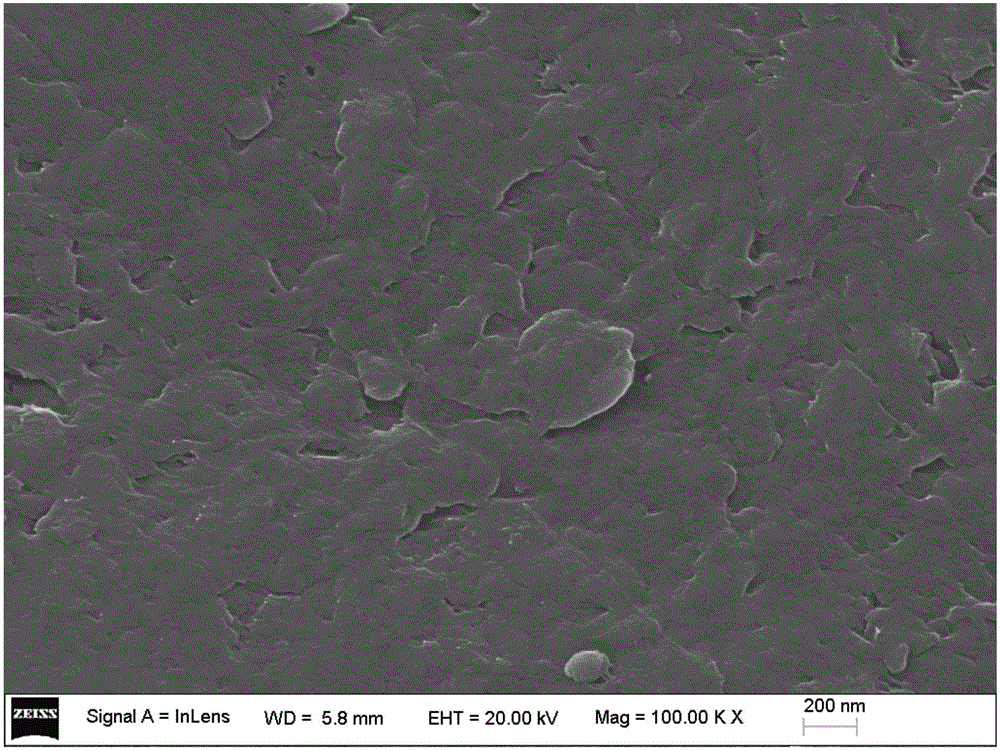

[0034] (3) Disperse 10mg of graphene oxide in 10ml of deionized water, ultrasonically disperse for 1h, and prepare a graphene dispersion of 1mg / ml; weigh 90mg of the synthesized polyaniline powder and disperse it in the above-mentioned graphene dispersion, 400r / ml Min magnetic stirring for 1 h, ultrasound for 30 min to obtain a uniform graphene-polyaniline dispersion solution. Graphene accounts for 10% by mass of the total mixture.

[0035] (4) Add 100 μL ...

Embodiment 2

[0040]The polyaniline preparation part of this example is the same as steps (1) and (2) in Example 1 except for the following parameters. In step (1), the stirring speed is 600r / min, and the reaction time is 3h. The molar concentration of HCl solution is 1M / L; the molar ratio of oxidant ammonium persulfate to aniline monomer is 3:1.

[0041] (3) Disperse 20mg of graphene oxide in 10ml of deionized water, ultrasonically disperse for 1h, and prepare a 2mg / ml graphene dispersion; weigh 80mg of the synthesized polyaniline powder and disperse it in the above-mentioned graphene dispersion, 400r / ml Min magnetic stirring for 1 h, ultrasound for 30 min to obtain a uniform graphene-polyaniline dispersion solution. Graphene accounts for 20% by mass of the total mixture.

[0042] (4) Add 400 μL of ammonia solution to the solution obtained in step (1), continue stirring for 1 h, and sonicate for 30 min. After sealing the solution, put it into an oven, heat treatment at 80° C., and react ...

Embodiment 3

[0047] The polyaniline preparation part of this example is the same as steps (1) and (2) in Example 1 except for the following parameters. In step (1), the stirring speed is 800r / min, and the reaction time is 5h. The molar concentration of HCl solution is 2M / L; the molar ratio of oxidant ammonium persulfate to aniline monomer is 5:1.

[0048] (3) Disperse 20mg of graphene oxide in 10ml of deionized water, ultrasonically disperse for 1h, and prepare a 2mg / ml graphene dispersion; weigh 30mg of the synthesized polyaniline powder and disperse it in the above-mentioned graphene dispersion, 400r / ml Min magnetic stirring for 1 h, ultrasound for 30 min to obtain a uniform graphene-polyaniline dispersion solution. Graphene accounts for 40% of the total mixture mass.

[0049] (4) Add 400 μL of ammonia solution to the solution obtained in step (1), continue stirring for 1 h, and sonicate for 30 min. After sealing the solution, put it into an oven, heat treatment at 110° C., and react f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com