Bent flexible transparent strain sensor production method

A strain sensor, bending technology, applied in nanotechnology for sensing, electric/magnetic solid deformation measurement, nanotechnology, etc., to achieve the effect of low cost, high sensitivity and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

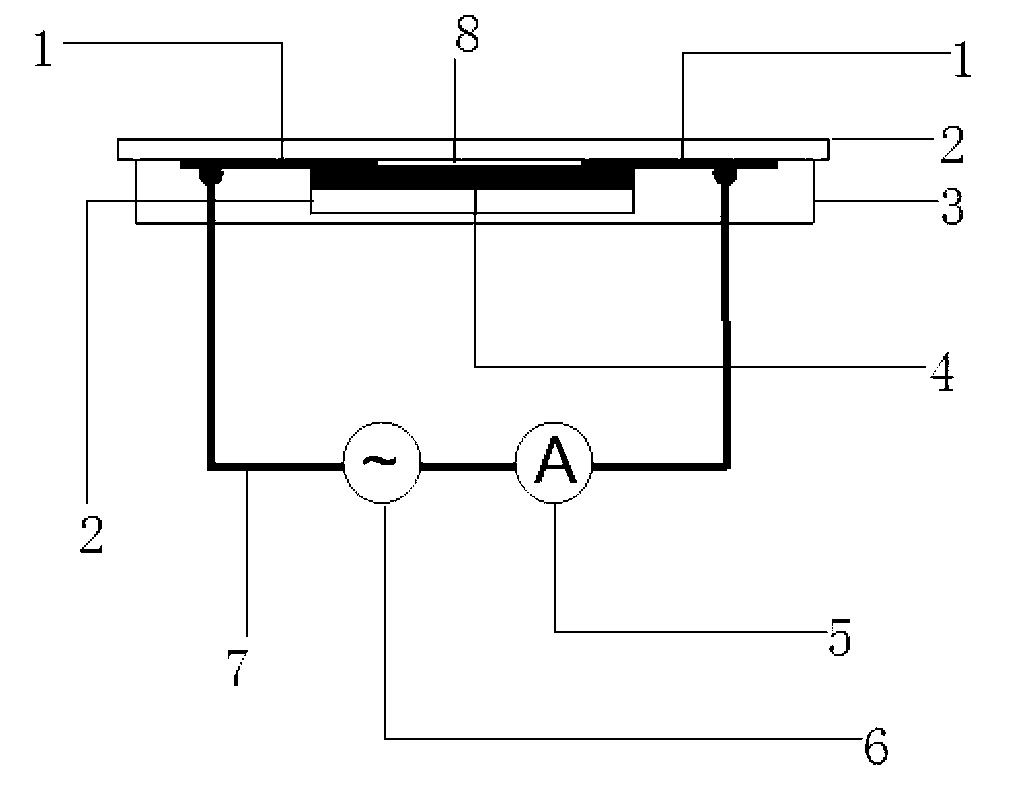

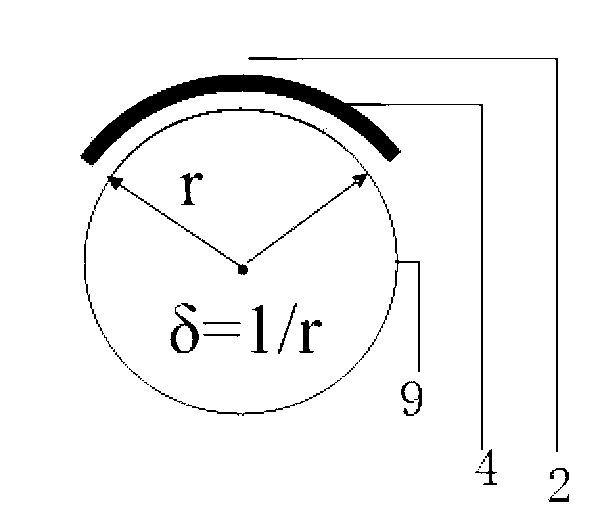

Method used

Image

Examples

Embodiment

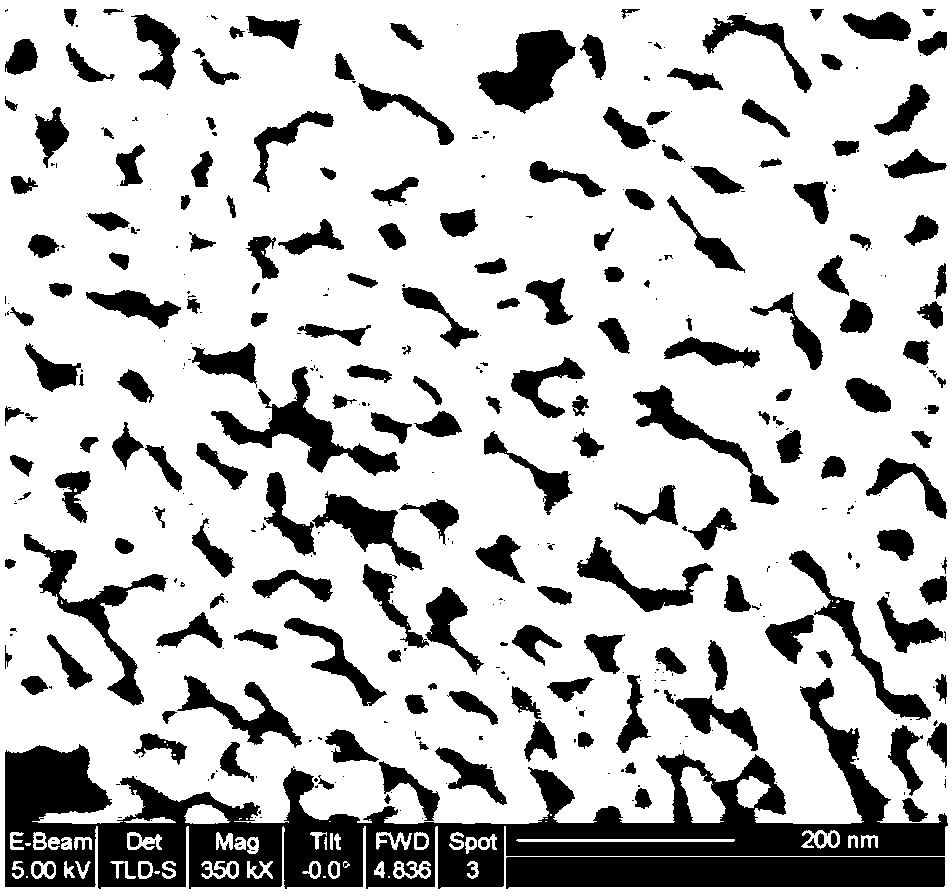

[0021] In this example, the polyaniline nano film is used as the functional layer to prepare a curved flexible transparent strain sensor, and the specific process steps are as follows:

[0022] (1) Select a polyester film as a flexible substrate, and ultrasonically clean the polyester film with acetone, absolute ethanol, and deionized water respectively to obtain a clean polyester film substrate;

[0023] (2) Dissolving camphorsulfonic acid in deionized water to form a camphorsulfonic acid aqueous solution with a camphorsulfonic acid concentration of 0.025 mol / liter; then adding aniline monomer into the camphorsulfonic acid aqueous solution, the concentration of aniline monomer is 0.02 mol / liter ; finally adding hydrogen peroxide with a concentration of 0.02 mol / liter to prepare a polyaniline reaction solution;

[0024] (3) Immerse the clean polyester film substrate vertically in the polyaniline reaction solution for 2 hours, then take it out after immersing it in m-cresol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com