Radial extruding forming device of cut-fiber reinforcement rubber composite material

A technology of short fiber reinforcement and composite materials, which is applied to other household appliances, tires, household appliances, etc., can solve the problems of low production efficiency, cumbersome operation, and only applicable, etc., and achieve product quality improvement, wide application range, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

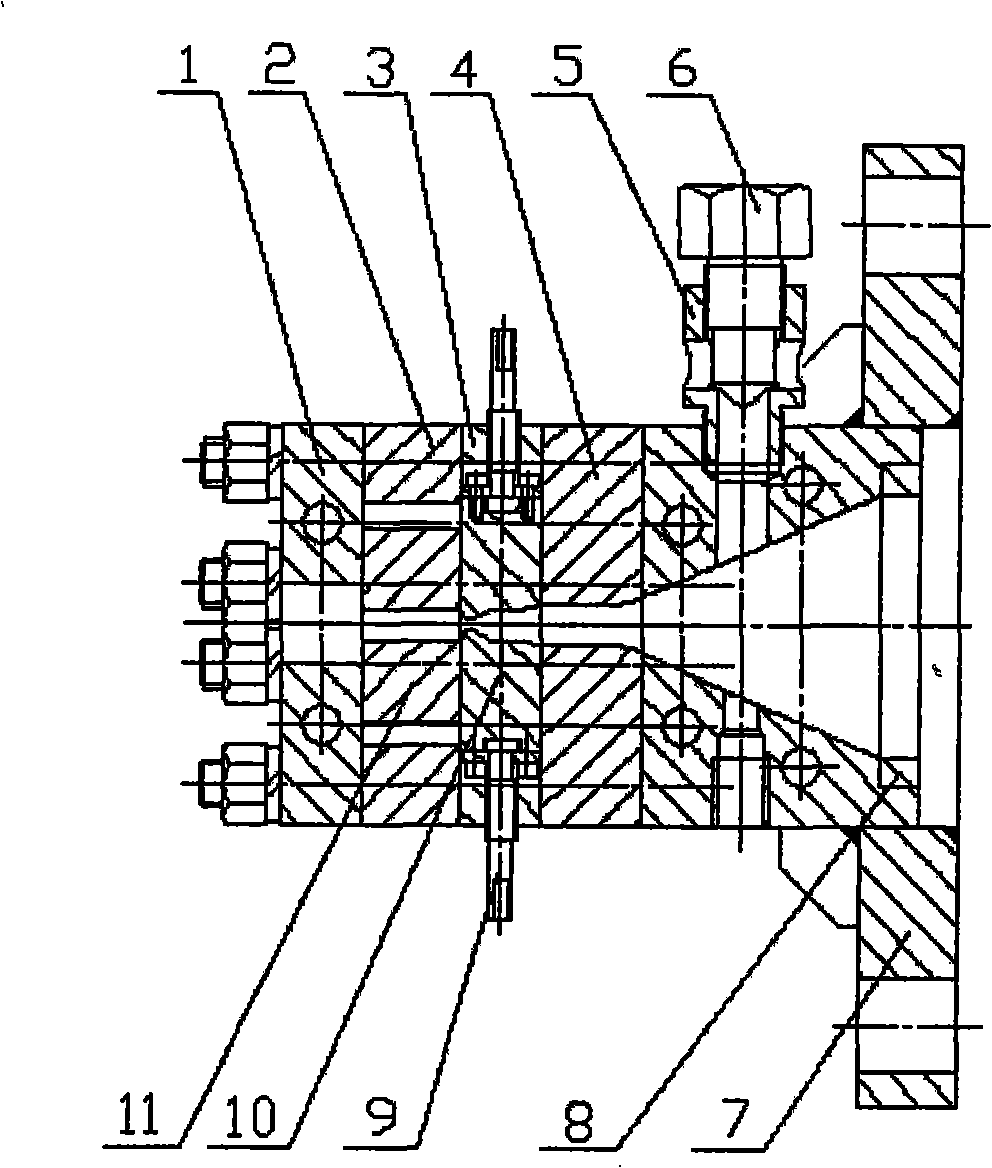

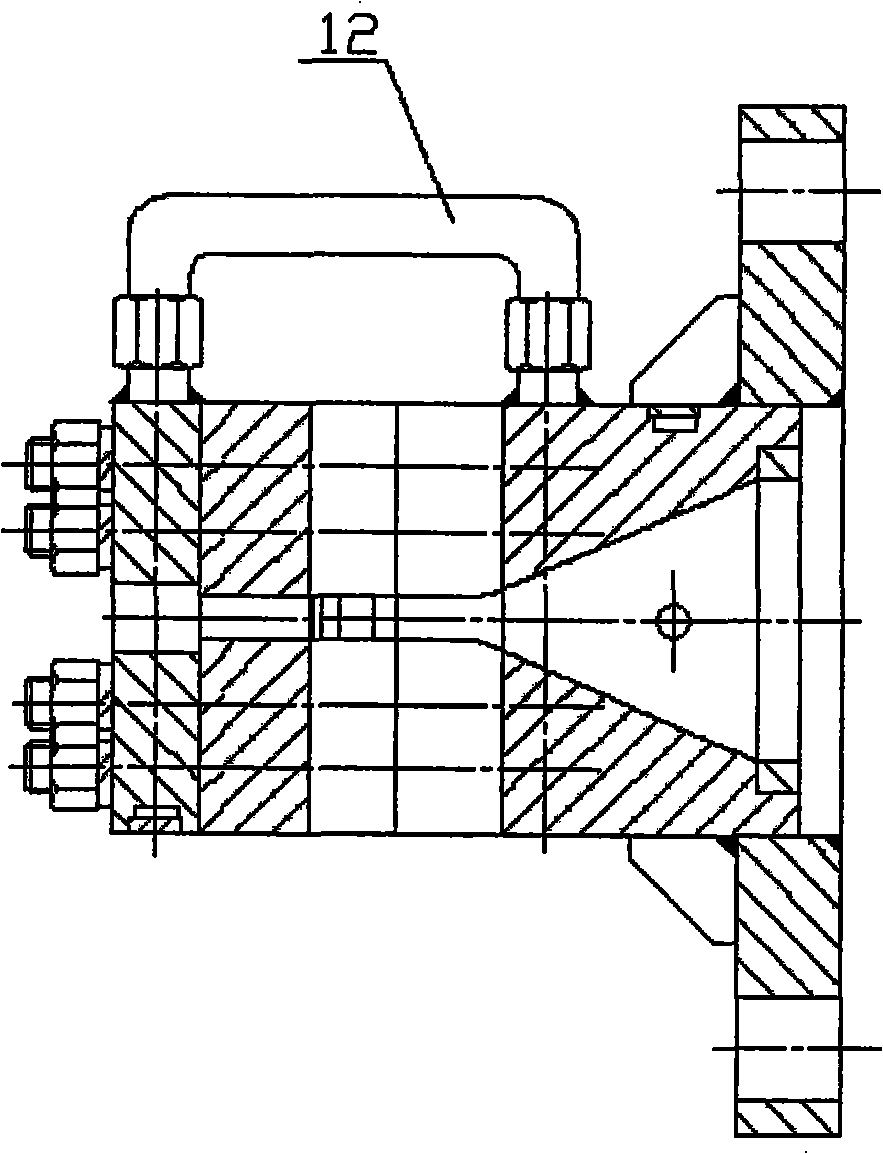

[0011] The main structure of this embodiment includes the head pressure plate 1, the shaping plate 2, the dam support plate 3, the flow channel plate 4, the overflow valve 5, the overflow adjustment bolt 6, the flange 7, the rubber filter plate 8, the dam adjustment Bolt 9, dam adjustment block 10, shaping adjustment block 11 and high temperature and high pressure water pipe 12, the main body of the machine head device is composed of flange 7, flow channel plate 4, dam support plate 3, shaping plate 2 and machine head pressure plate 1 , the inlet end of the machine head is designed as a tapered structure, the middle part is a rectangular cross-section structure, and the outlet end forms a dam-like structure by reducing the thickness of the flow channel; the flange 7 is connected with the flow channel plate 4, and the flow channel plate 4 is supported by the dam The plates 3 are connected, the dam support plate 3 is connected with the shaped plate 2, and the shaped plate 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com