Patents

Literature

69results about How to "Low technical level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

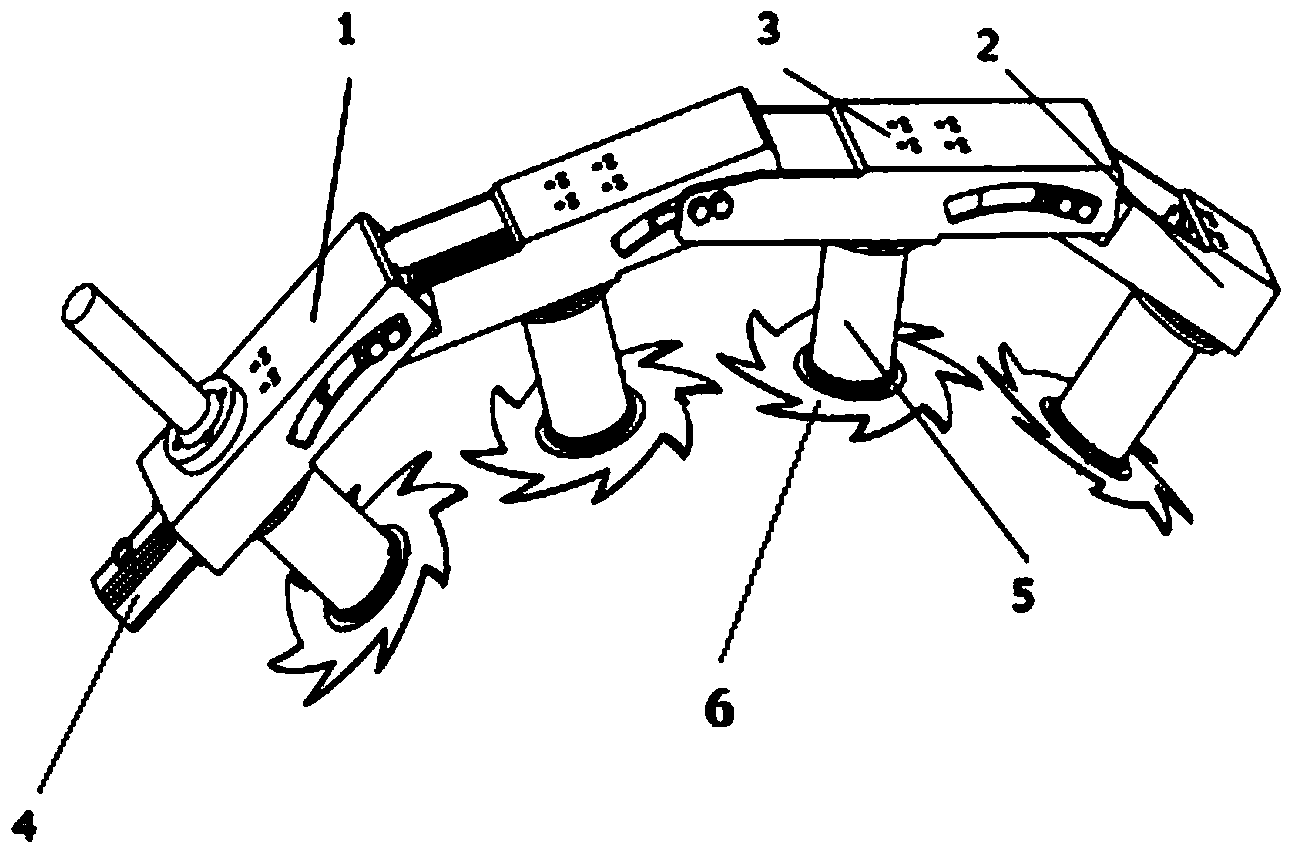

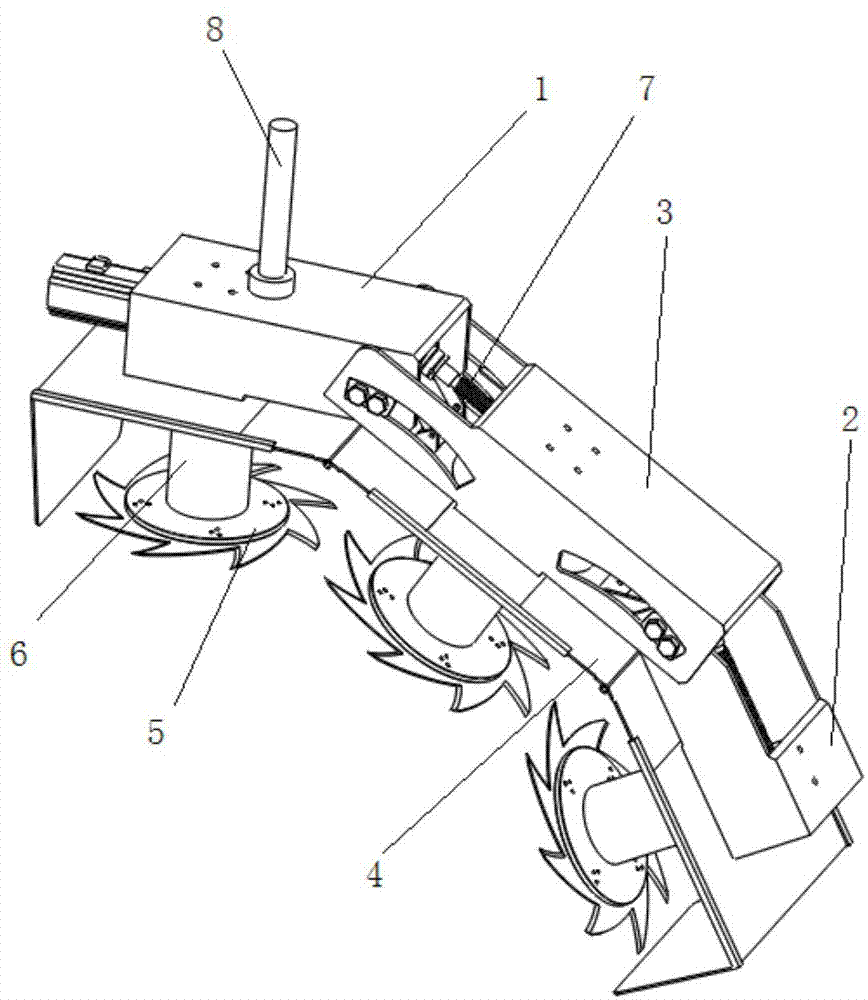

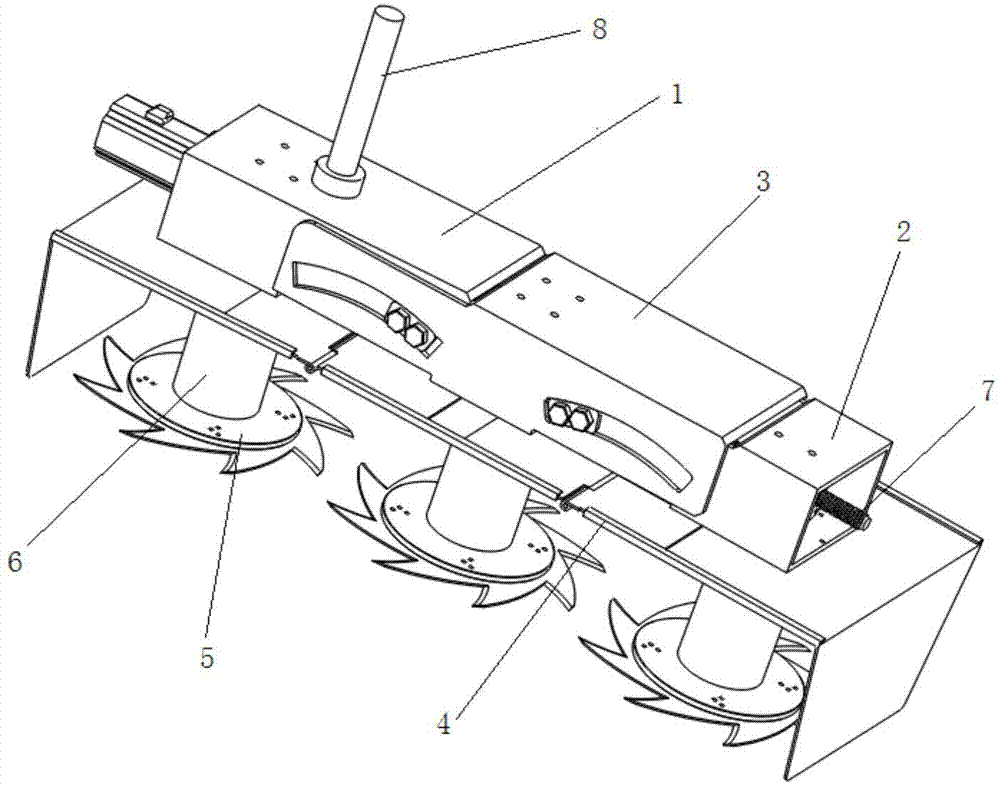

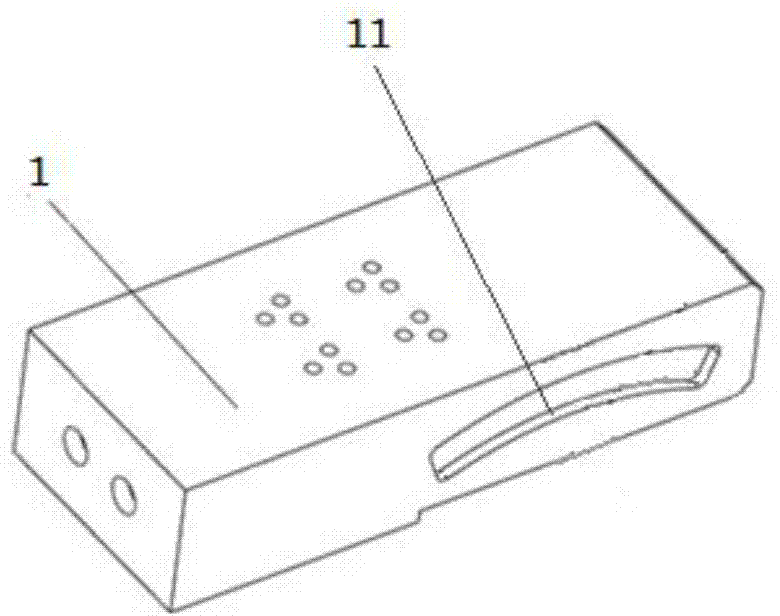

Novel hedge modeling cutter

The invention discloses a novel hedge modeling cutter which comprises a first rack, a second rack, pruning cutters, first driving devices and a driving mechanism. The first rack and the second rack are fixedly provided with the first driving devices with the pruning cutters, one end of the first rack is provided with an arc-shaped sliding track, one end of the second rack is provided with an arc-shaped sliding block corresponding to the sliding track, the second rack is connected with the sliding track of the first rack in a matched mode through the sliding block, an included angle between the second rack and the first rack is adjusted by changing the position of the sliding block on the sliding track, and the driving mechanism can change the position of the sliding block on the sliding track. According to the novel hedge modeling cutter, the combination shape of the cutter can be automatically changed to adapt to modeling of the horizontal faces, the vertical faces and the geometric curved surfaces of hedges. The novel hedge modeling cutter is simple in structure, convenient to use and efficient.

Owner:南宁市合辰科技有限公司

Field welding and stabilizing heat treatment method of thick-wall pipeline

ActiveCN101564802ALow technical levelWith construction conditionsArc welding apparatusFurnace typesButt weldingSulfur

The invention provides a field butt welding and stabilizing heat treatment method of austenitic stainless steel thick-wall pipeline containing stabilizing elements, which comprises the steps of welding and stabilizing heat treatment. In the welding materials, the weight ratio of chromium to nickel is larger than 1.6, the weight ratio of manganese to silicon is larger than 3, the total weight content of sulfur and phosphorus is less than 0.01 percent, the weight ratio of stabilizing elements to carbon is 8-11, and the weight content of ferrite is 5 to 11 percent. The method can well realize the construction of welding and heat treatment of the austenitic stainless steel thick-wall pipeline containing stabilizing elements.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

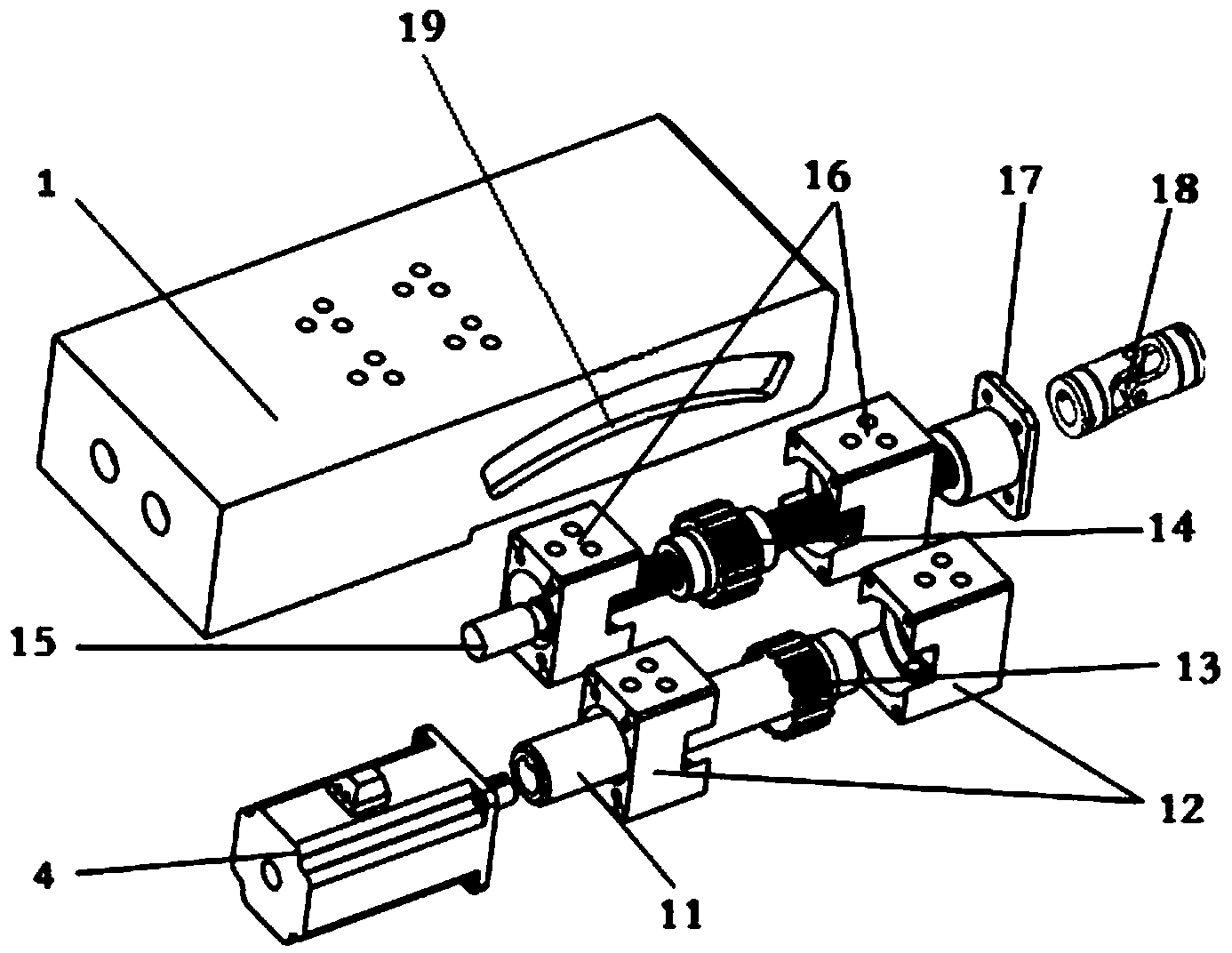

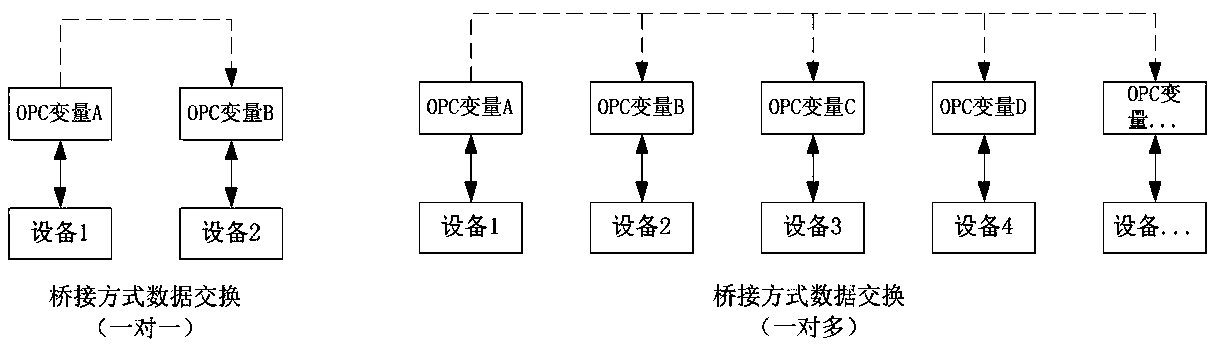

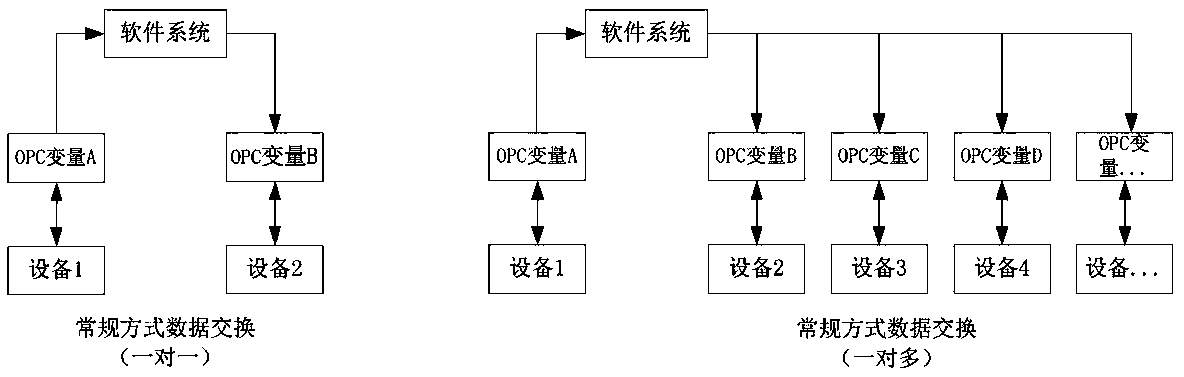

Industrial control system bottom layer integrated architecture of digital foundry factory

ActiveCN107807618AEasy to takeLow technical levelTransmissionTotal factory controlFoundryData source

The invention discloses an industrial control system bottom layer integrated architecture of a digital foundry factory. The industrial control system bottom layer integrated architecture includes an OPC server, a data acquisition unit, a data exchange unit and a data scheduling unit; the OPC server is sued for performing overall control on an entire system; the data acquisition unit is used for acquiring the bottom-layer data of the foundry factory; the data exchange unit is used for realize interlocking and data communication among equipment units in the foundry factory; the data scheduling unit performs comprehensive analysis operation on a plurality of data in different systems and gives a final result, and is used for guiding the implementation of field equipment or personnel; and thedata acquisition unit, the data exchange unit, and the data dispatch unit are all connected with the OPC server. With the industrial control system bottom layer integrated architecture of the invention adopted, bottom-layer engineers can be emancipated themselves from tedious repeated communication and coordination work. The industrial control system bottom layer integrated architecture is applicable to the application conditions of various data sources.

Owner:NINGXIA KOCEL MOLD

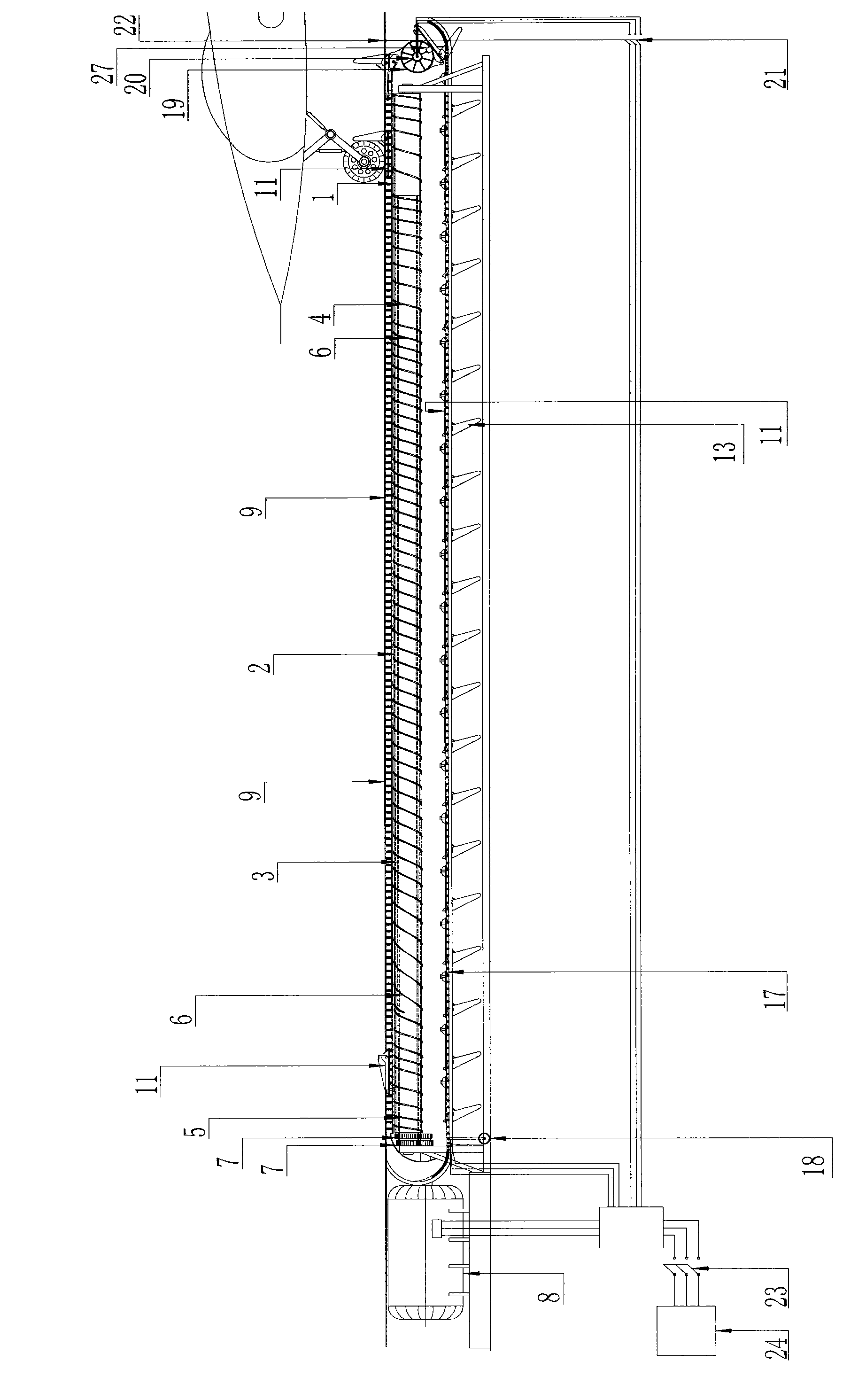

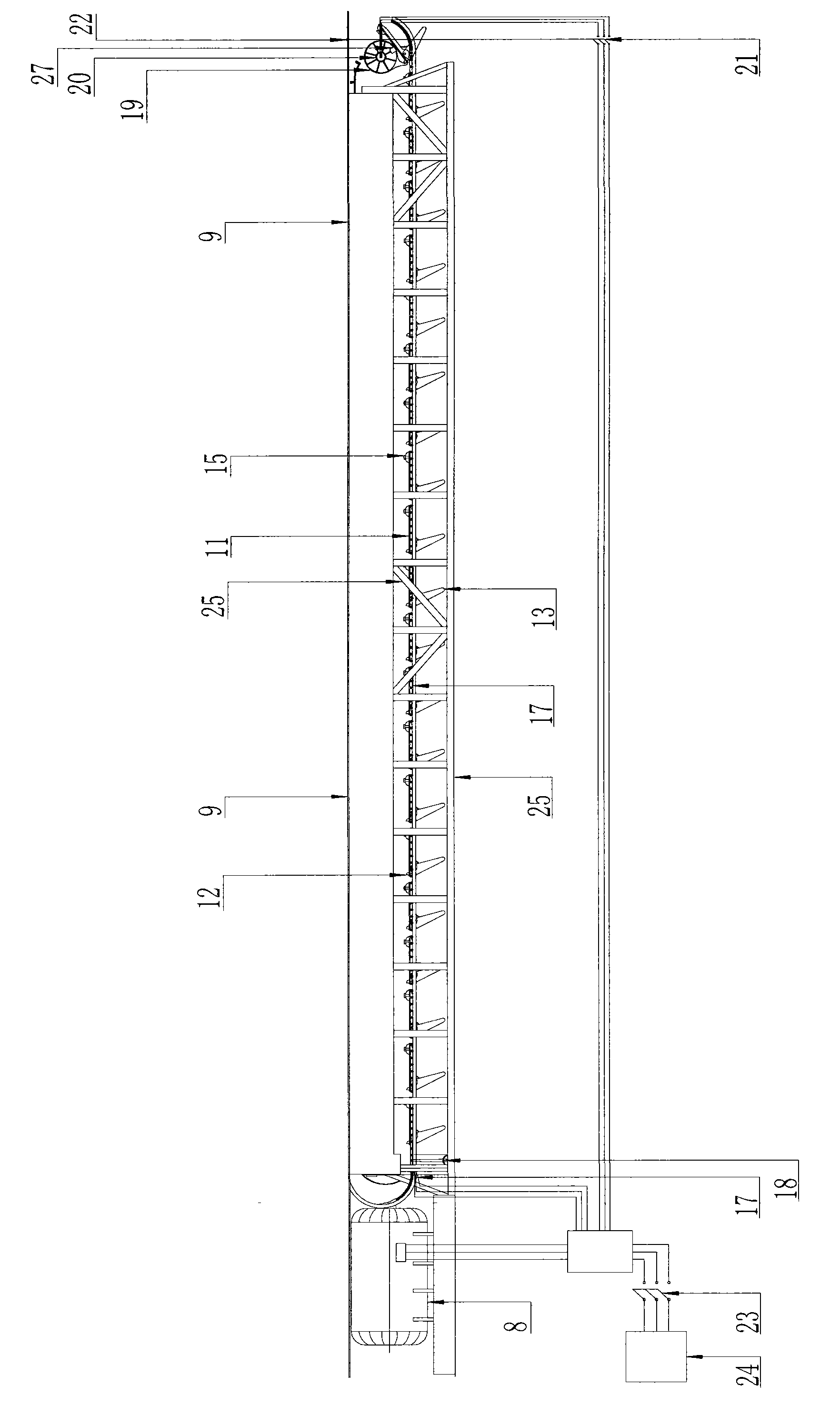

Repeating aircraft catapult

InactiveCN101954974AWeight increaseIncrease maximum speedLaunching/towing gearShortest distancePower equipment

The invention relates to a repeating aircraft catapult which is a device for supplying power for aircraft in short distance on land, warships and aircraft carrier decks. The repeating aircraft catapult comprises a first-level acceleration main shaft, a second-level acceleration main shaft, a transmission shaft, an acceleration spiral orbit, a deceleration spiral orbit, a counterweight spiral orbit, a change gear, a rotary power source, an acceleration orbit, a main shaft positioning wheel, a transmission trolley, a trolley starting hook, a trolley arm, an arm closing spring, a trolley acceleration wheel, a trolley positioning wheel, a trolley pass-back orbit, a pass-back motor, a trolley starting wheel, a starting wheel motor, a starting wheel switch, a pressure switch, an equipment main switch, a main power supply, an equipment steel skeleton, a bearing or bearing bush, an electromagnet and the like. The repeating aircraft catapult can accelerate 40-ton aircraft to 80 m / s in 105-m distance within 5 s. The invention has the characteristics of less auxiliary equipment, simple maintenance and mature power equipment technology, can adopt gas engines, steam turbines and the like, and can continuously accelerate aircraft take-off.

Owner:栾远刚

Foamed glass ceramic material for wall and its production process

InactiveCN1389417AImprove performanceImprove mechanical propertiesConstruction materialCeramic materials productionMetallurgyGlass-ceramic

The present invention discloses a nucleated foamed glass wall body material, which is characterized byt aht its composition contains glass powder whose grain size d(0.9) is less than 130 meshes, flyash whose grain size d(0.9) is les than 120 meshes and non-metallic mineral powder whose grain size d(0.9) is less than 230 meshes. Its preparation method includes: grinding glass powder, flyash and non-metallic mineral powder, adding water and mixing them, under the condition of containing water content pressing and forming, drying and kilning, cutting blank and forming to obtain the invented product. It is suitable for industrial production.

Owner:NANJING UNIV +1

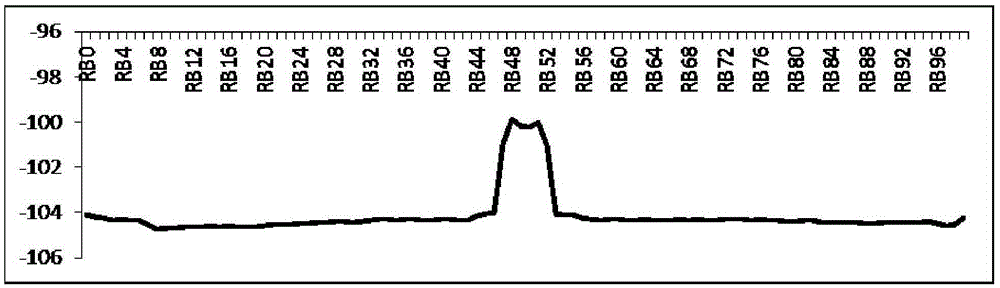

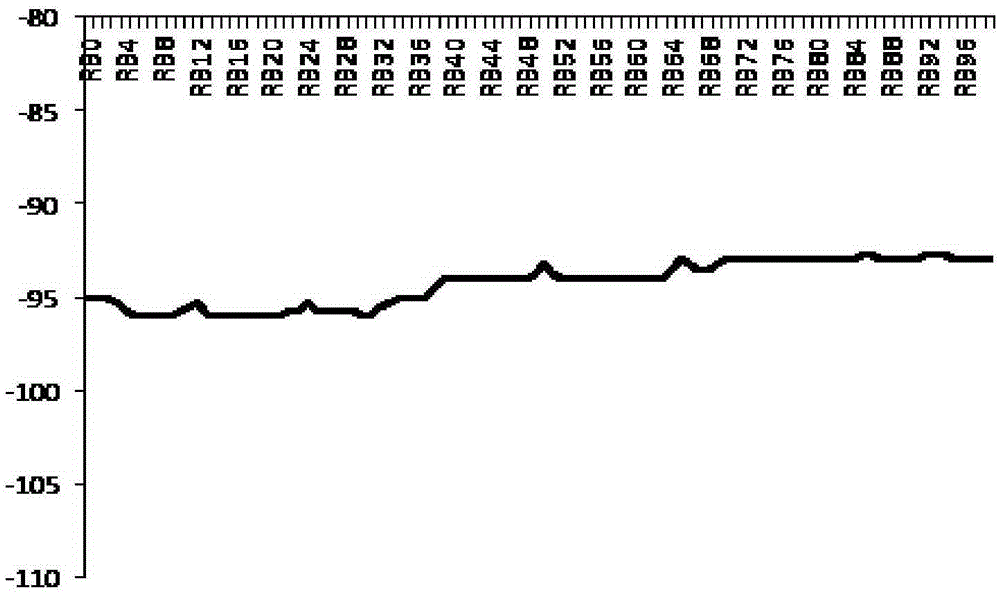

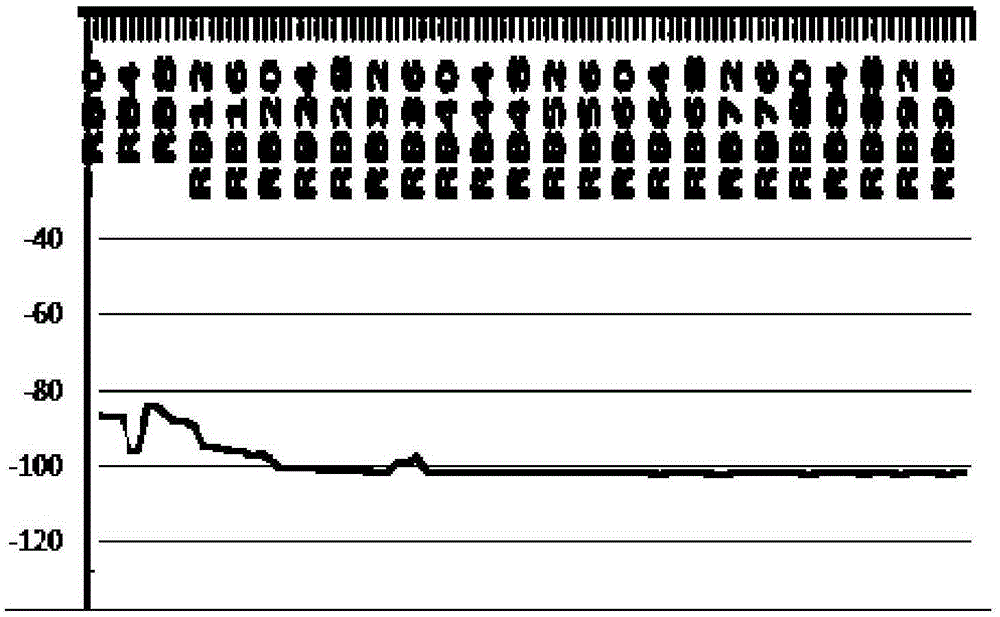

Method and device for determining interference type

ActiveCN106788587AHigh speedLow technical levelTransmission monitoringWireless communicationReliability engineeringElectrical and Electronics engineering

The invention provides a method and a device for determining the interference type. The method comprises the steps of acquiring target PRB data of a high-interference cell within a preset time period; matching the target PRB data with multiple groups of PRB feature information one by one, wherein each group of PRB feature information corresponds to one interference type; and determining the interference type corresponding to the group of PRB feature information which is successfully matched with the target PRB data to be the interference type of the high-interference cell. According to the invention, the uplink interference type of a TD-LTE base station can be analyzed and determined automatically, so that the type of interference suffered by the TD-LTE base station can be confirmed accurately and efficiently.

Owner:BOCO INTER TELECOM

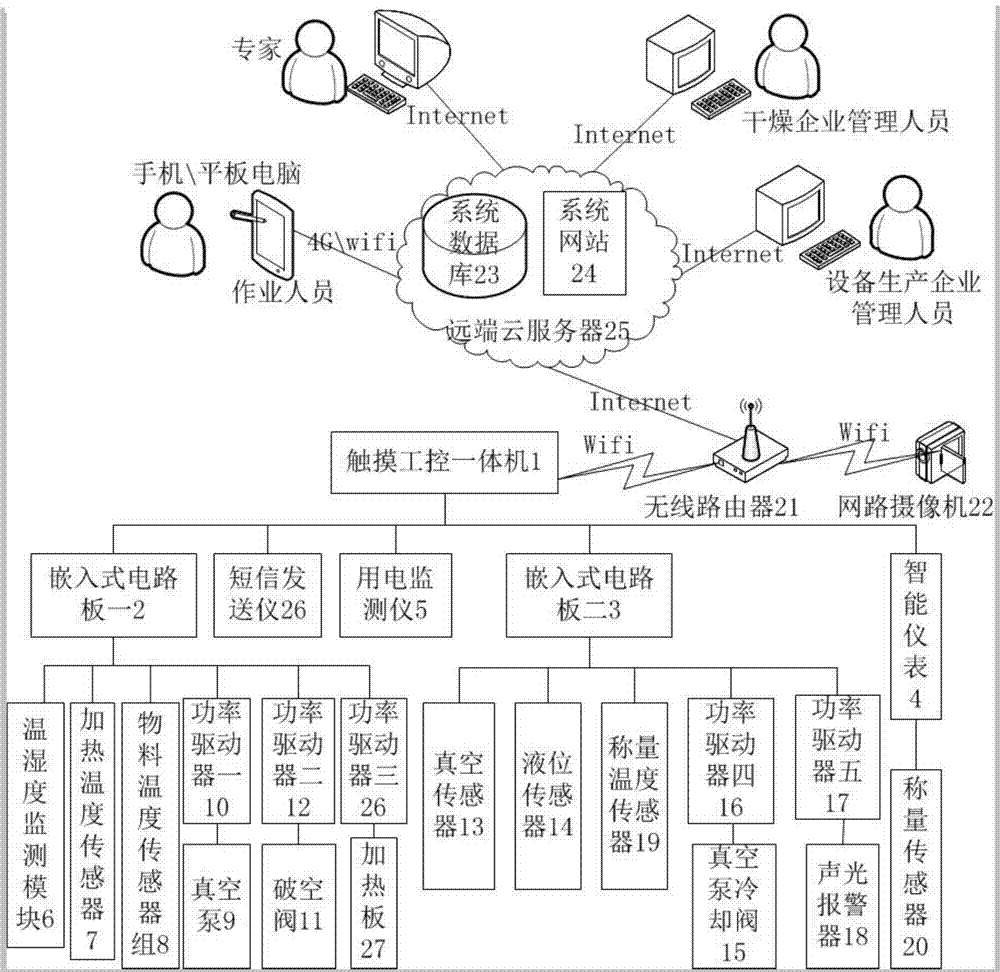

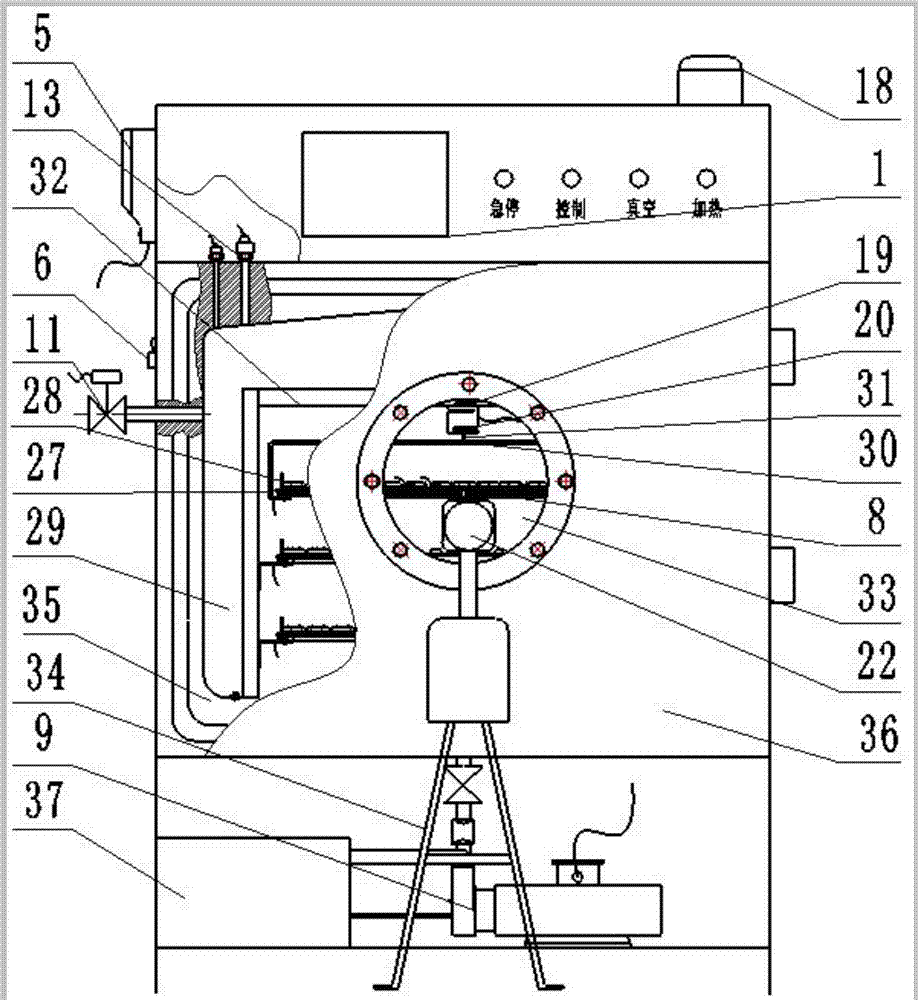

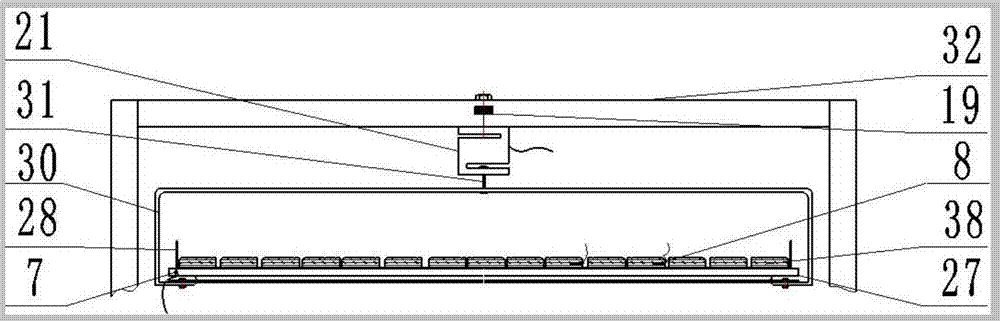

Vacuum pulse drying networking remote multi-parameter monitoring and information service system

InactiveCN106857797ALow technical levelSolve field expert technical support manpowerData processing applicationsFruits/vegetable preservation by dehydrationAutomatic controlEngineering

The invention belongs to the technical field of farm product processing, and particularly relates to a vacuum pulse drying multi-parameter monitoring and information service system. The vacuum pulse drying multi-parameter monitoring and information service system comprises an equipment site monitoring layer, a cloud end system website, a database layer and a network user layer. The vacuum pulse drying multi-parameter monitoring and information service system simultaneously has the functions in various aspects such as multi-aspect key parameter (material image, material weight and water content, and inside temperature) online detection and equipment automatic control, remote equipment monitoring, expert consultation service, overhaul guidance and fruit and vegetable processing professional knowledge study; the problems of low technical level of operation personnel, high field expert technical support labor and time cost, lack of comprehensive drying process key parameter online detection function and system integration and the like in the vacuum pulse drying technology popularization and application are solved; the advantages of modular design, function expansion, use and maintenance convenience, low cost and the like are realized.

Owner:SHAANXI UNIV OF SCI & TECH

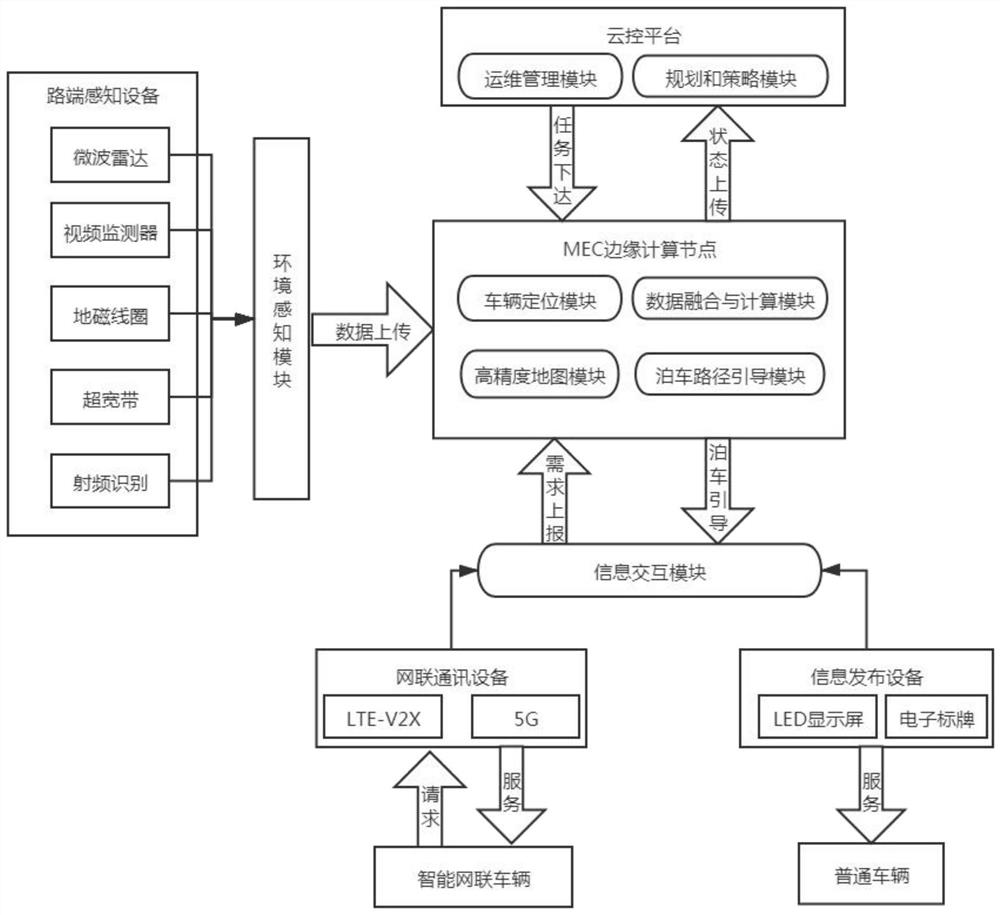

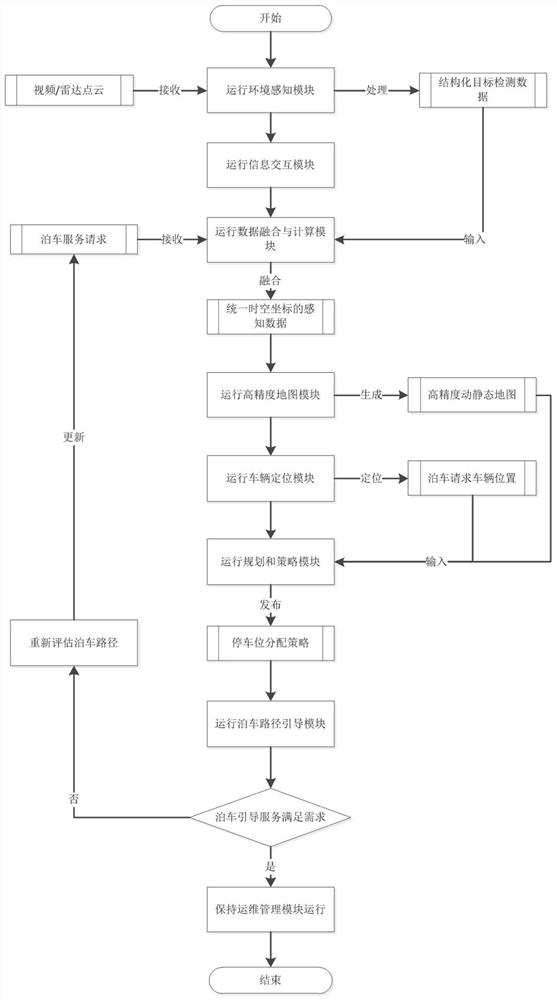

Autonomous parking system and method based on multi-access edge computing

ActiveCN112562409AAvoid congestionAvoid delayParticular environment based servicesAnti-collision systemsEdge computingNetwork communication

The invention relates to an autonomous parking system and method based on multi-access edge computing, and the system takes a sunken business processing mode and an edge computing node as a core, andcomprises an environment sensing module, a vehicle positioning module, a high-precision map module, a planning and strategy module, a data fusion and calculation module, an information interaction module, a parking path guiding module and an operation and maintenance management module. The system is carried on a road end sensing device, a network communication device, an information publishing device and a cloud control platform. According to the invention, large-scale vehicle parking business requirements can be processed in a low-delay and non-blocking mode, the vehicle parking requirementsare dynamically updated, the high-precision sensing capacity of the surrounding environment is achieved, safe, accurate and efficient parking guide path service can be provided, vehicles do not need to have the automatic driving capacity, and convenience, high efficiency, safety and rapidness are achieved.

Owner:上海淞泓智能汽车科技有限公司

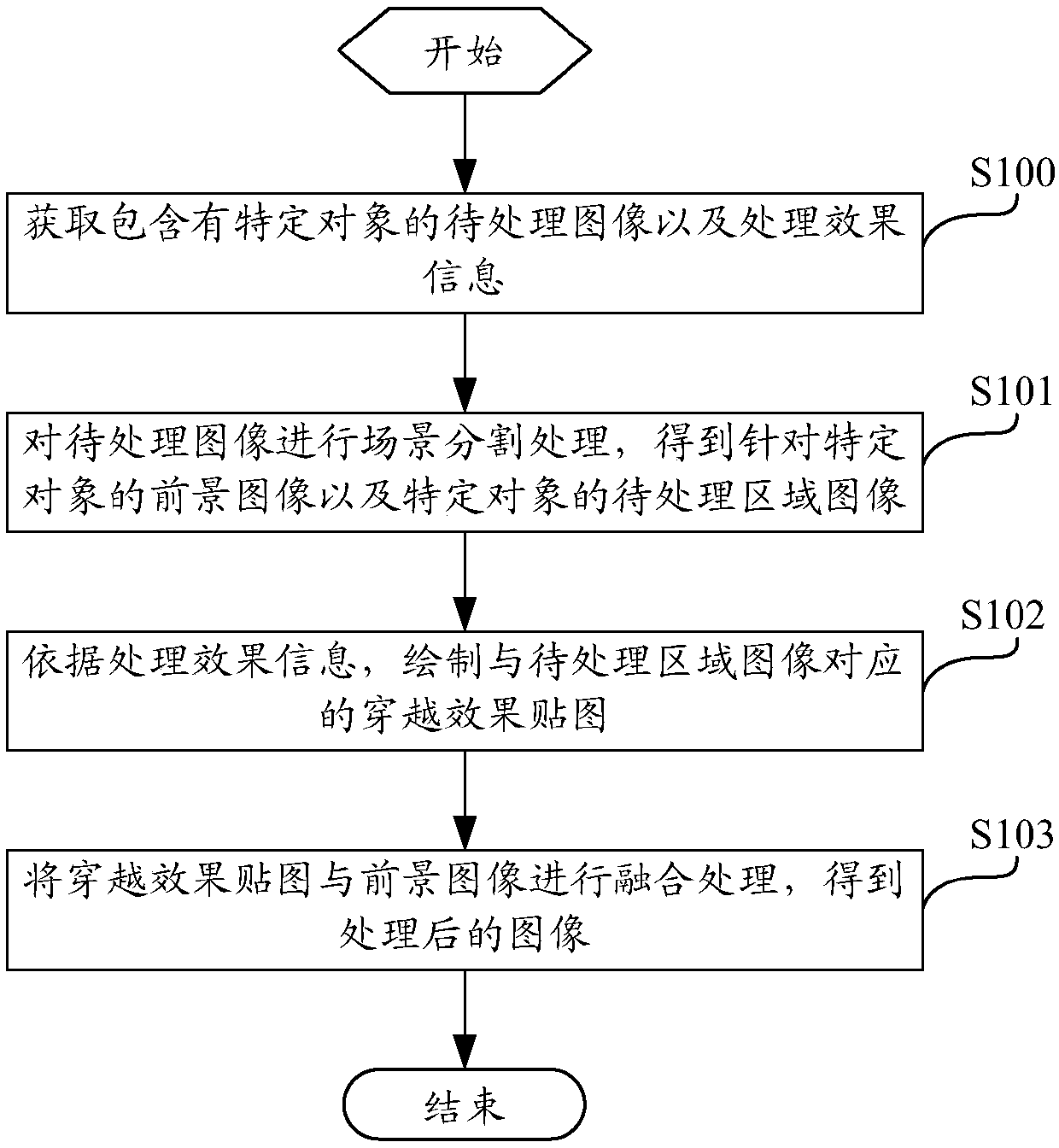

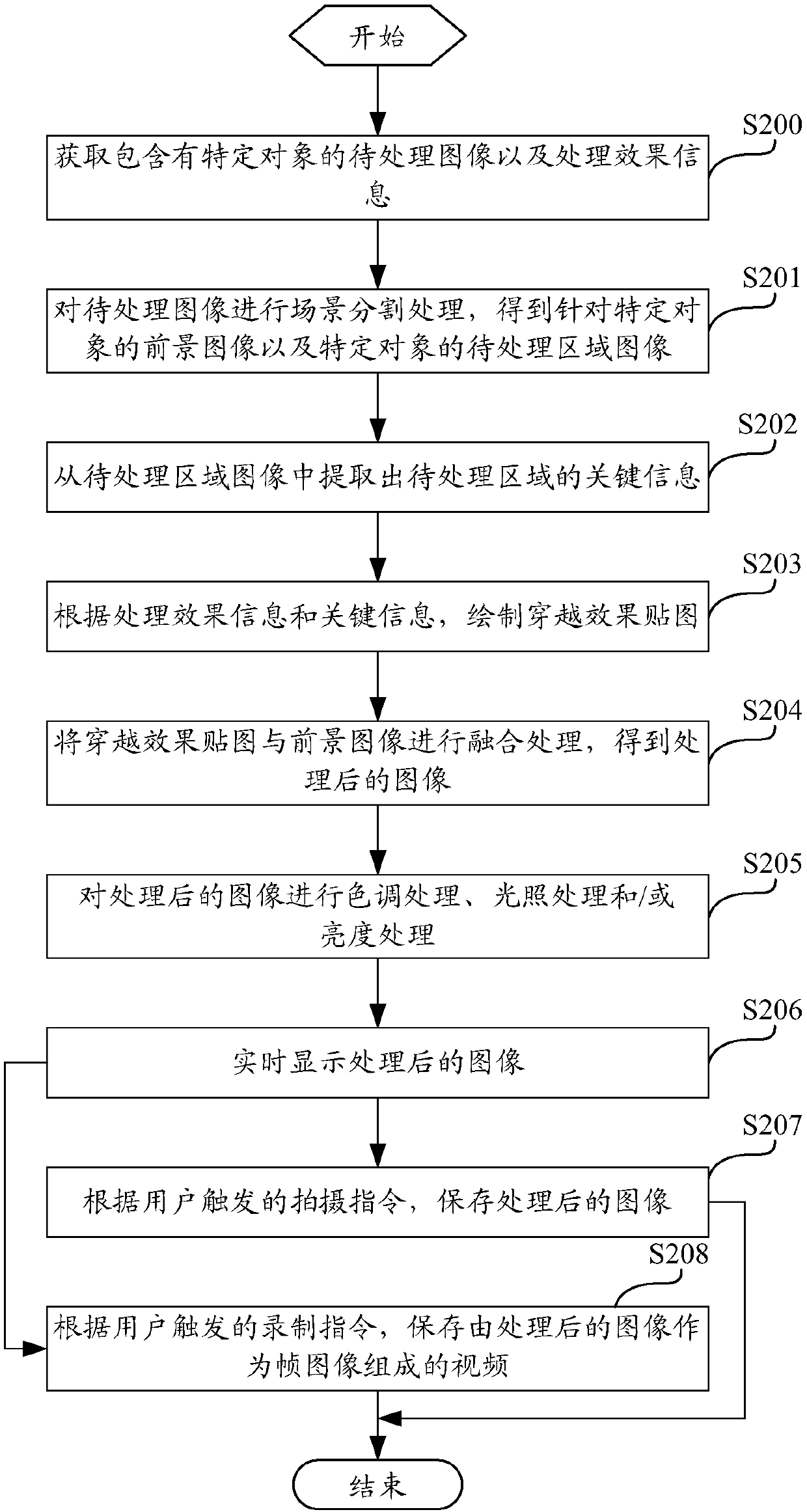

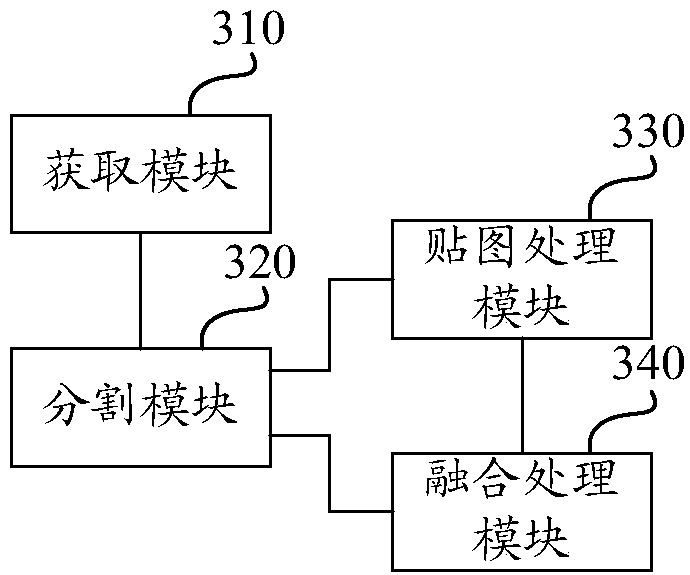

Image through processing method and device, computation equipment and computer storage medium

ActiveCN107808372AImprove processing efficiencyImprove the display effectImage enhancementImage analysisScene segmentationProcess region

The invention discloses an image through processing method and device, computation equipment and a computer storage medium. The method comprises the following steps that: obtaining to-be-processed image which contains a specific object, and processing effect information; carrying out scene segmentation processing on the to-be-processed image to obtain a foreground image which aims at the specificobject, and the image of the to-be-processed region of the specific object; on the basis of the processing effect information, drawing a through effect map corresponding to the image of the to-be-processed region; carrying out fusion processing on the through effect map and the foreground image to obtain a processed image, wherein the through effect map comprises one or multiple of the following maps: a clothes effect map, a decoration effect map, a texture effect map and a face make-up effect map. By use of the method, a deep learning method is adopted, and scene segmentation processing is finished at high efficiency and high accuracy. A through effect can be accurately and quickly added to the to-be-processed area of the image to obtain an image with a through effect.

Owner:BEIJING QIHOO TECH CO LTD

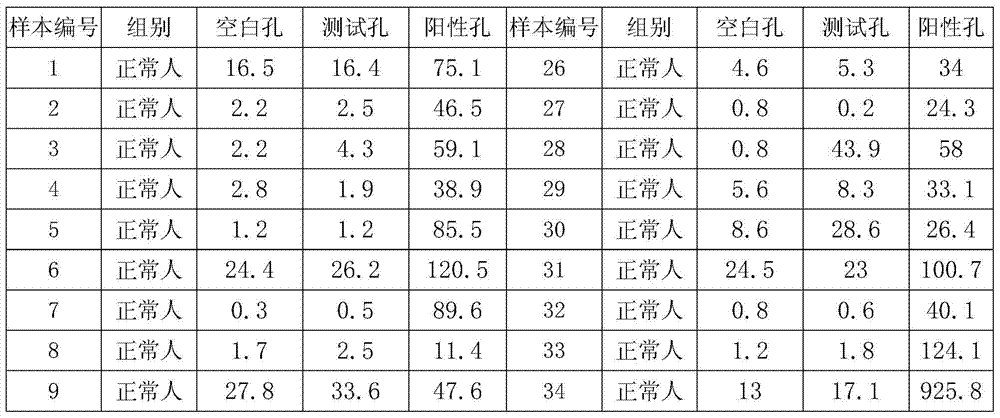

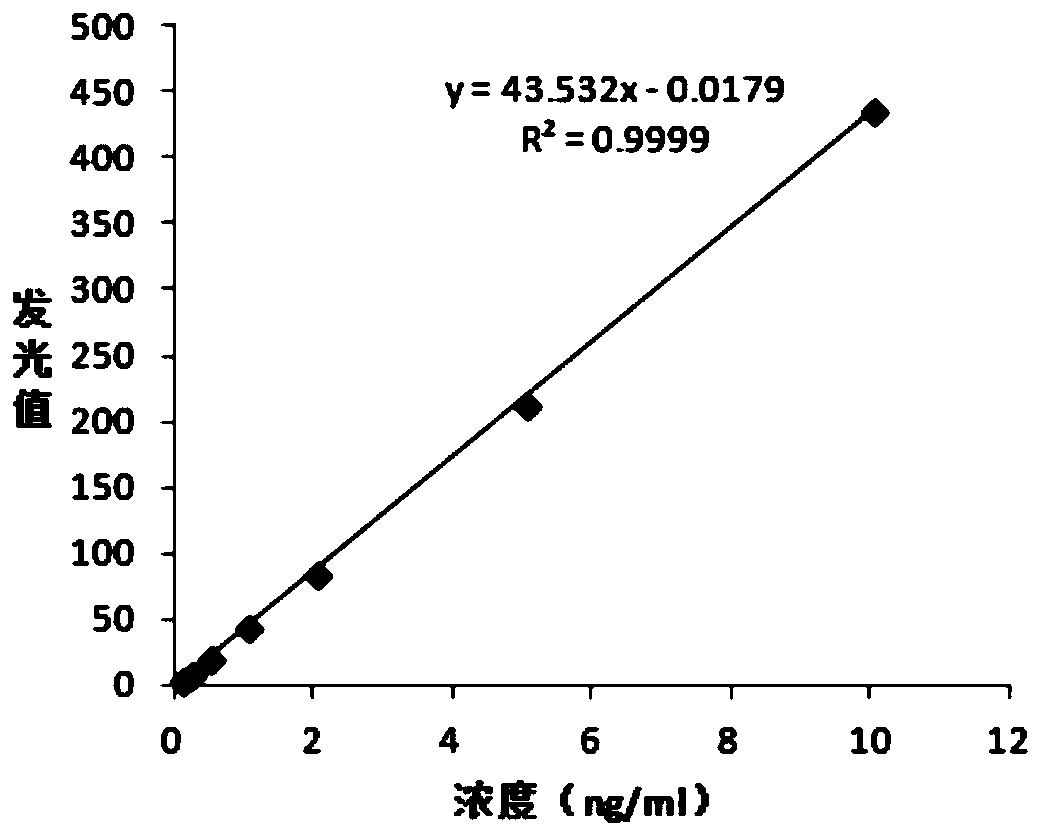

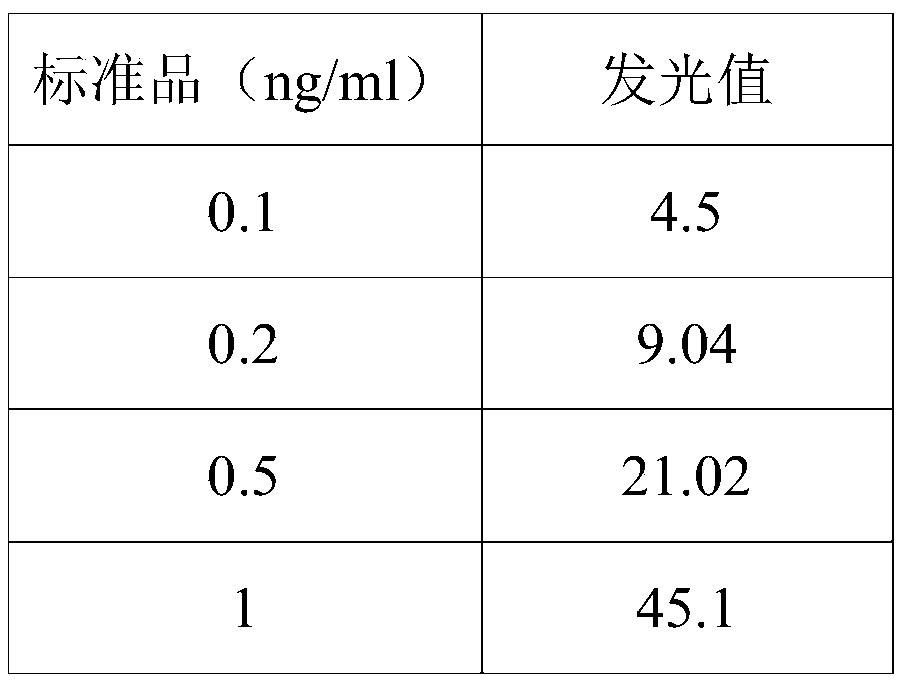

Magnetic-bead chemiluminescence kit for detection of tuberculosis infection and application thereof

InactiveCN106996928AEfficient detectionLow technical levelChemiluminescene/bioluminescenceBiotin-streptavidin complexMagnetic bead

The invention discloses a magnetic-bead chemiluminescence kit for detection of tuberculosis infection. The kit comprises a streptavidin magnetic-bead suspension, a gamma interferon calibrator, phytolectin (PHA), mycobacterium tuberculosis specific antigenic polypeptide, a serum-free culture solution (AIM-V), biotin-labeled anti-human gamma interferon monoclonal antibody, alkaline phosphatase labeled anti-human gamma interferon monoclonal antibody, a luminescent substrate solution (APS 5), a calibrator diluent, an antibody diluent and a cleaning solution. According to the kit, an opaque white enzyme label plate is used for the detection. In comparison with traditional enzyme-linked immunoassay, the kit of the invention has higher sensitivity, is simple and fast to operate, is low-cost, is easy to realize automatic operation, and has a good clinic application prospect.

Owner:SHANGHAI FOSUN LONG MARCH MEDICAL SCI CO LTD

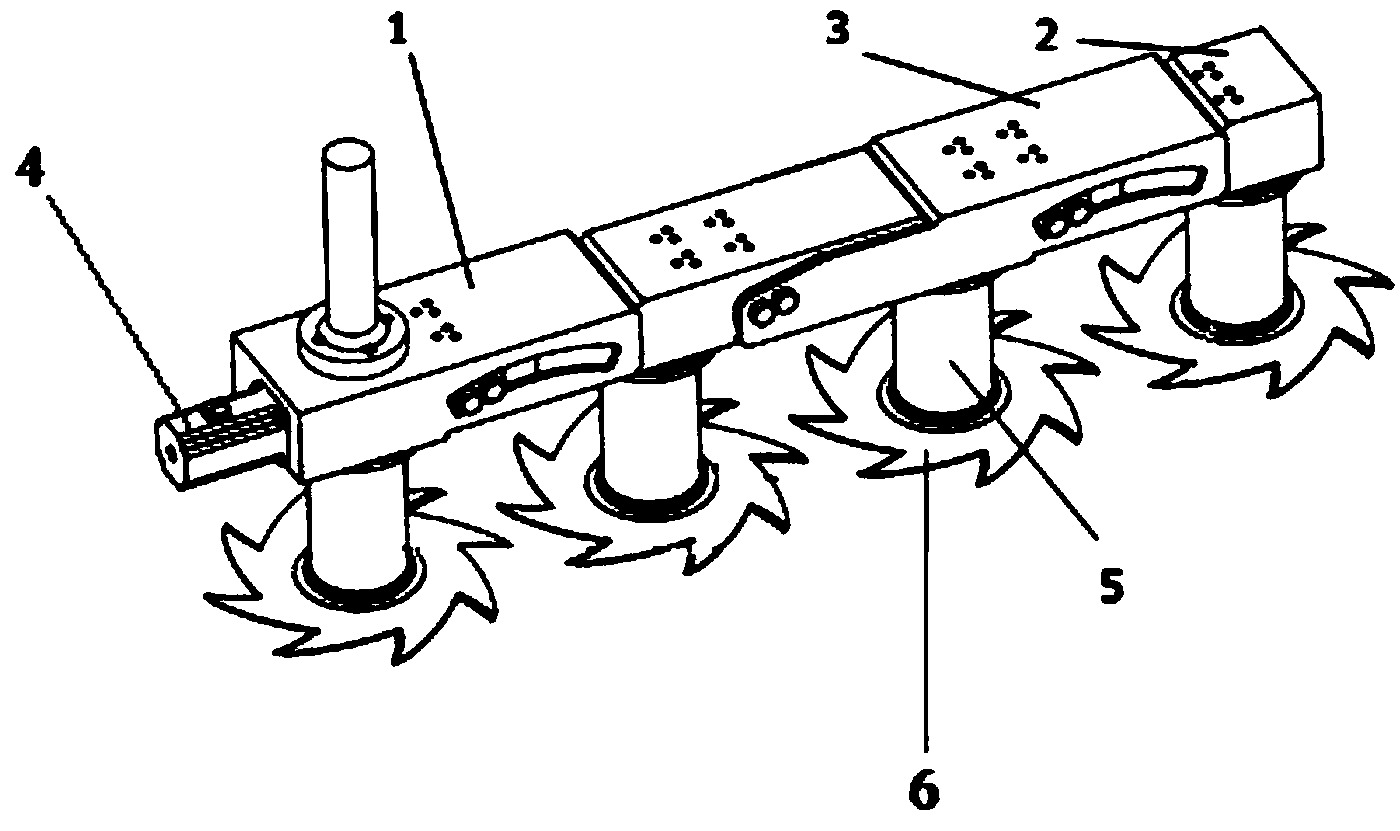

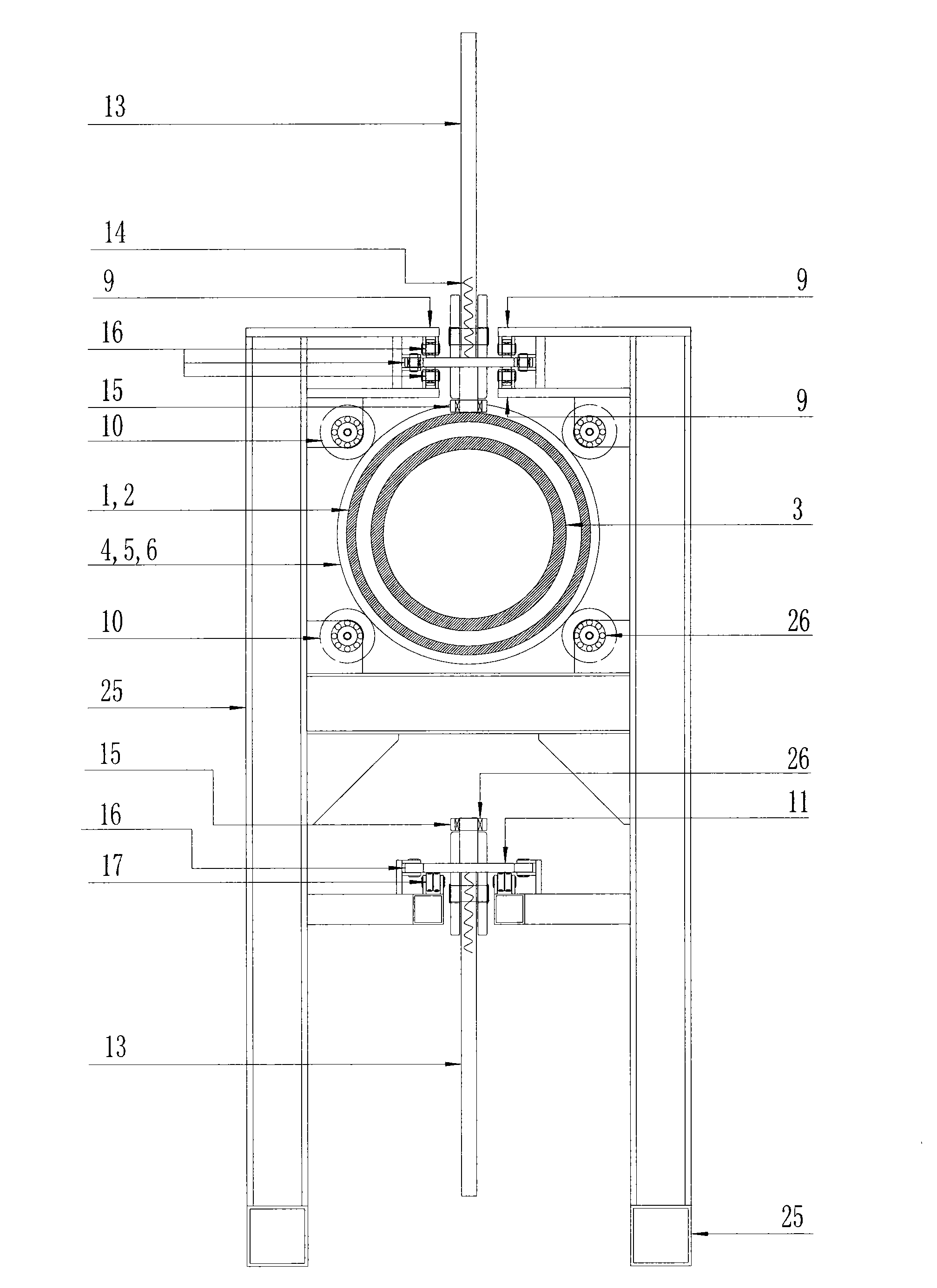

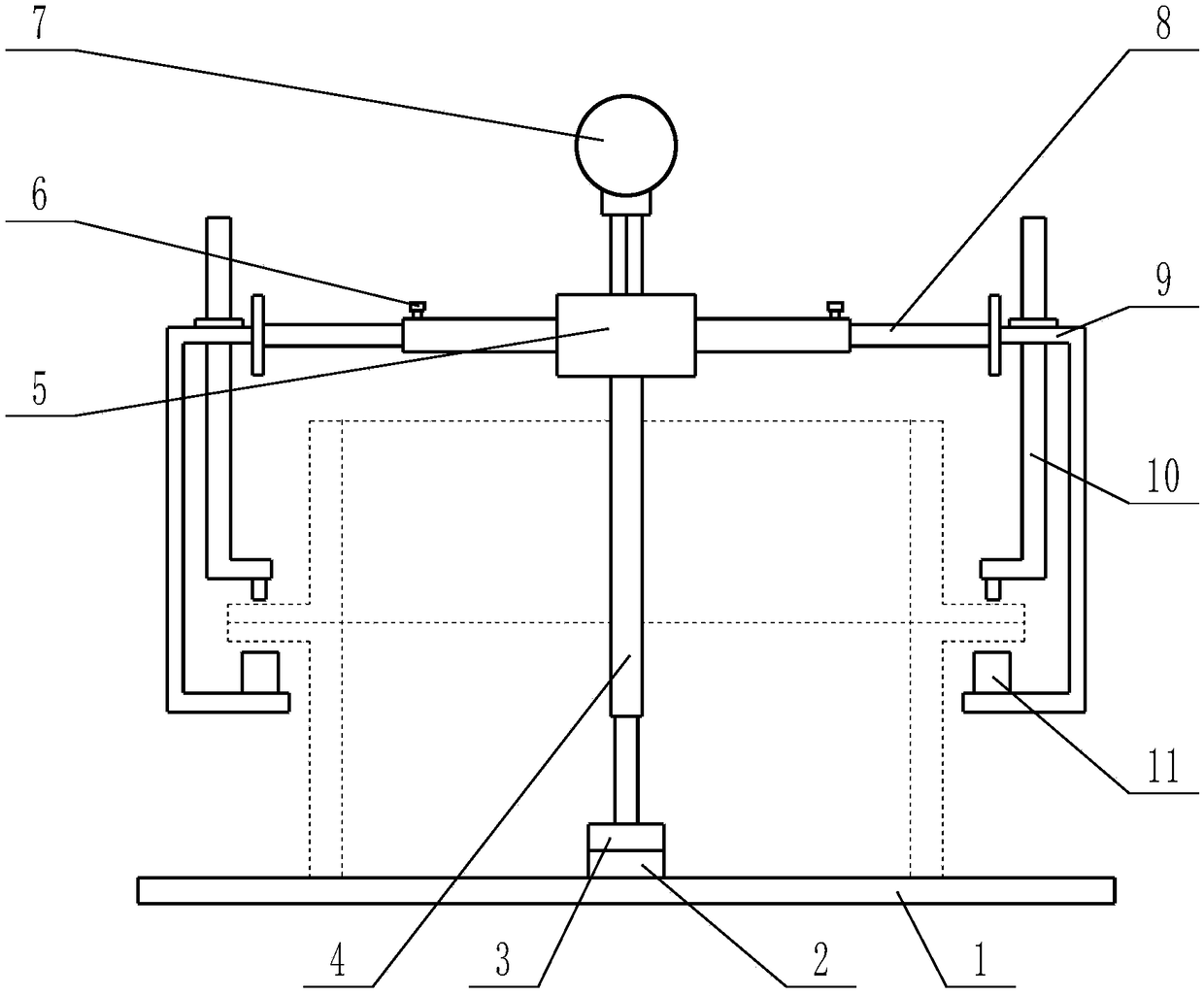

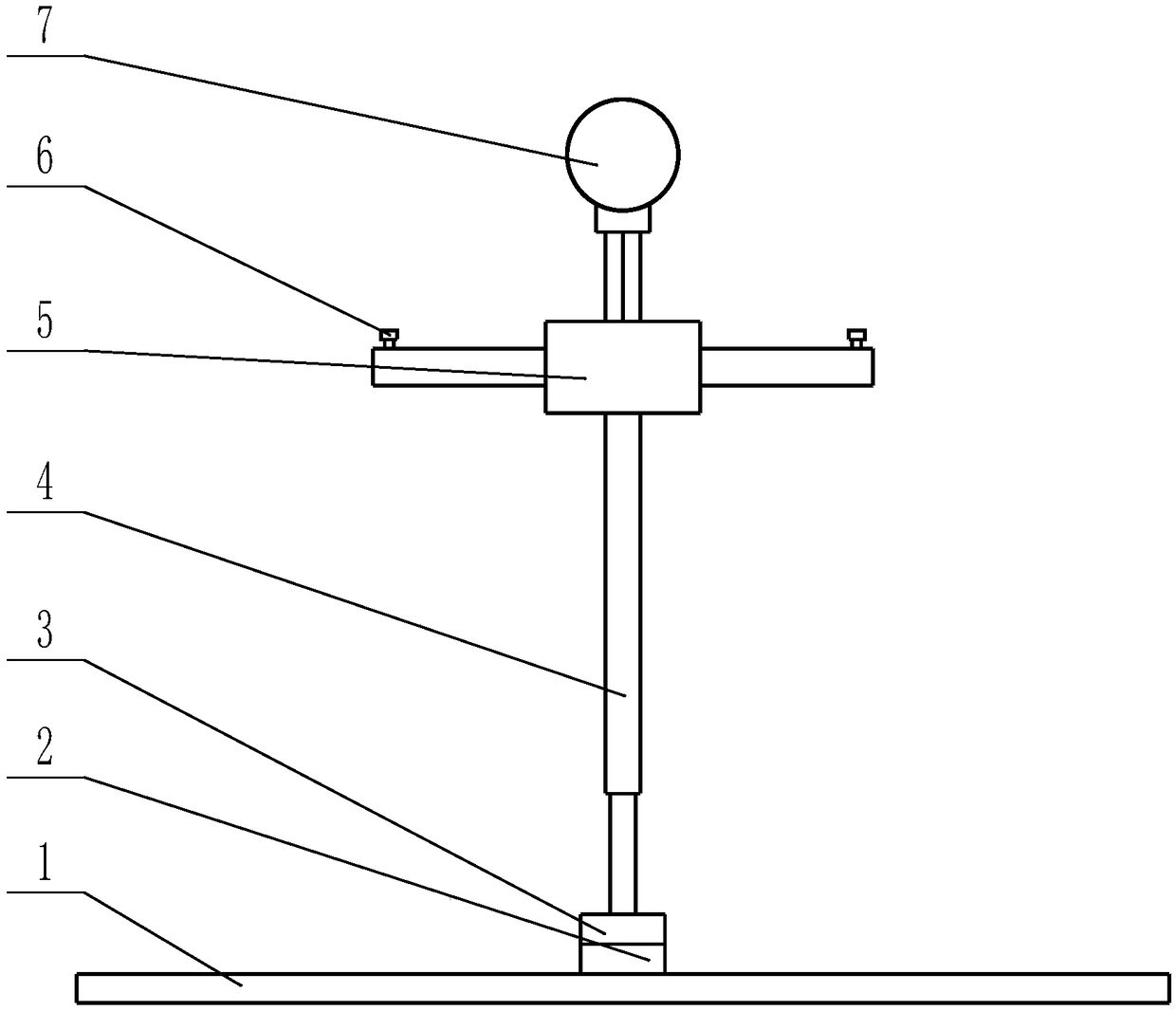

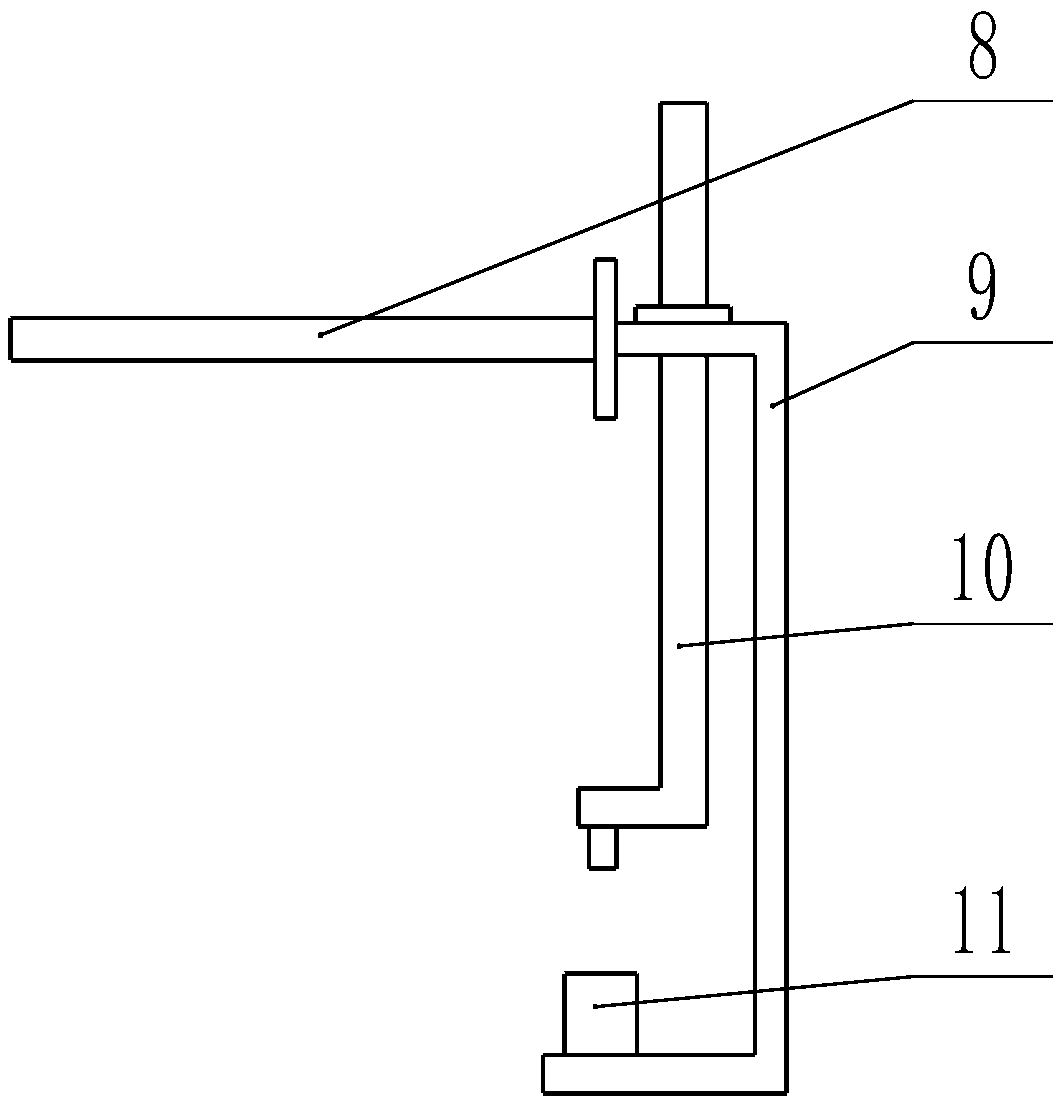

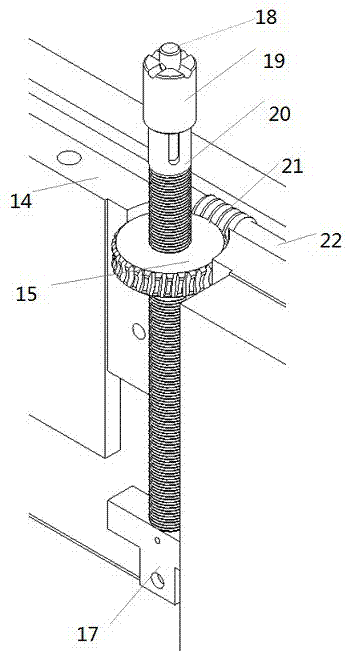

Multi-axis vertical screw-up device applied to aeroengine case and using method of multi-axis vertical screw-up device

InactiveCN109159078AReduce labor intensityLow technical levelMetal-working hand toolsEngineeringMulti axis

The invention discloses a multi-axis vertical screw-up device applied to an aeroengine case and a using method of the multi-axis vertical screw-up device. The multi-axis vertical screw-up device comprises a position regulating device and a screw-up device, wherein an indexing disc in the position regulating device is fixedly arranged on a workbench; the indexing disc is connected with a stand column through a stand column bracket; a mechanical arm sleeve is matched with a guide rail of the stand column; a balancer is fixedly arranged on the stand column, and a load end of the balancer is connected with the mechanical arm sleeve; a slide rod in the screw-up device is sleeved by a horizontal sleeve on the side surface of the mechanical arm sleeve, and is fixed by a fastening bolt arranged onthe horizontal sleeve; a clamp body is arranged on the slide rod; and a screw-up shaft and a displacement sensor are fixedly arranged on the clamp body. During working, the mechanical arm sleeve andthe slide rod separately regulate height and the horizontal distance of the screw-up shaft, so that the device is suitable for aeroengine cases of different types; and the displacement sensor measureslength deformation, in the screw-up process, of the bolt to obtain instant pre-tightening force of the bolt, so that torque of the screw-up shaft is regulated. The multi-axis vertical screw-up deviceimproves screw-up quality of the aeroengine case, and reduces technical requirements and labour intensity of a worker.

Owner:DALIAN UNIV OF TECH

Production process of 2cm thick dark ash modern antique brick specially designed for integral prefabricated wall body

The embodiment of the invention discloses a production process of a 2cm thick dark gray modern antique brick specially designed for an integral prefabricated wall body. The antique brick produced by the process is 2cm in thickness, has an original surface, integrity, wear resistance and antifouling property. Compared with a common 1cm ceramic product or a thin brick, the thick modern antique brickproduced by the process is 2cm in thickness, has an original surface and integrity, is more wear-resistant and antifouling, rich in color, soft and smooth in surface feel, more in line with the requirements of integral prefabrication, energy conservation and environmental protection of modern real estate walls, and enhances the market adaptability. The production process comprises the following steps: A, preparing formula materials including 10% of an antique material, 70% of dark ash, and 20% of medium-light ash; B, putting the formula materials into a ball mill, carrying out ball grinding to obtain a slurry, and carrying out sieving; C, carrying out atomization and drainage to prepare a powder, and feeding the powder into a powder bin for aging; D, feeding the prepared powder into a press mold for pressing; E, drying the molded material; F, applying bottom glaze to a glaze line and carrying out ink jet printing; and G, feeding the material into a kiln for firing to obtain a 2cm thick dark ash modern antique brick.

Owner:广东博华陶瓷有限公司

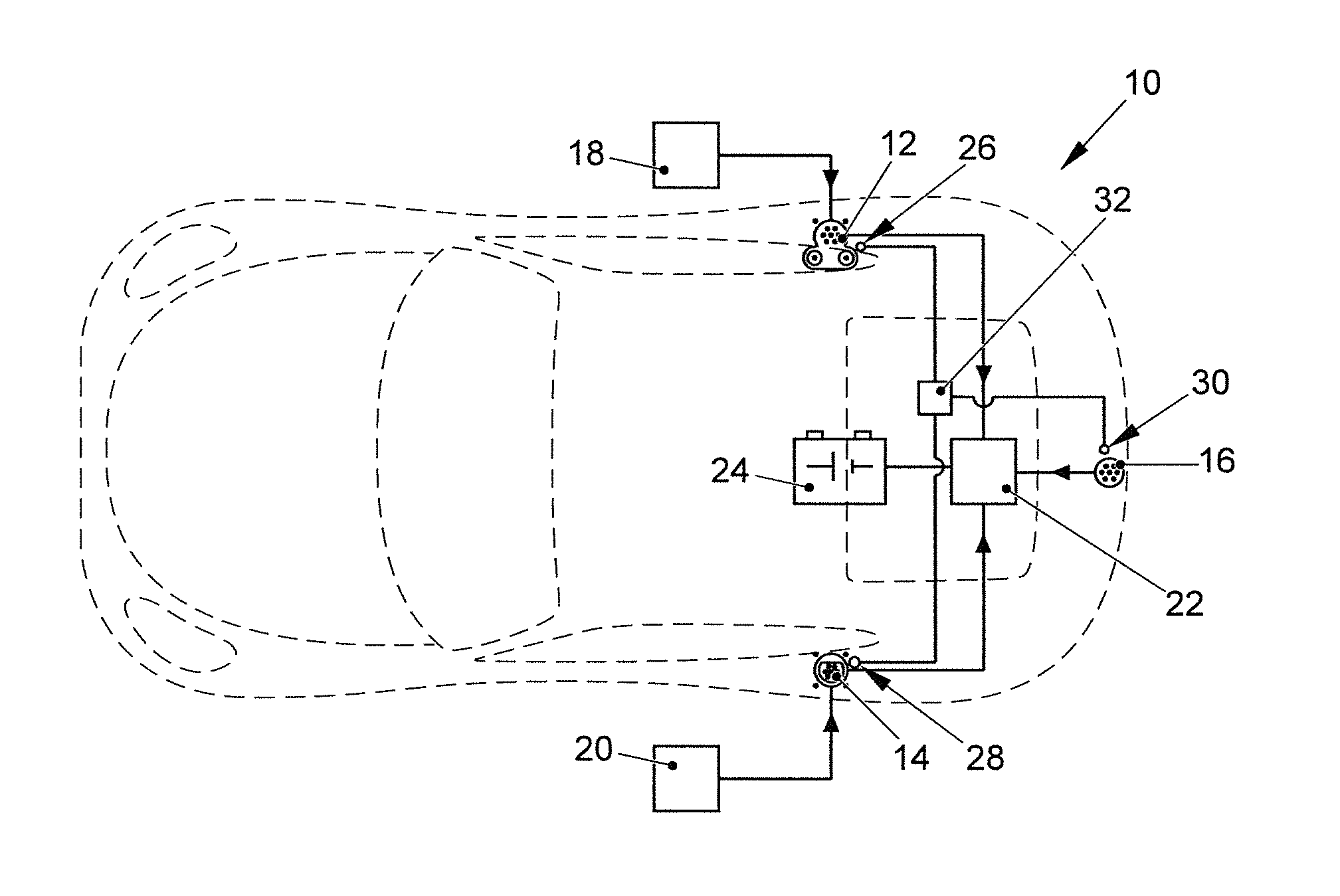

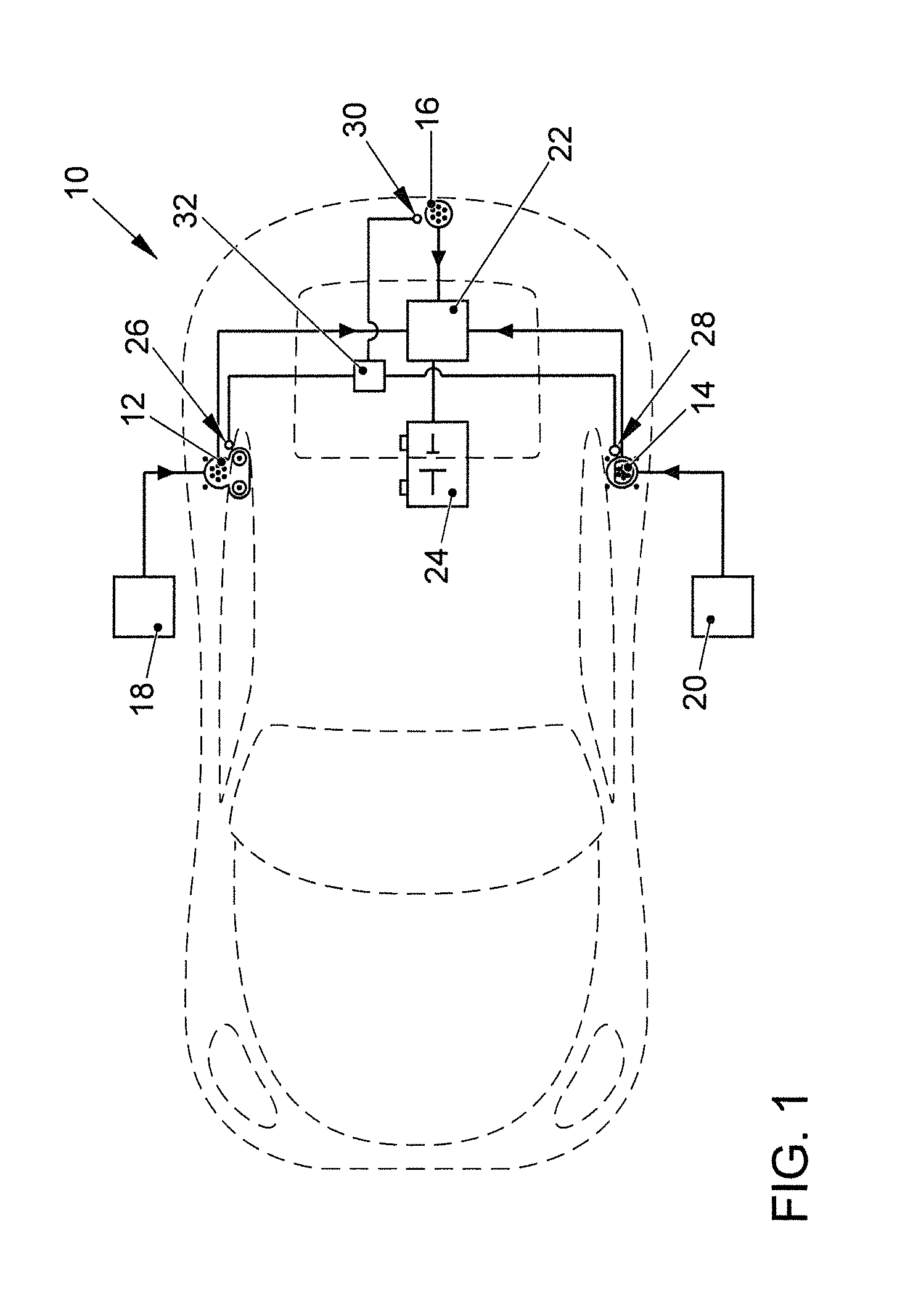

Charging apparatus for a motor vehicle

ActiveUS20170028861A1Limited charge powerAvoid damageCharging stationsSafety/protection battery circuitsElectricityMotorized vehicle

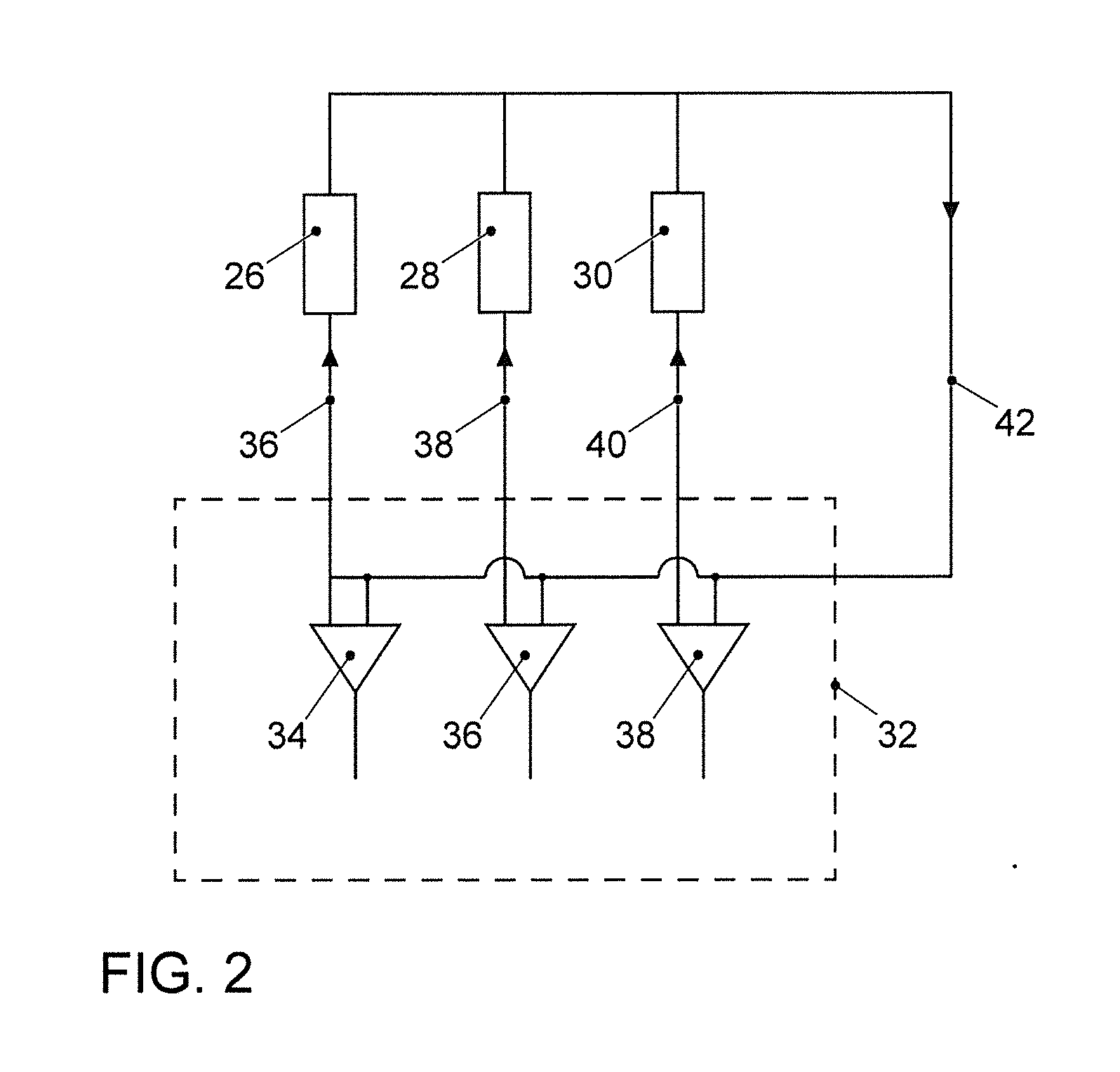

A charging apparatus (22) for a motor vehicle (10) has a plurality of plug connection members (12, 14, 16) to connect the charging apparatus (22) to at least one external electrical energy source (18, 20), a plurality of temperature measuring elements (26, 28, 30) are associated respectively with the plug connection members (12, 14, 16) to detect a temperature of the plug connection members (12, 14, 16), and an evaluation unit (32) electrically connected to the temperature measuring elements (26, 28, 30) to evaluate the detected temperature of the temperature measuring elements (26, 28, 30). The temperature measuring elements (26, 28, 30) are connected to the evaluation unit (32) by a common first connecting line (42), and connectable electrically to the control unit (32) individually by a second connecting line (36, 38, 40) in each case.

Owner:DR ING H C F PORSCHE AG

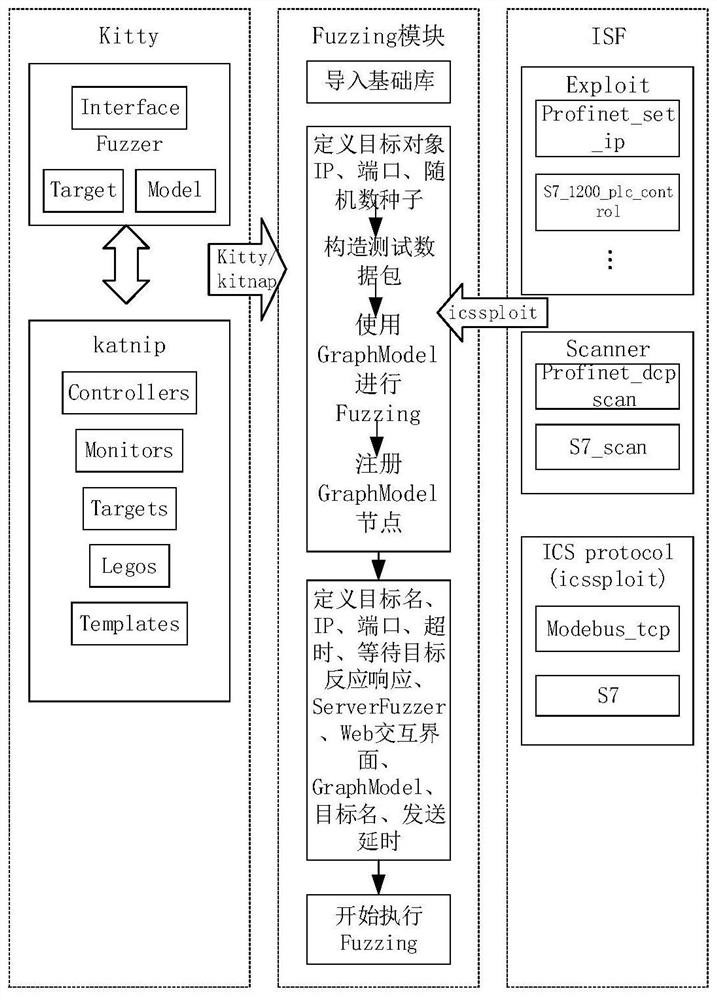

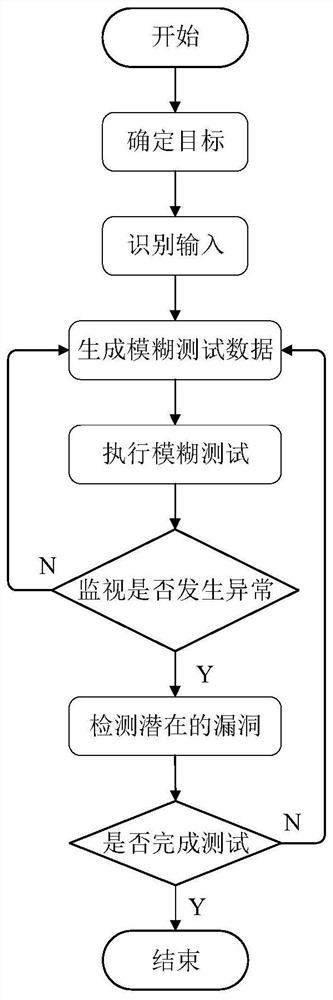

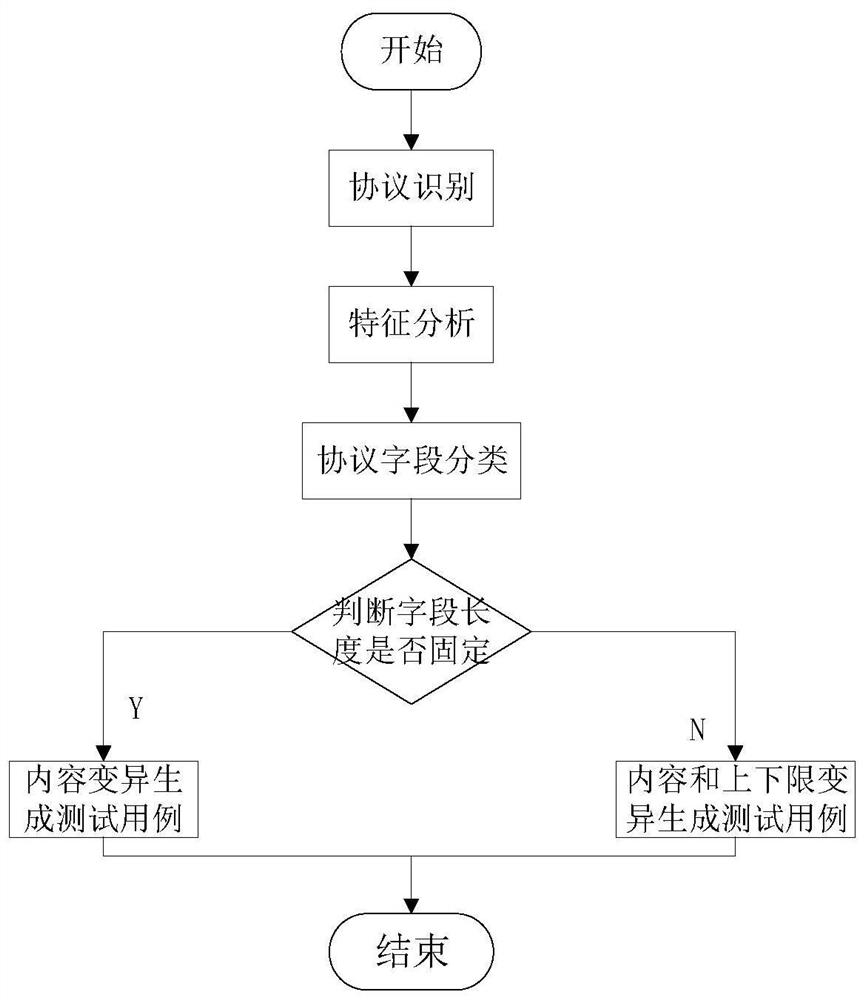

Private protocol fuzzy test case generation method based on byte length classification

ActiveCN112055003AImprove real-time performanceLow technical levelTransmissionProtocol for Carrying Authentication for Network AccessTest case

The invention discloses a private protocol fuzzy test case generation method based on byte length classification, and the method comprises the steps: carrying out the contrastive analysis of the features of a private protocol through an MSA data flow, so as to determine whether the byte length of the private protocol is variable or not; if the private protocol byte length is variable, performing content variation on a variable field of the private protocol byte length; if the private protocol byte length is not changed, performing content variation and byte length upper and lower limit variation on the invariable field; and generating a new test case according to a variation result, and sending the test case to the target device to complete the generation of the test case. According to themethod, vulnerability mining is carried out by combining the characteristics of high real-time performance and high reliability of the private protocol of the industrial control system, so that preventive measures are taken, and the method has relatively low requirements on the technical level of testers, does not need to deeply analyze the protocol, and does not need to have higher requirementson a test technology.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

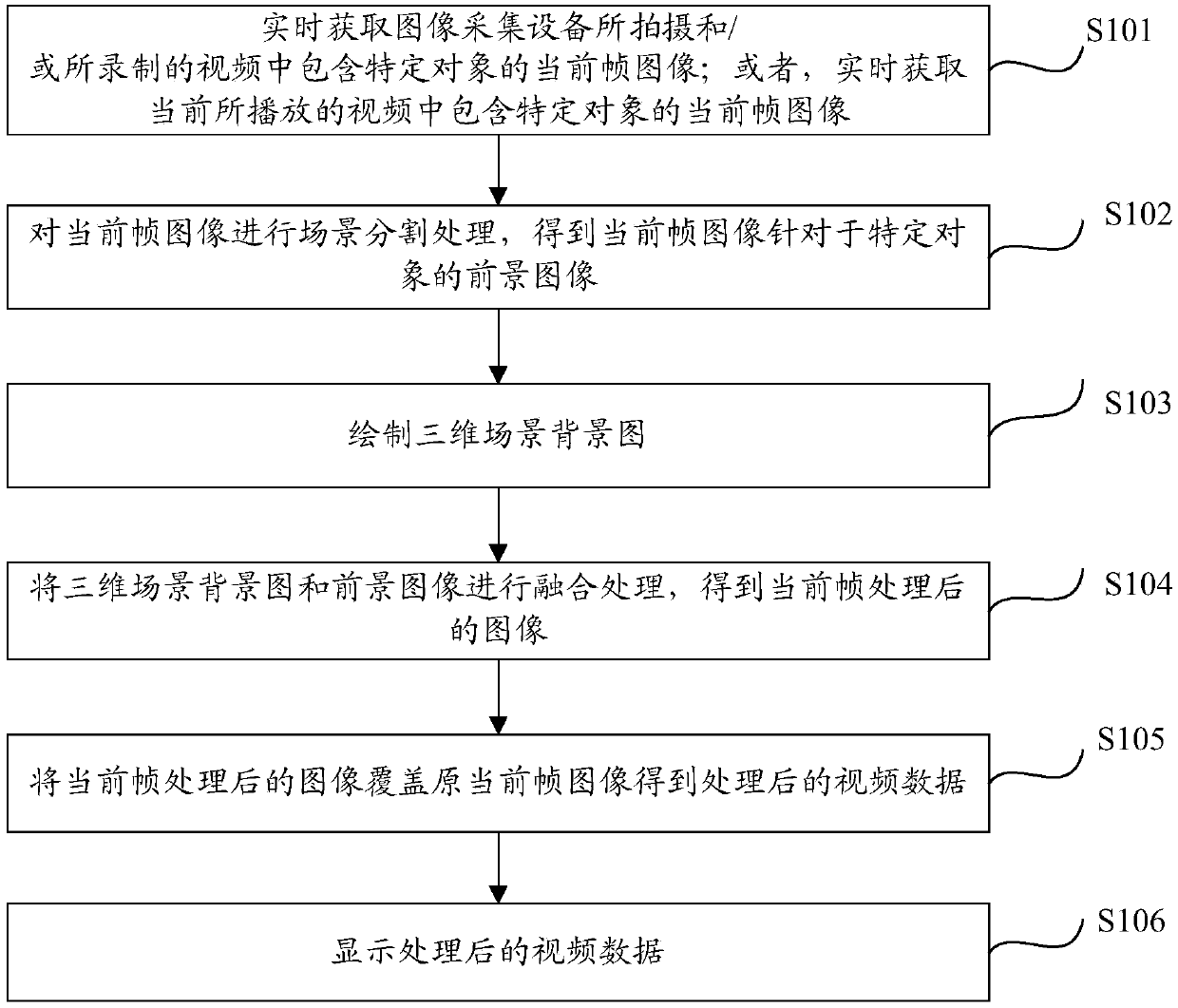

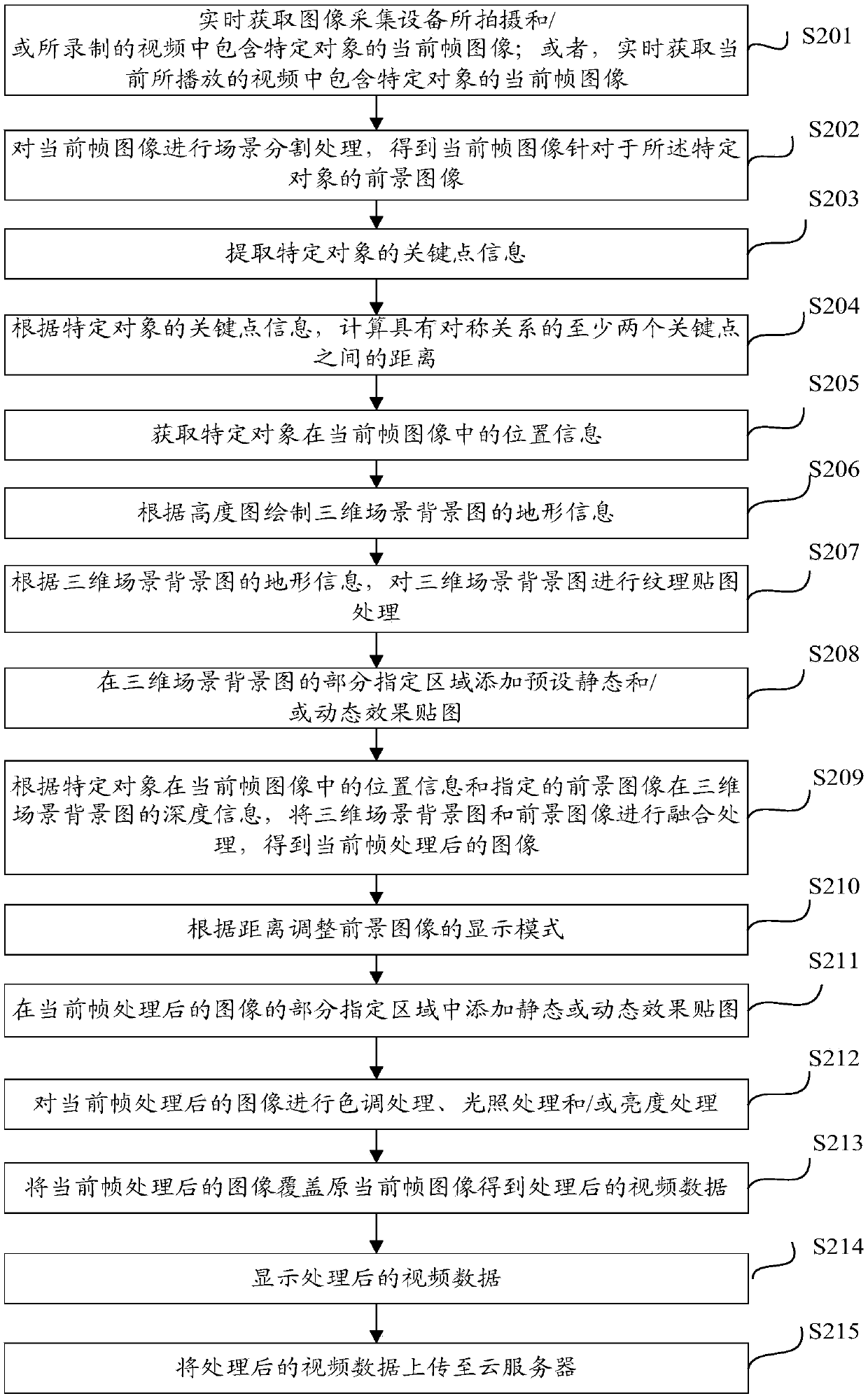

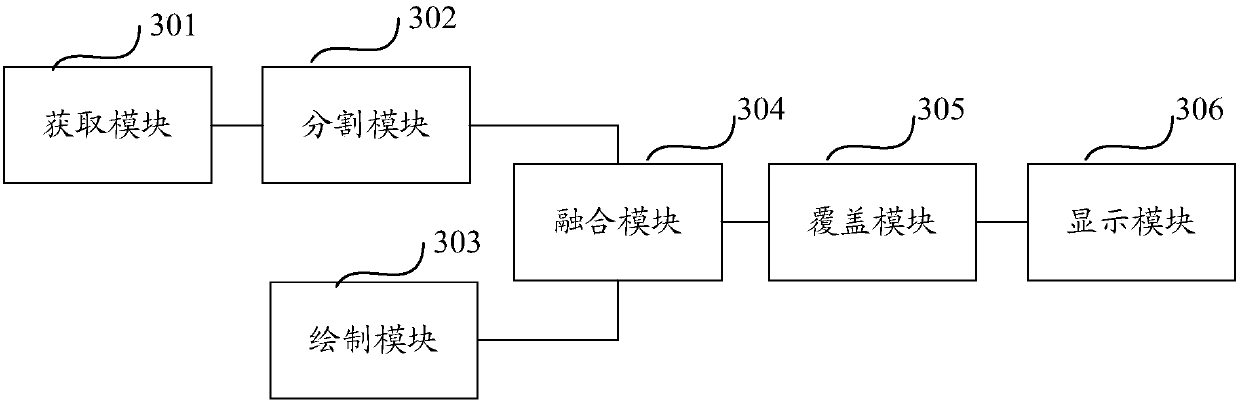

Real-time video data processing method and apparatus for realizing scene rendering, and computing device

InactiveCN107566853ASave user timeAccessible to the general publicSelective content distributionData processingLearning methods

The invention discloses a real-time video data processing method and apparatus for realizing scene rendering, and a computing device. The method comprises the following steps: obtaining a current frame image containing a specific object in a video shot or recorded by an image collection device in real time; or obtaining the current frame image containing the specific object in the currently playedvideo in real time, and performing scene segmentation processing on the current frame image to obtain a current image of the current frame image for the specific object; drawing a three-dimensional scene background diagram; performing fusion processing on the three-dimensional scene background diagram and a foreground image to obtain an image after current frame processing; covering the originalcurrent frame image with the image after current frame processing to obtain processed video data; and displaying the processed video data. According to the real-time video data processing method and apparatus, a depth learning method is adopted to achieve the scene segmentation processing efficiently and accurately. The technical level of the user is not limited, and the user does not need to perform additional processing to the image, so that the time of the user is saved.

Owner:BEIJING QIHOO TECH CO LTD

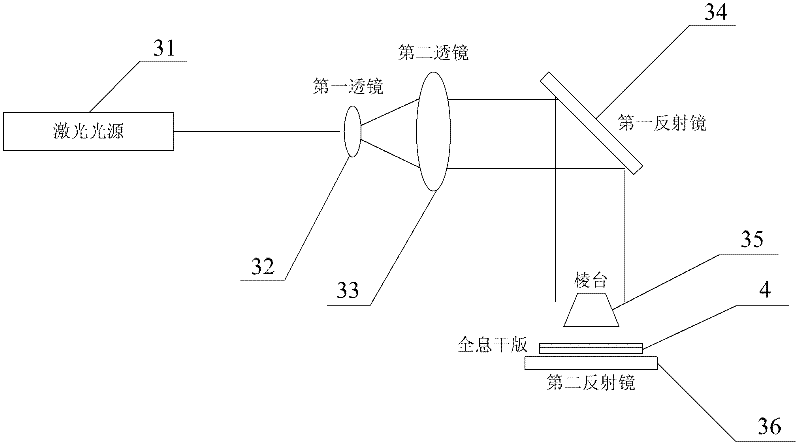

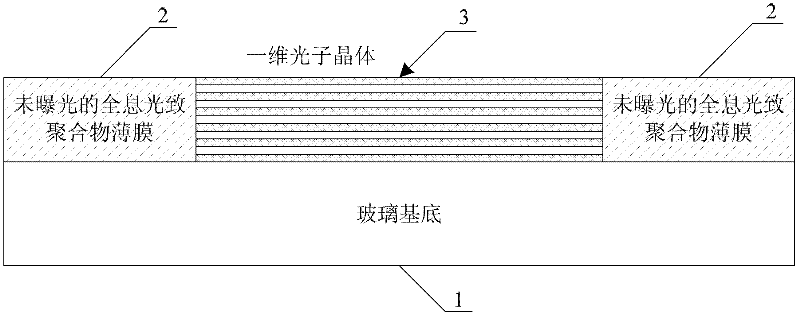

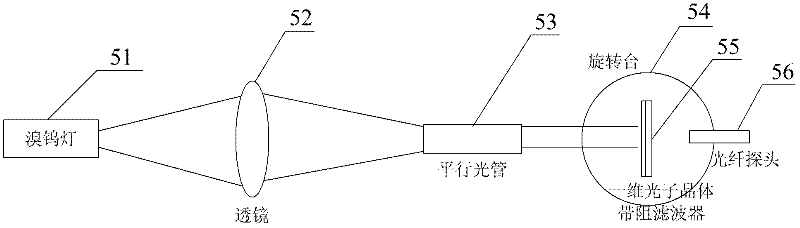

Preparation device and preparation method for one-dimension photonic crystal band-stop filter

InactiveCN102520481ALow technical levelLow technical requirementsOptical waveguide light guidePhotonic crystalLight beam

The invention discloses a preparation device and a preparation method for a one-dimension photonic crystal band-stop filter. The preparation device comprises a laser light source, a light beam expansion unit, a first reflection mirror and a second reflection mirror, wherein the included angle between the first reflection mirror and the horizontal plane is 44 to 46 DEG C, a red-sensitive photopolymer holographic plate to be treated is placed on the second reflection mirror, incidence light emitted out by the laser light source forms parallel beam expansion light after passing through the light beam expansion unit, the beam expansion light is directly emitted onto the holographic plate through being reflected by the first reflection mirror, the transmitted beam expansion beam is vertically emitted onto the second reflection mirror, the parallel reflection light reflected by the second reflection mirror and the directly emitted beam expansion light form two beams of coherence light in opposite directions inside the holographic plate, and the holographic plate is exposed. The preparation device has the advantages that a light path is simple, the cost is low, in addition, only the single beam light is adopted to be vertically emitted onto the ed-sensitive photopolymer holographic plate, and then, the second reflection mirror is utilized, so two beams of coherence light: the upper beam of coherence light and the lower beam of coherence light are formed inside the holographic plate, and the operation is very convenient.

Owner:NINGBO UNIV

Field welding and stabilizing heat treatment method of thick-wall pipeline

ActiveCN101564802BLow technical levelWith construction conditionsArc welding apparatusFurnace typesButt weldingSulfur

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Foamed glass ceramic material for wall and its production process

InactiveCN1167640CImprove performanceImprove mechanical propertiesConstruction materialCeramic materials productionMetallurgyGlass-ceramic

The present invention discloses a nucleated foamed glass wall body material, which is characterized byt aht its composition contains glass powder whose grain size d(0.9) is less than 130 meshes, flyash whose grain size d(0.9) is les than 120 meshes and non-metallic mineral powder whose grain size d(0.9) is less than 230 meshes. Its preparation method includes: grinding glass powder, flyash and non-metallic mineral powder, adding water and mixing them, under the condition of containing water content pressing and forming, drying and kilning, cutting blank and forming to obtain the invented product. It is suitable for industrial production.

Owner:NANJING UNIV +1

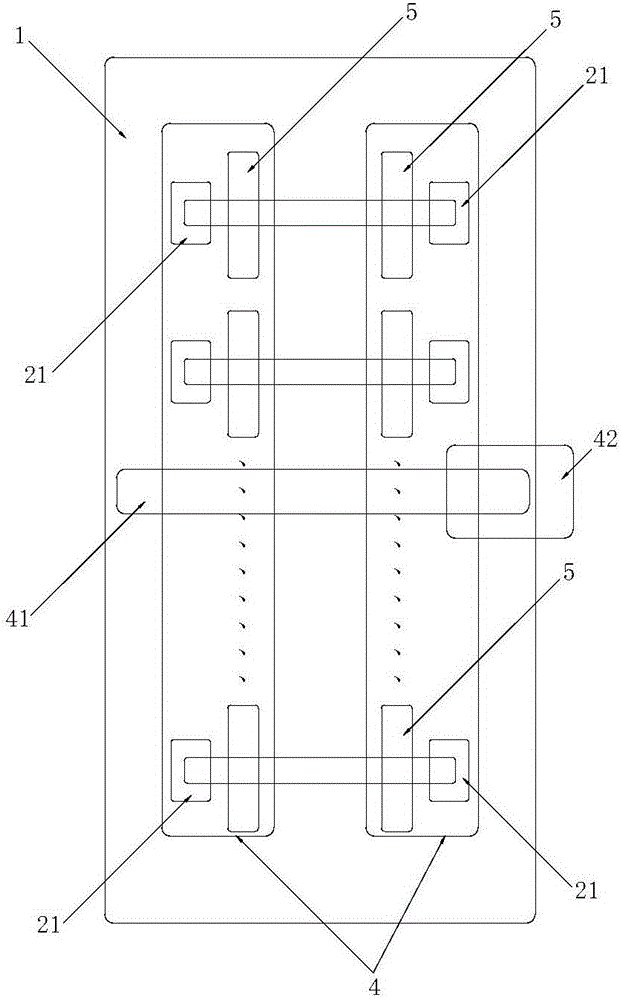

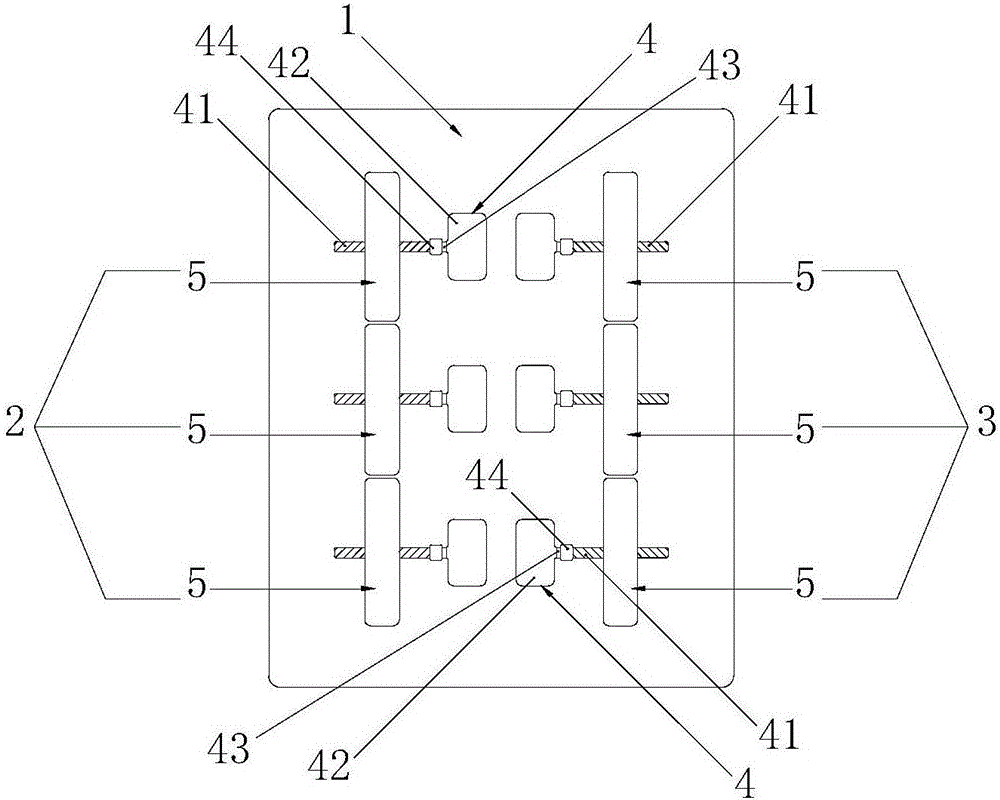

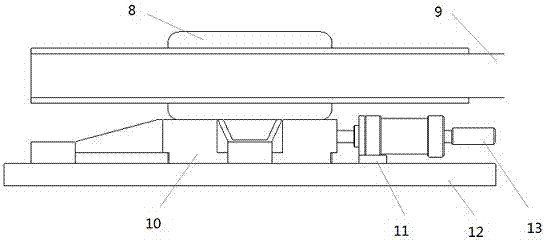

Fixture automatically adjusting specifications of main board and automatic assembling device for automobile radiator core

InactiveCN106425927AReduce labor intensityLow technical levelAssembly machinesWork holdersSocial benefitsReciprocating motion

The invention discloses a fixture automatically adjusting specifications of a main board, an automatic assembling device for the automobile radiator core and an assembling method of the automatic assembling device. The type specifications of an assembled product can be automatically converted, pipes and bands can be automatically distributed, a pipe and band distributing fixture and a main board assembling and binding fixture can be automatically switched on line, and iron wires can be automatically bundled after assembling is carried out. The equipment adjusting time is shortened, the product assembling precision, the yield and the equipment efficiency are improved, the labor intensity of manpower is reduced, the technical level of operators is lowered, and the equipment universality is expanded. Good economic benefits and good social benefits are achieved. A first clamping edge and / or a second clamping edge of the fixture are / is formed by splicing two or more edge strips. A base is provided with a reciprocating mechanism which is connected with the edge strips and used for changing the positions of the edge strips. By changing the positions of the edge strips, the length of the first clamping strip and / or the second clamping strip and the relative position of the first clamping strip and the second clamping strip are adjusted, and the fixture achieves the effect of clamping multiple types of automobile radiator main boards.

Owner:广州坤江汽车配件工业制造有限公司

Automatic checking method for telecontrol point table of dispatching automation system

PendingCN112364043ALow technical levelSimplify the review processData processing applicationsDatabase queryingStationReliability engineering

The invention discloses an automatic checking method for a telecontrol point table of a dispatching automation system. The method comprises the following steps that an automatic checking tool for thetelecontrol point table of the dispatching automation system collects a telecontrol uploading signal; a telecontrol uploading signal voltage grade, an equipment type and scheduling number informationare determined; the description, standardization and integrity of the telecontrol uploading signal are compared with those of a rule base signal; whether missed and excessive signals exist or not is described and judged according to a comparison result, a report form is generated, and signal uploading conditions are distinguished by using colors; and a check report result is output and fed back toa plant-station-side debugging person and a check person. The method is greatly simplified in auditing, saves time and labor, is high in auditing efficiency, can adapt to the auditing of different types of secondary equipment signals, reduces the auditing difficulty, reduces the technical level of auditing personnel, and reduces the error probability caused by subjective reasons.

Owner:GUIZHOU POWER GRID CO LTD

Lead-coated complex porous structures and corresponding method of conductive activation

A complex porous structure of a reticulated foam, felt or fabric types, wherein their metallisation over their entire developed surface, by electrolysis of lead or lead alloys, is made possible by a specific preliminary conductive activation treatment obtained by using two consecutive phases of coating the developed surface of the structures, comprising a first deposition of a conductive polymer, which provides the structures with the required conductivity, and a second thin deposition of conductive lacquer or varnish which ensures the surface protection of the conductive polymer against the deactivating effect of the conductive nature of the latter, due to the cathodic polarisation of the said structures in the electrolytic lead-coating bath.

Owner:S C P S SOC DE CONSEIL & DE PROSPECTIVE SCI

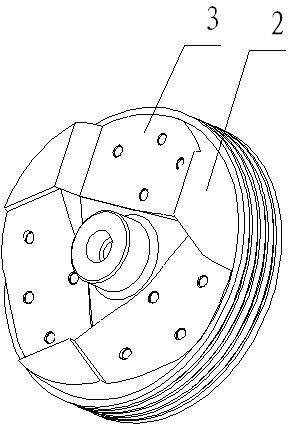

Blade locating structure of small-sized wind power generator

InactiveCN102102642AReduce jitterGuaranteed high speed operationWind energy generationWind motor componentsWind forceElectric generator

The invention relates to a blade locating structure of a small-sized wind power generator, belonging to the technical field of wind power generation. The blade locating structure of the small-sized wind power generator comprises a blade and a rotary flange disc, wherein each blade installation surface of the rotary flange disc is a curved surface which has a same curve with the back surface of the blade. The invention ensures high-speed running of the small-sized wind power generator, reduces fatigue of blade materials due to little jittering of the blade, prolongs the service life of the wind power generator and has high wind power efficiency and high safety.

Owner:陈玉田

Metal die hot working one-time forming device

InactiveCN106493302AReduce labor intensityLow technical levelFoundry mouldsFoundry coresHydraulic cylinderHot work

A metal die hot working one-time forming device is characterized by comprising an upper core installation base, an upper core, jetting nozzles, a right hydraulic cylinder, sliding grooves, a lower core, a protrusion, a lower core installation base, sliding blocks, a left hydraulic cylinder and dead heads, wherein the device is of a symmetrical structure, the left hydraulic cylinder and the right hydraulic cylinder are arranged on the two sides of the device, the left hydraulic cylinder and the right hydraulic cylinder are connected with the jetting nozzles through connecting pins, the sliding blocks are installed below the hydraulic cylinders and installed in the sliding grooves of the lower core installation base on the lower portion of the device, the protrusion is arranged on the center portion of the lower core installation base and sleeved with the lower core, the upper core is arranged at the corresponding position above the lower core, the upper core is installed on the upper core installation base, the dead heads are arranged on the inner sides, making contact with the lower core, of the two sides of the lower core installation base, and the dead heads make contact with the jetting nozzles in the outer sides. The metal die hot working one-time forming device has the beneficial effects that the structure is reasonable, integrated forming is achieved, operation is easy, the labor intensity of workers is lowered, the needed technical level of the workers is lowered, time and labor are saved, the cost is relatively low, and the quality of a cast product can be guaranteed.

Owner:刘勇

Smart multilayer fabric divider

PendingCN107201620AImprove cloth qualityQuality improvementDouble pile fabrics splittingEngineeringMechanical engineering

The invention discloses a smart multilayer fabric divider. The smart multilayer fabric divider comprises a cloth conveying transmission device and a pile cutting device, wherein the cloth conveying transmission device comprises a plurality of cloth conveying guide rollers and a metal detection device; the cloth conveying guide rollers are used for conveying grey cloth to the front of the metal detection device, detecting whether needle breakage occurs in the grey cloth or not, and conveying the grey cloth to a tape knife cutting position; the pile cutting device is used for cutting the grey cloth into two parts from the middle with a tape cutter, wherein the two parts serve as a side A and a side B respectively; on the side A and the side B, cloth is delivered along the same direction through a side A cloth delivery guide roller assembly and a side B cloth delivery guide roller assembly; a visual detection device for detecting the height of lint on the side A and the side B and a servo control device for controlling the height of the lint on the side A and side B are arranged in cloth delivery paths of the side A and the side B along the same direction. By adopting the smart multilayer fabric divider, the technical level of workers is lowered, the whole production flow is simplified, the machining time is shortened, and the production efficiency is increased; meanwhile, single-layer lint having higher cloth quality can be obtained.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

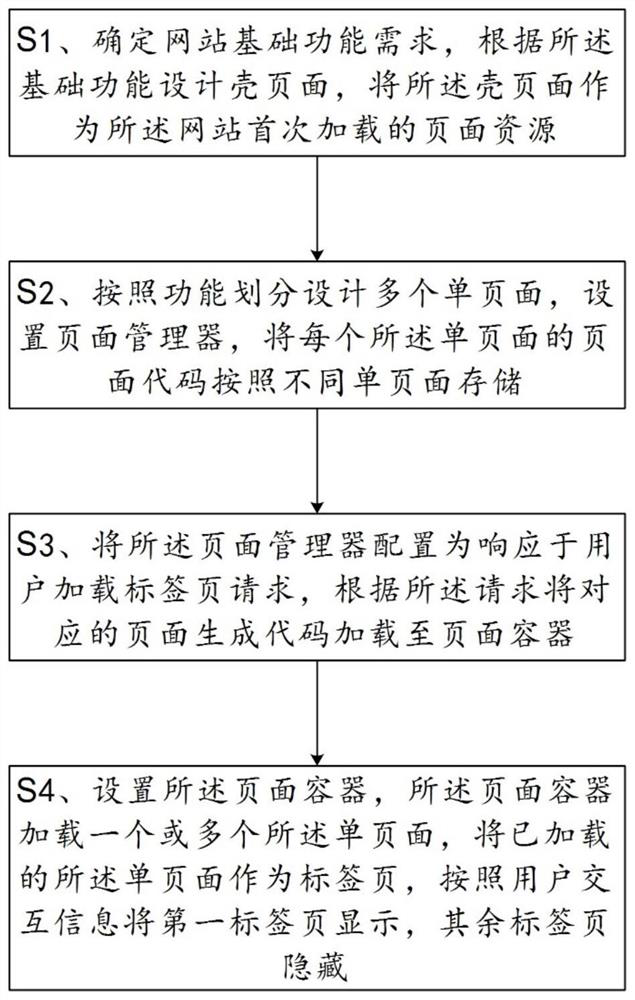

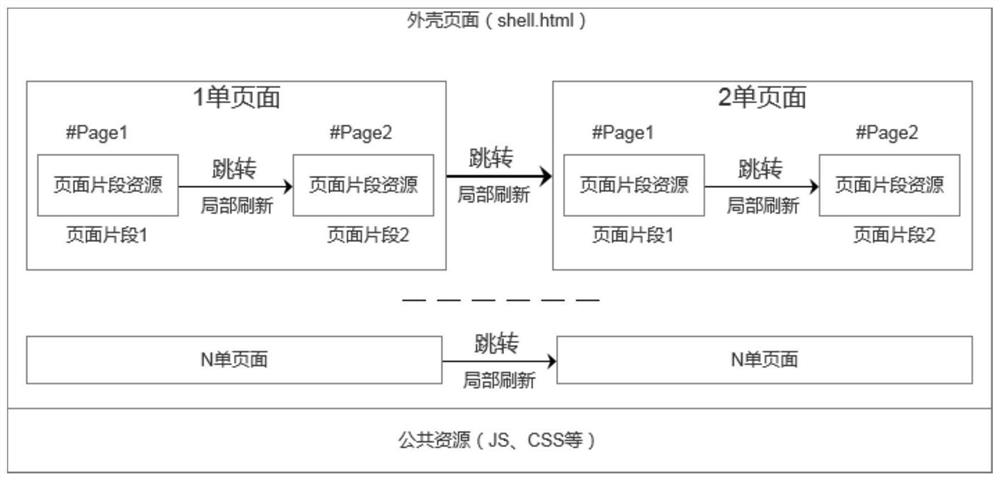

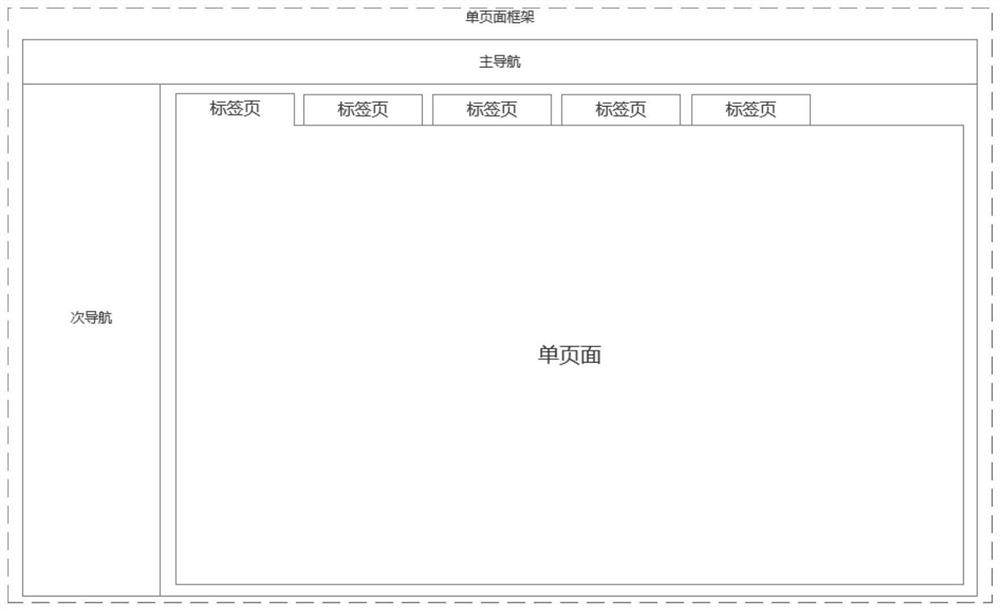

Single-page development method for large website, framework and medium

PendingCN112650965ATakes less time to load for the first timeLow technical levelSoftware engineeringWebsite content managementWeb siteEngineering

The invention discloses a single-page development method for a large website, a frame and a medium, and the method comprises the following steps: designing a shell page according to a basic function, and enabling the shell page to serve as a page resource loaded by the website for the first time; designing a plurality of single pages according to function division, setting a page manager, and storing page codes of the single pages according to different single pages; configuring a page manager to respond to a tab page loading request of a user, and loading a corresponding page code to the page container according to the request; and setting a page container, loading one or more single pages by the page container, taking the loaded single pages as label pages, displaying the first label page according to the user interaction information, and hiding the rest label pages. According to the method, a top-speed, high-efficiency and high-performance single-page development mode can be provided for a large website platform.

Owner:珠海新华通软件股份有限公司

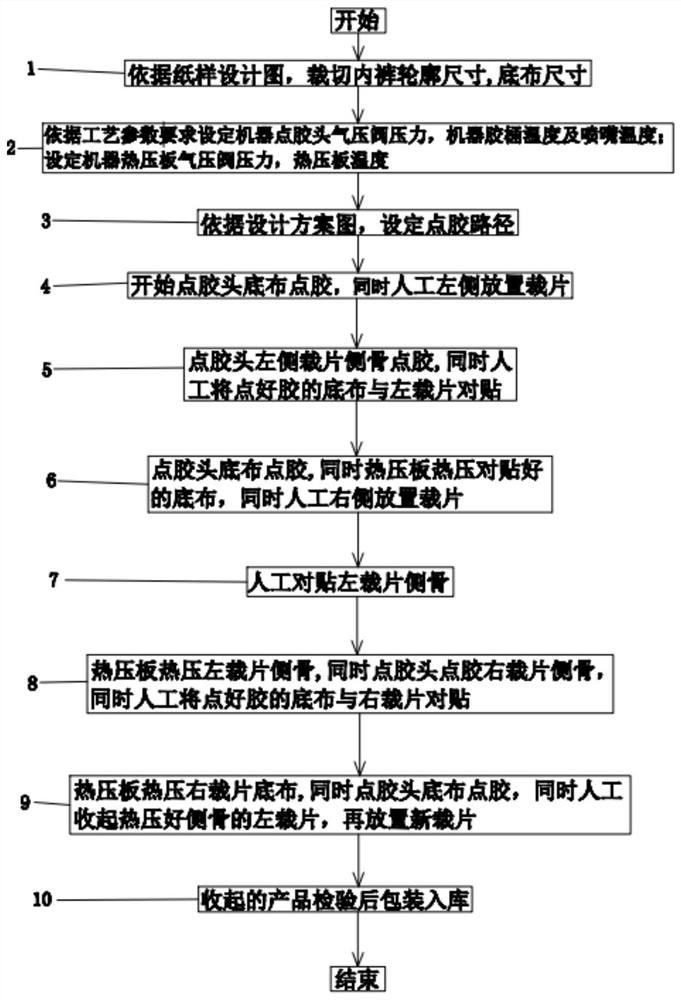

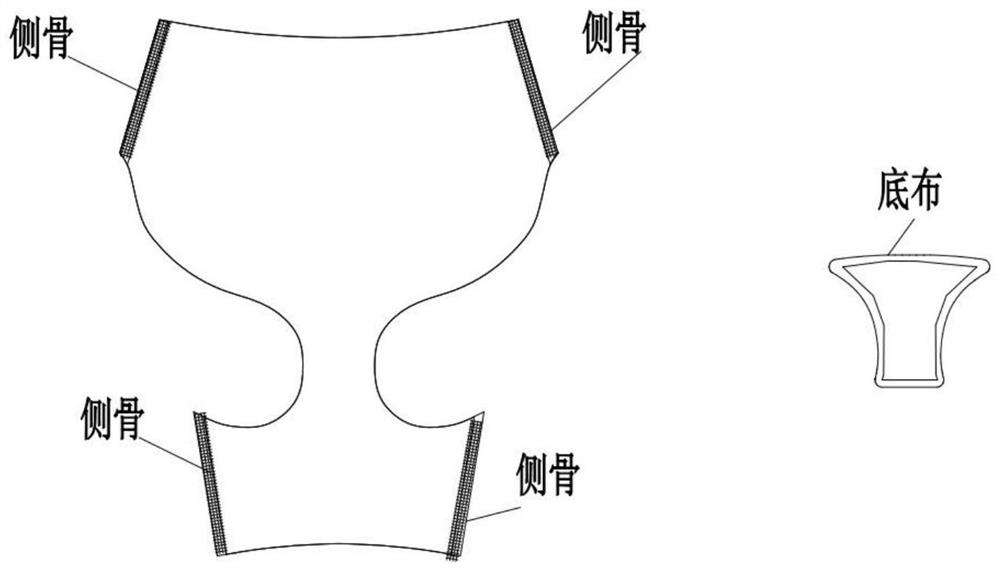

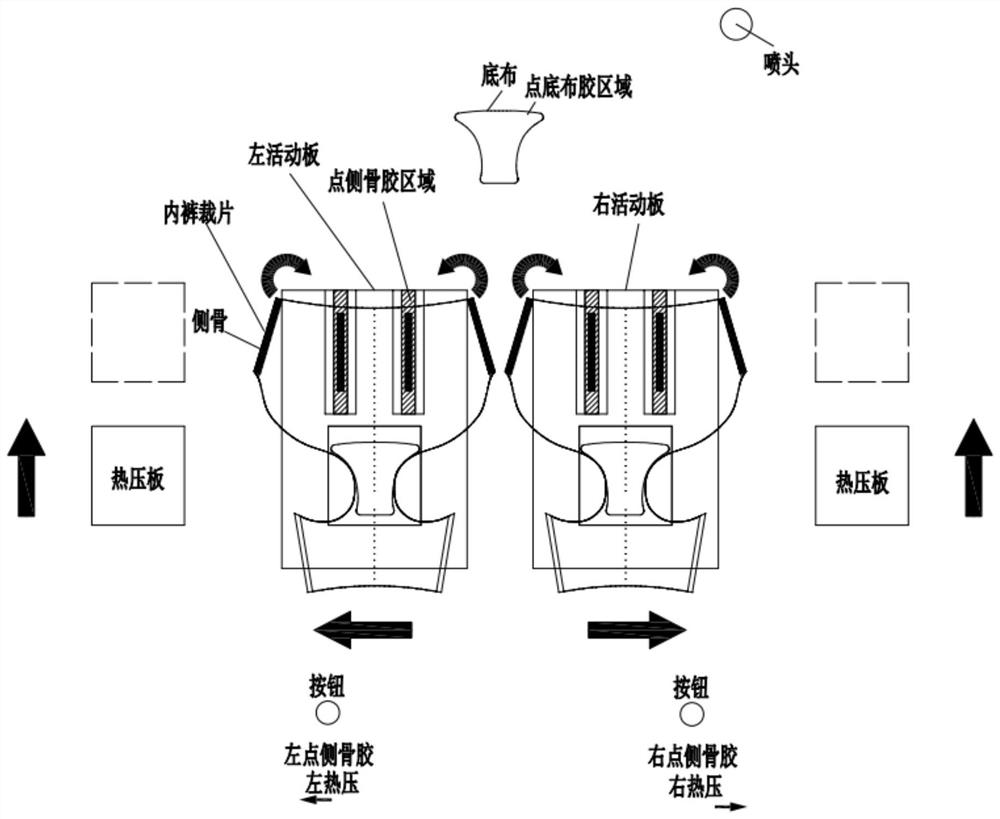

Preparation process for semi-automatically producing seamless underpants

PendingCN113367413AEasy to processReduce manufacturing costUndergarmentsClothes making applicancesEngineeringMechanical engineering

The invention discloses a preparation process for semi-automatically producing seamless underpants, and relates to a preparation process for underpants. According to the preparation process, machine parameters are set according to a paper pattern design drawing, a cut contour size of underpants and the size of base cloth, and a scheme drawing and a dispensing path are designed; a dispensing head conducts dispensing on the base cloth; a cutting piece is manually placed on the left side; the dispensing head conducts dispensing on left-side cutting piece side bone; the dispensed base cloth and the left cutting piece are manually attached; the dispensing head conducts dispensing on the base cloth, and meanwhile, the attached base cloth is subjected to hot pressing through a hot pressing plate; another cutting piece is manually placed on the right side, the side bone of the left cutting piece is manually pasted, then hot pressing is performed on the side bone of the left cutting piece by the hot pressing plate, and at the same time, the dispensing head conducts dispensing on the side bone of the right cutting piece and the glued base cloth and right cutting piece are manually pasted; hot pressing is conducted on the base cloth of the right cutting piece by the hot pressing plate, the dispensing head conducts dispensing on the base cloth simultaneously, and at the same time, the left cutting piece with the hot-pressed side bone is manually collected; then a new cutting piece is placed; and finally, packaging and warehousing are conducted after inspection. According to the invention, a processing flow is simplified, production cost is reduced, and product quality and production efficiency are more easily ensured.

Owner:深圳市奥邦自动化设备有限公司

Chemiluminescence kit for detecting vitamin B12

InactiveCN110441536ALow technical levelLower requirementBiological testingBiotin-streptavidin complexMagnetic bead

The invention discloses a chemiluminescence kit for detecting vitamin B12. The chemiluminescence kit for detecting vitamin B12 comprises a streptavidin magnetic bead suspension, a vitamin B12 standardsubstance, a biotin-labeled vitamin B12 monoclonal antibody, an alkaline phosphatase-labeled vitamin B12 monoclonal antibody, a chemiluminescent substrate, a standard substance diluent, an antibody diluent, a washing solution, and a 96-well ELISA plate. The chemiluminescence kit for detecting vitamin B12 utilizes the technical characteristics of magnetic beads, and combines the biotin-avidin enzyme-linked immunosorbent amplification and a alkaline phosphatase-labeled enzymatic chemiluminescence system to detect the vitamin B12 level in serum, which has very high sensitivity; the chemiluminescence kit for detecting vitamin B12 has more technical and price advantages compared with the prior art; and the chemiluminescence kit for detecting vitamin B12 has the advantages of simple operation,time saving, easy realization of fully automatic operation, no need of expensive special instruments, relatively low requirements on the technical level of the operator and laboratory conditions, which is suitable for promotion and use in the primary hospital, and has great clinical application value.

Owner:NINGBO AUCHEER BIOTECHNOLOGY CO LTD

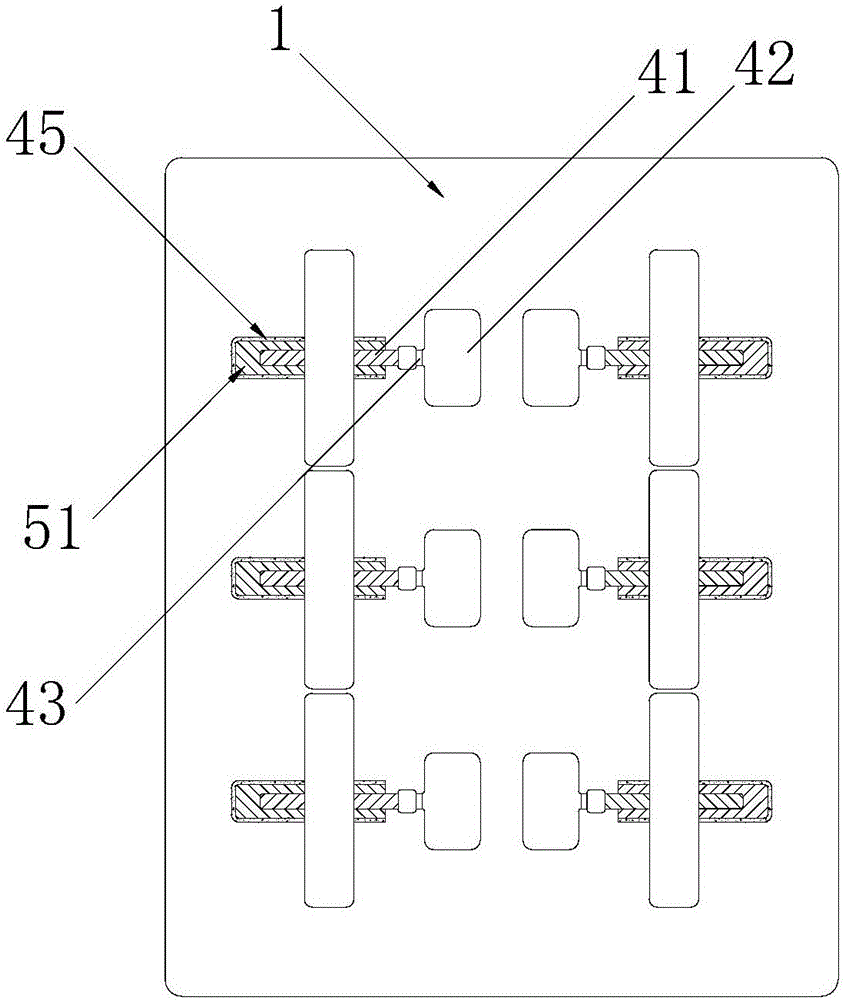

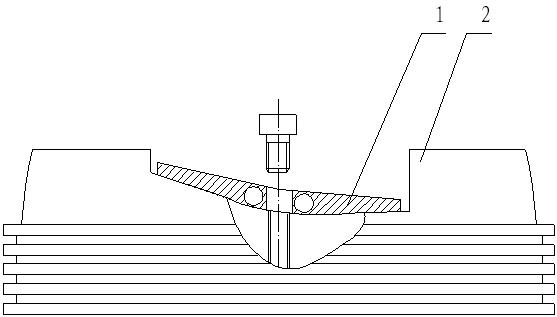

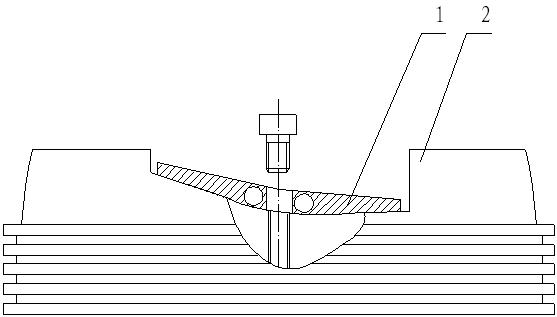

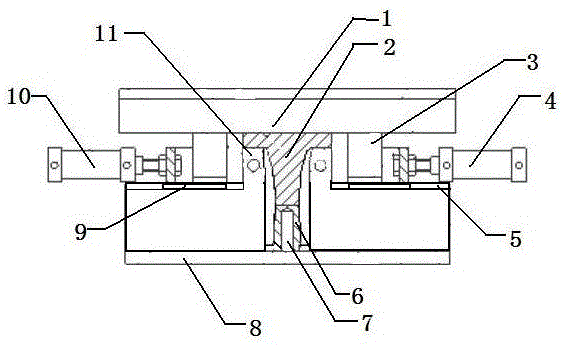

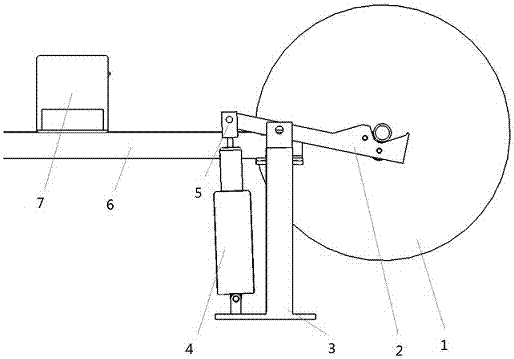

Hedgerow modeling tool with protecting devices

ActiveCN103609346BLow technical levelLower requirementHedge trimming apparatusEngineeringMechanical engineering

A hedgerow modeling tool with protecting devices comprises a first machine frame, a second machine frame, trimming knives, first driving devices, driving mechanisms and the protecting devices. An arc sliding track is arranged at the right end of the first machine frame. An arc sliding block is correspondingly arranged at the left end of the second machine frame. The machine frames are in matching connection through the sliding track and the sliding block. A trimming knife driven by each first driving device is arranged on the bottom face of each machine frame correspondingly. The driving mechanisms are arranged in the machine frames, and the combination angle between the machine frames can be adjusted by changing the position of the sliding block on the sliding track so that the trimming knives can be combined to be in different modeling angles. At least one third machine frame can be arranged between the first machine frame and the second machine frame, the left end of the third machine frame and the left end of the second machine frame are the same in structure, and the right end of the third machine frame and the right end of the first machine frame are the same in structure, so that the trimming range is expanded, the protecting devices are arranged between the machine frames and the trimming knives so that branches and leaves can be prevented from splashing around, and tool damage and accidents can be effectively avoided.

Owner:GUANGXI UNIV

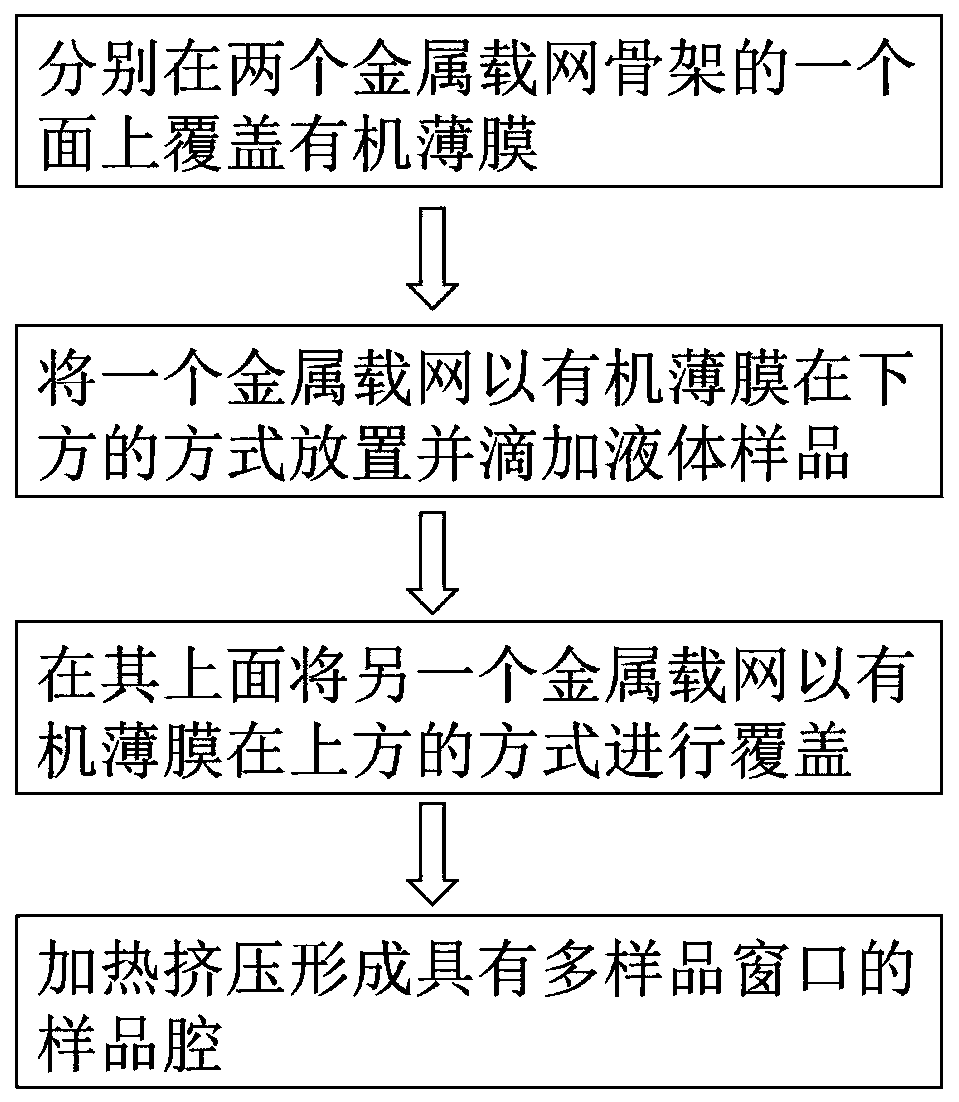

Liquid sample cavity for characterization by transmission electron microscope and preparation method thereof

ActiveCN110632105ALarge window sizeSettle the priceMaterial analysis by transmitting radiationOrganic filmRoom temperature

The invention discloses a liquid sample cavity for characterization by a transmission electron microscope and a preparation method thereof. The method comprises the following steps of: 1) taking two low-melting-point metal grid frameworks for characterization by the transmission electron microscope, and covering one surface of each low-melting-point metal grid framework with an organic film to obtain a metal grid, 2) placing one metal grid in a manner in which the organic film is arranged at the lower part, dropwise adding a to-be-characterized liquid sample from the upper part of the metal grid, and then covering the surface of the metal grid with the other metal grid in a manner in which the organic film is arranged at the upper part, 3) heating the two metal grids until the grid framework starts to soften, performing extruding by an external force until the grid frameworks are fused with each other, and forming a sealed liquid sample window in the crossed grid of the two metal grids, and (4) the grid framework is hardened after the two metal grids are cooled to a room temperature, and carrying out leakage detection to obtain a liquid sample cavity with the plurality of sample windows. The method is based on the low-melting-point metal grids, is simple and easy to prepare, low in cost, high in repeatability and simple to use, and can be used for characterizing a liquid environment by the transmission electron microscope.

Owner:SOUTHEAST UNIV

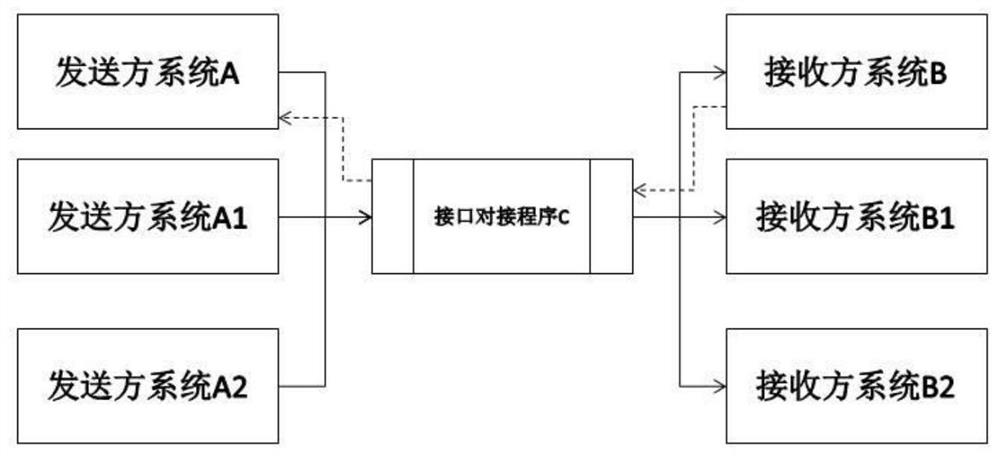

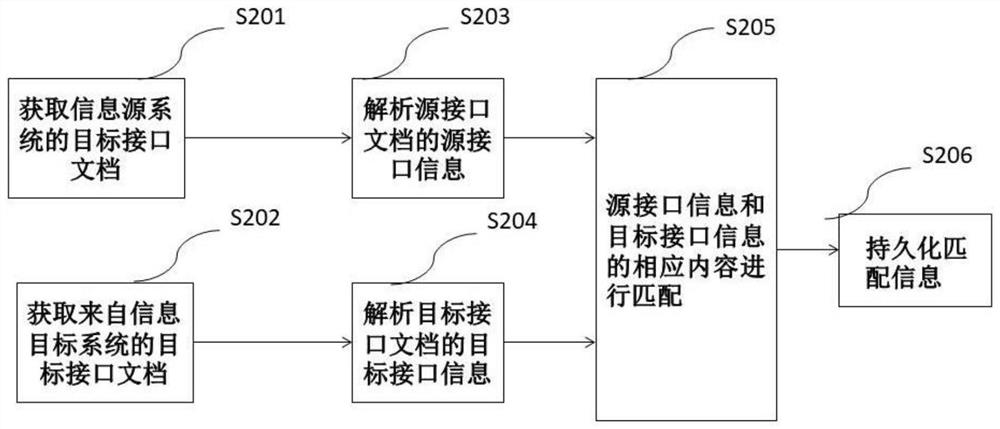

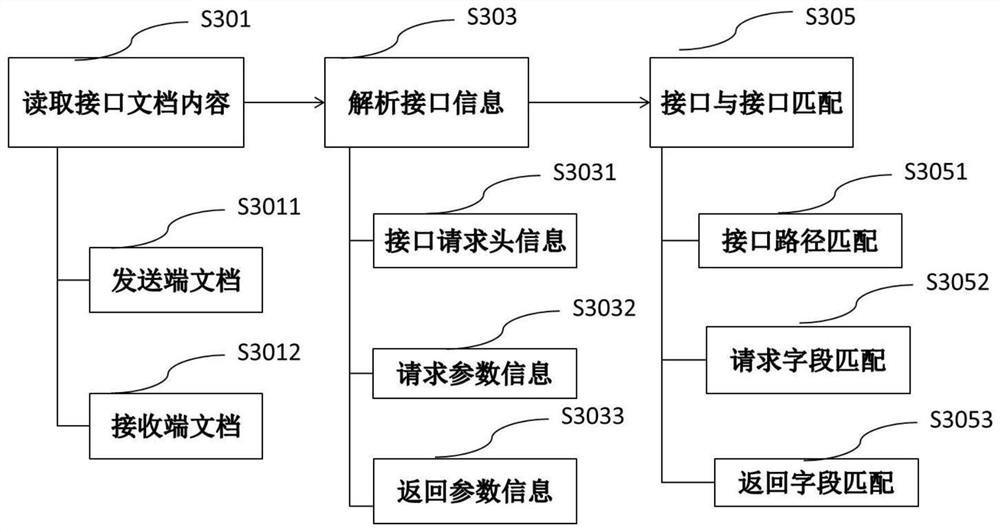

Multi-platform docking method and device, electronic equipment and computer readable medium

PendingCN114721704ALow technical levelSave time and costVersion controlCharacter and pattern recognitionHuman–computer interactionDocumentation

The invention provides a method and a device for multi-platform docking, electronic equipment and a computer readable medium. The method comprises the following steps: acquiring a source interface document from an information source system; obtaining a target interface document from an information target system; analyzing source interface information of the source interface document; analyzing target interface information of the target interface document; matching the corresponding contents of the source interface information and the target interface information to obtain matching information; and carrying out persistence on the matching information. According to the technical scheme provided by the invention, non-technical related personnel can directly set an interface docking scheme, and direct docking between systems can be realized more efficiently.

Owner:HANGZHOU ANCUN NETWORK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com